Horizontal boiler

A horizontal boiler, horizontal boiler technology, applied in steam boilers, water-tube steam boilers, fluid heaters, etc., can solve the problems of energy waste, poor performance and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

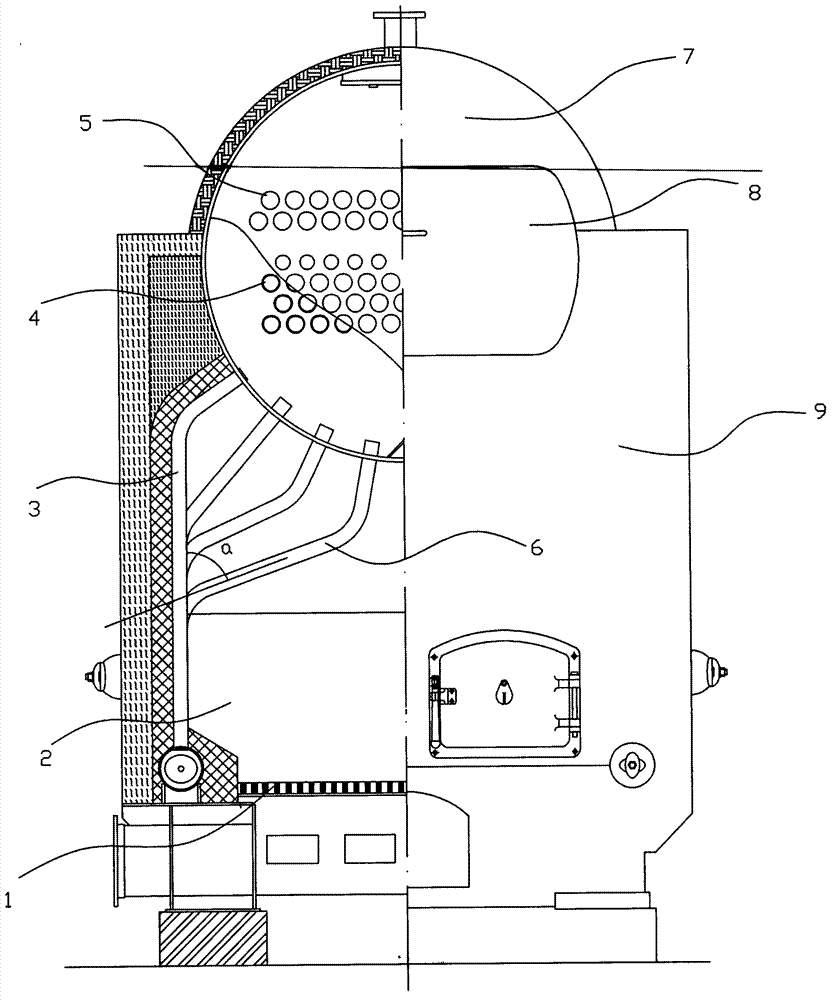

[0008] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0009] It can be seen from the accompanying drawings that the horizontal boiler of this scheme is a three-pass horizontal boiler, including a furnace body 9 and a grate 1 in the furnace body 9, a furnace 2, a water wall and a horizontal drum 7. There are second return smoke pipe 4 and third return smoke pipe 5 inside the drum 7, and a front smoke box 8 and a flue exhaust duct are arranged outside the horizontal drum 7. The water-cooled wall described in this plan is composed of 1-5 branches. A group of water-cooled wall tubes 3 and 1-5 convection tubes 6 as a group are spaced apart from each other. The spacers form the water walls. The convection tubes 6 are parallel to the water-cooled wall tubes 3 at the bottom of the furnace 2, and each group of convection tubes is bent at an ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com