Manufacture method and rolling device for difference thickness plate

A manufacturing method, a technology of differential thick plates, applied in rolling mill control devices, metal rolling, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0067] Hereinafter, a cold rolling mill will be exemplified, and the first embodiment of the present invention will be described based on the drawings.

[0068] In addition, in the following description, the same code|symbol is attached|subjected to the same component. Their names and functions are also the same. Therefore, their detailed descriptions will not be repeated.

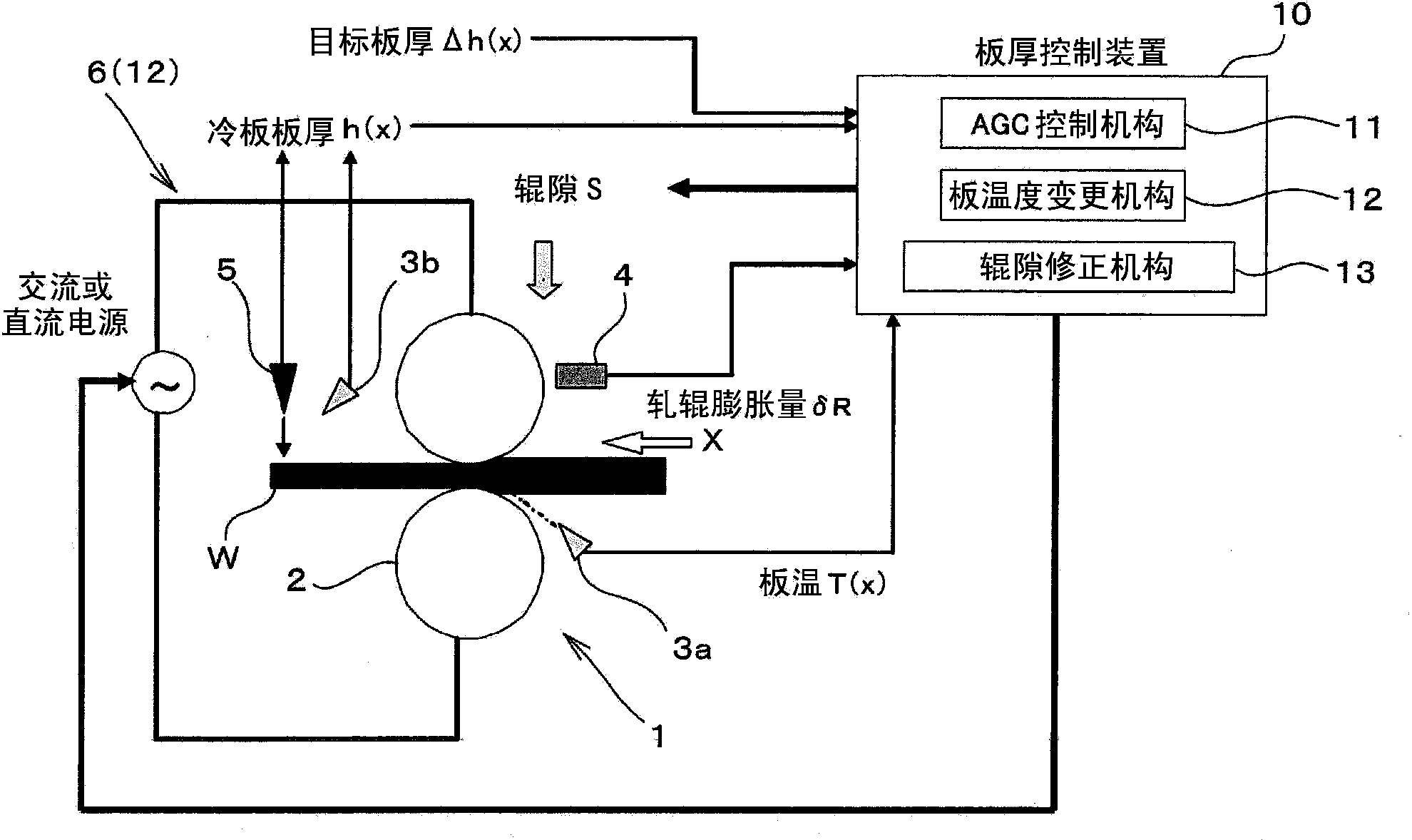

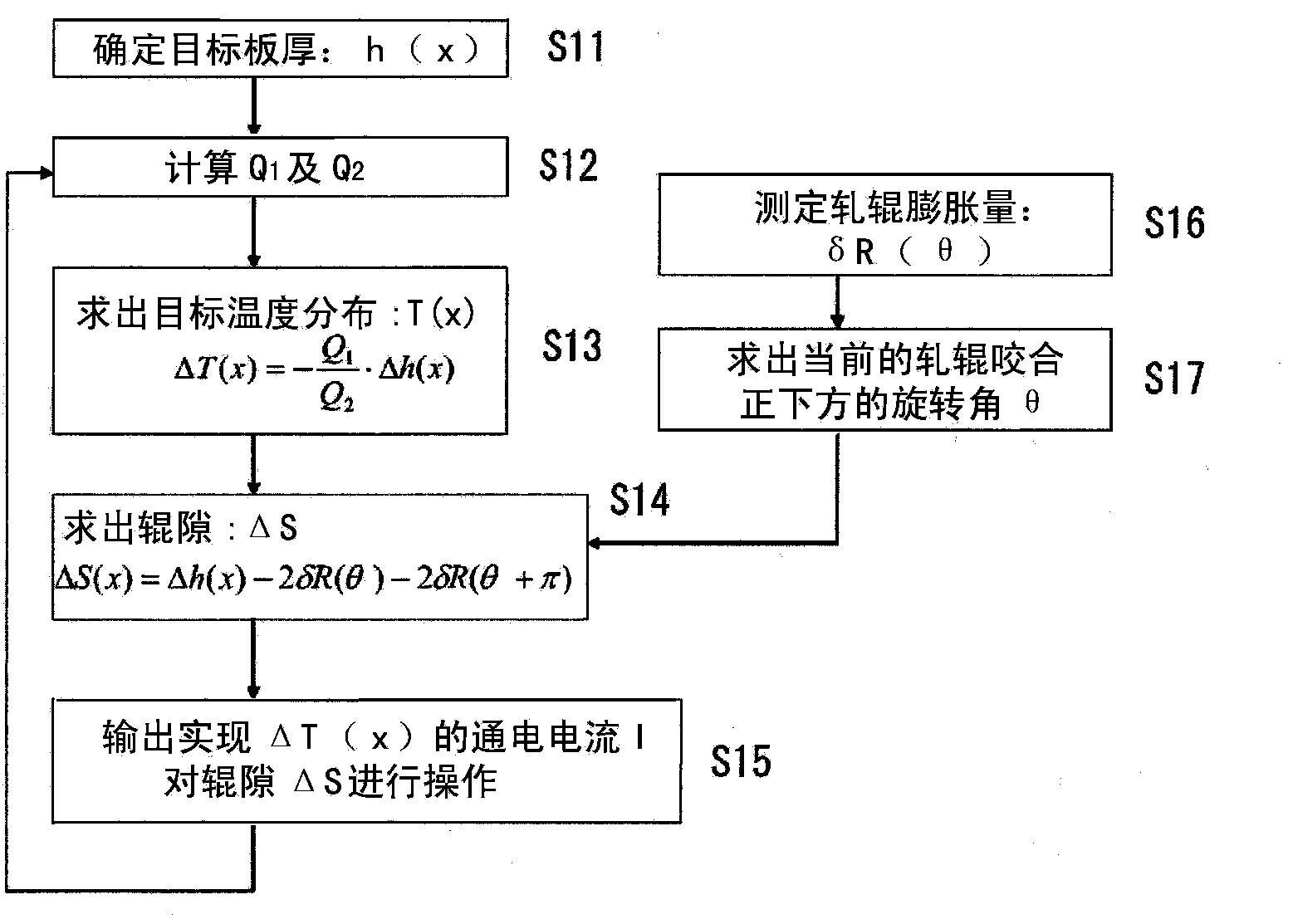

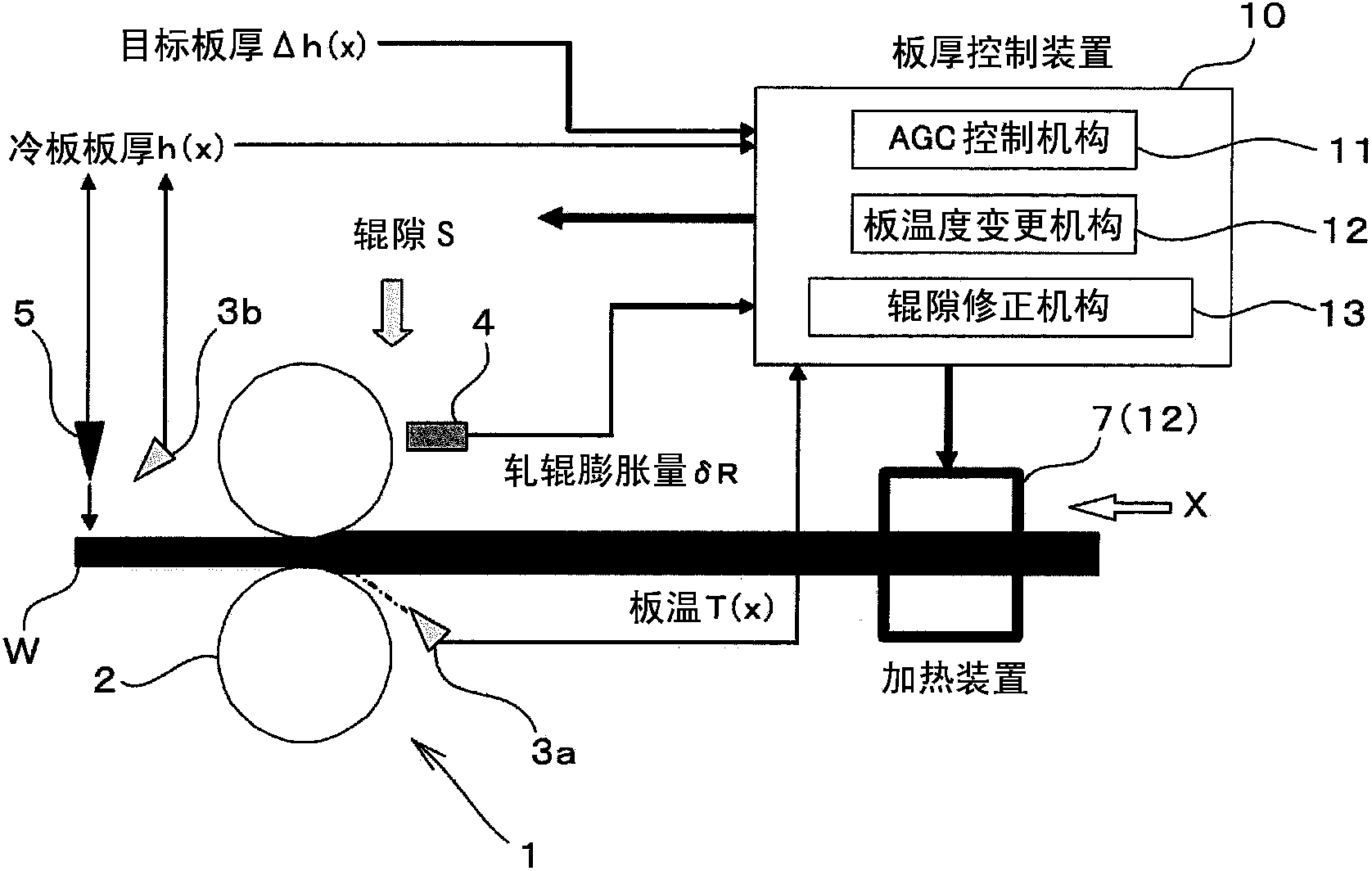

[0069] figure 1 It is a figure which schematically shows the rolling mill 1 (cold rolling mill) with which the rolling apparatus of this invention is equipped. This rolling mill 1 includes a pair of work rolls 2, 2, and by the pair of work rolls 2, 2, a rolling material W such as a steel material is rolled while moving in the arrow X direction to manufacture a differential thickness plate.

[0070] The differential plate of this embodiment is a plate whose plate thickness varies at very short pitches (tens of m to several m) in the longitudinal direction of the rolled material W (length: several thousa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com