Method for producing beta-hydroxyethyl ethylenediamine

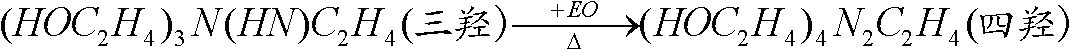

A technology of hydroxyethylethylenediamine and ethylenediamine, which is applied in the field of microreactor technology to carry out the process, can solve the problems of high energy consumption, large liquid return flow, and high feed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

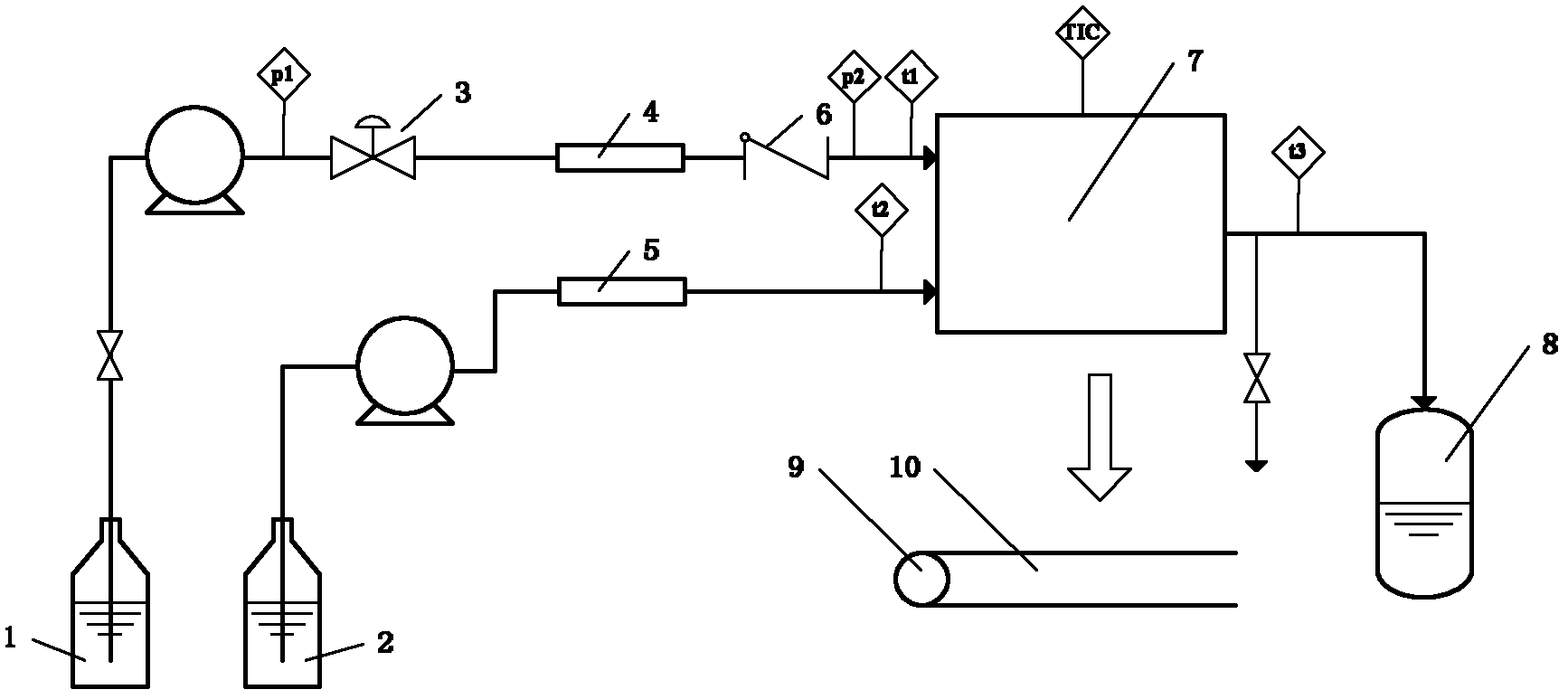

Method used

Image

Examples

Embodiment 1

[0023] Two Series II digital pumps (Chrom Tech, Inc.) are used to control the output of ethylenediamine liquid and ethylene oxide liquid respectively. The ethylene oxide liquid enters the microchannel vaporizer after passing through the back pressure valve and back pressure of 0.3MPa After gasification, it is synchronously and continuously input into the microreactor to react with the ethylenediamine liquid after gasification.

[0024] Microreactor: CNC precision machining preparation

[0025] The pore diameter is 0.3mm, the number is 5, the vertical spacing is 4.5mm

[0026] Micron-level mixing channel is 0.4mm wide and 0.4mm deep

[0027] Effective volume 230μl

[0028] Process conditions: micro-reactor temperature control 100℃

[0029] Environment temperature 12℃

[0030] Reaction pressure

[0031] Digital pump flow rate of ethylenediamine 4.00ml / min

[0032] EO flow rate setting is 0.50ml / min, actual output is 0.33ml / min

[0033] Feed ethylenediamine and ethylene oxide molecular ratio 9...

Embodiment 2

[0045] The process is the same as in Example 1.

[0046] Micro reactor: same as example 1

[0047] Process conditions: micro-reactor temperature control 100℃

[0048] Environment temperature 12℃

[0049] Reaction pressure

[0050] Digital pump flow rate of ethylenediamine 3.30ml / min

[0051] EO flow setting is 0.50ml / min, actual output is 0.33ml / min

[0052] The molecular ratio of feed ethylenediamine to ethylene oxide is 7.5:1

[0053] EO consumption rate 75,000 kg·h -1 ·M -3

[0054] Curing temperature and time: 65-75℃, 2, 5, 10, 20min

[0055] Analysis condition: same as example 1

[0056] Implementation results: (If there is no description, it is the mass concentration, other implementations are the same) The conversion rate of ethylene oxide at the outlet of the microreactor is 25.3%, the main product hydroxylamine is 5%, high boiling point 0; 65-75℃, maturation 2, 5, 10, After 20 minutes, the ethylene oxide conversion was 58.1%, 76.1%, 93.0%, 98.6%, β-hydroxyethylethylenediamine 10.6, ...

Embodiment 3

[0058] The process is the same as in Example 1.

[0059] Microreactor: same as example 1

[0060] Process conditions: micro-reactor temperature control 100℃

[0061] Environment temperature 12℃

[0062] Reaction pressure

[0063] Digital pump flow rate of ethylenediamine 6.60ml / min

[0064] EO flow rate setting is 0.50ml / min, actual output is 0.38ml / min

[0065] The molecular ratio of feed ethylenediamine to ethylene oxide is 13.2:1

[0066] EO consumption rate 86,000 kg·h -1 ·M -3

[0067] Curing temperature and time: 90-100℃, 2, 5, 10min

[0068] Analysis condition: same as example 1

[0069] Implementation results: (mass concentration if not specified, other implementations are the same) The conversion rate of ethylene oxide at the outlet of the microreactor is 16.6%, the main product hydroxylamine is 2%, high boiling point 0; 90-100℃, after maturing for 2, 5, and 10 minutes The conversion of ethylene oxide was 47.3%, 87.9%, 96.5%, β-hydroxyethyl ethylenediamine 5.55, 10.88, 12.37%, high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com