Steel wire net rack demolition-free formwork system and manufacturing method thereof

A wire mesh frame, formwork-free technology, applied in building structures, building components, walls, etc., can solve the problems of difficulty and danger, long construction period, low efficiency, etc., and achieve the goal of improving efficiency, simplifying construction, and protecting the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

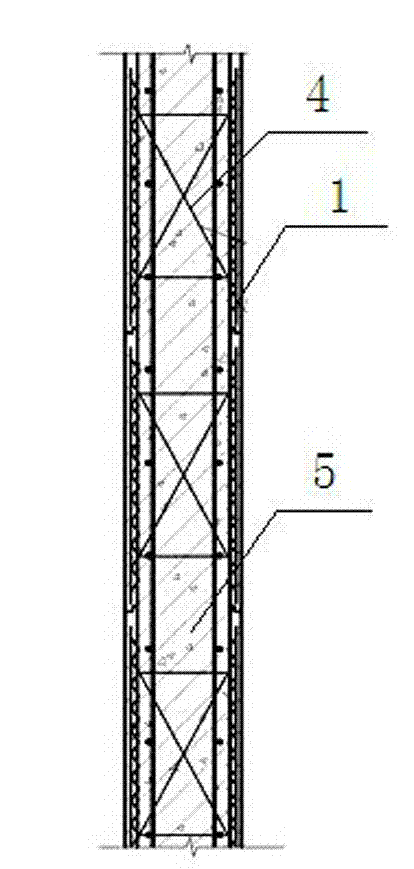

[0015] Such as figure 1 As shown, the two sides are concrete non-demolition formwork with small-diameter and small-pitch steel wire mesh as the skeleton, and the two pieces of non-demolition formwork are hooked with the steel bars 4 shown in the figure to form a stable cast-in-place mold. During cast-in-place construction, just pour concrete into the space in the middle of the mold, and it is not necessary to remove the mold after forming.

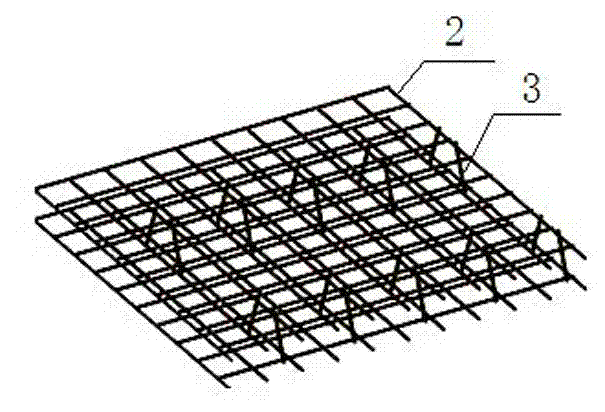

[0016] figure 2 The schematic diagram of the reinforced grid is shown, and the two steel grids are hooked with thicker steel bars to form the skeleton of the cast-in-place concrete mold.

[0017] Generally, steel formwork and wood formwork must be dismantled after the components are formed and permanently fixed, and reused in the next construction. In this construction method, a floor must be cast twice, once for wall panels and once for floor slabs. This brings up many problems. In order to solve these problems, a formwork-fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com