The Expression System and Method of Processing Information of CNC Machine Tool

A technology of numerical control machine tool and expression system, applied in the direction of digital control, electrical program control, etc., can solve problems such as unfavorable operators analyzing and judging state changes, and operators cannot visually and intuitively view the trend or gradual process of state changes. The effect of improving analytical and judgmental skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

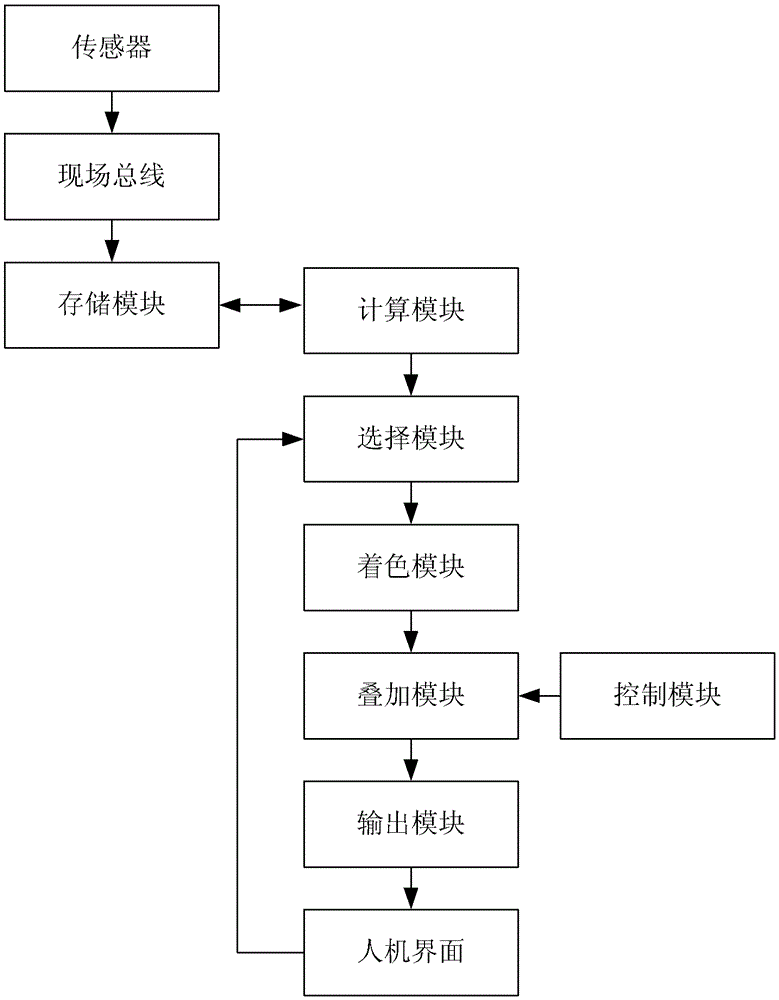

[0029] Such as figure 1 A numerical control machine tool processing information expression system is shown, including: a sensing unit, which is used to detect the physical quantity information of speed, angular velocity, current, voltage, power, heat, frequency and processing length in the process of motor processing workpieces, and various analog After the quantity is collected, it becomes a digital quantity error. After the collection, it is digitized and processed to become a digital quantity error E; the field bus is used to transmit the digital quantity error E returned by the sensing unit to the storage module of the numerical control system, such as CAN, SERCOS, etc.; storage module, used to store digital error E and error increment value ΔE, this module is the memory of the numerical control system, which can be hard disk, memory card, etc.; calculation module, used to calculate the increment of digital error E change, and store the error increment value ΔE in the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com