Hydraulic fixture for four-hole drilling for end tooth flange yoke of drive shaft

The technology of hydraulic clamp and flange fork is applied in the field of hydraulic clamp for drilling four holes in the flange fork of the transmission shaft, which can solve the problems of reducing the overall efficiency of the production line, time-consuming and laborious clamping work, high labor intensity, etc. The effect of saving processing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

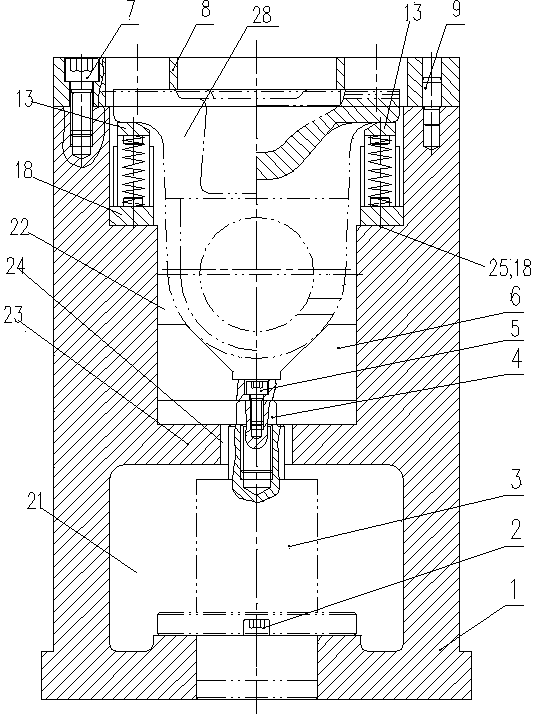

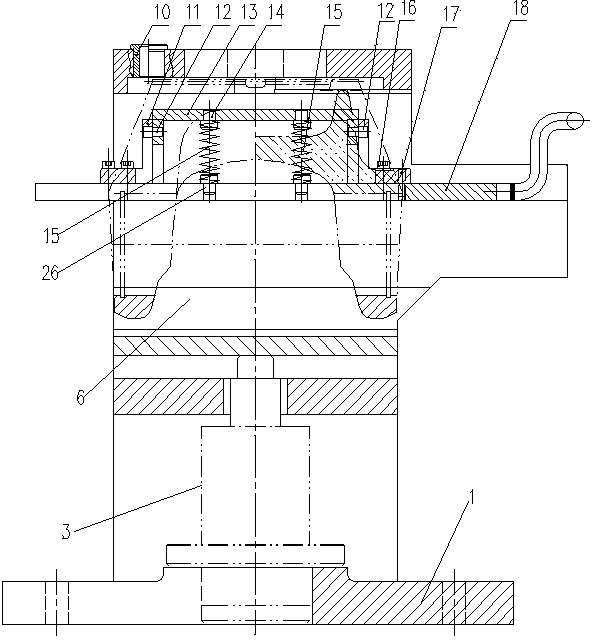

[0010] Such as figure 1 with figure 2 As shown, the transmission shaft end tooth flange fork drill four-hole hydraulic clamp of the present invention includes a clamp body 1, and an upper cavity 22 and a lower cavity 21 are arranged in the clamp body 1, and the upper and lower cavities 22, 21 are formed by clamps. Specifically, the cross brace parts 23 in 1 are separated, and the middle part of the cross brace part 23 is provided with a central hole 24; a V-shaped block 6 is slidably connected in the upper cavity 22, and the V-shaped block 6 can slide up and down in the upper cavity 22 and is used for Press the workpiece 28; the lower cavity 21 is provided with a hydraulic cylinder 3, the hydraulic cylinder 3 and the chuck body 1 are fixedly connected by the first hexagon socket head cap screw 2, and the hydraulic cylinder connecting rod 4 protrudes upward from the central hole 24 And it is connected with the V-shaped block 6 through the second hexagon socket cap screw 5 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap