Anti-bending flexible cable of shearer

A shearer and flexible cable technology, applied in the direction of bendable cables, insulated cables, bendable conductors, etc., can solve the problems of poor bending flexibility, easy to be broken, etc., so as to improve the bending flexibility and increase the bending performance. , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

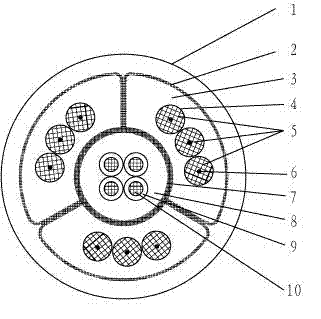

[0009] Such as figure 1 As shown, a flexible cable for a bending-resistant coal shearer includes a power line wrapped in an outer sheath 1, a ground wire 7 and a control line; the power line is composed of a power line conductor 5, and a poly The polyester tape 4, the power line insulation layer 3 wrapped outside the polyester tape 4, and the shielding layer 2 wrapped outside the power line insulation layer 3 are formed. The control line is composed of a control line conductor 10 , an insulating layer 9 and a control line core sheath 8 . Each phase of the power line conductor 5 is composed of three multi-strand tinned copper wire bundles twisted and arranged in an arc shape; a reinforcing core 6 is arranged at the center of the power line conductor 5; Core sheath surface.

[0010] In this embodiment, the outer sheath 1 is extruded from a chlorinated polyethylene material that is flame-retardant, flex-resistant, heat-resistant, and chemical-resistant. The shielding layer 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com