Contraction special-shaped optical fibre composite aerial ground line and method of production

A fiber optic composite, overhead ground wire technology, applied in the direction of optical fiber/cable installation, fiber mechanical structure, etc., can solve the problem that the short-circuit current characteristics cannot meet the requirements, etc., to improve the short-circuit thermal stability characteristics, improve the lightning resistance performance, and improve the tensile strength. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

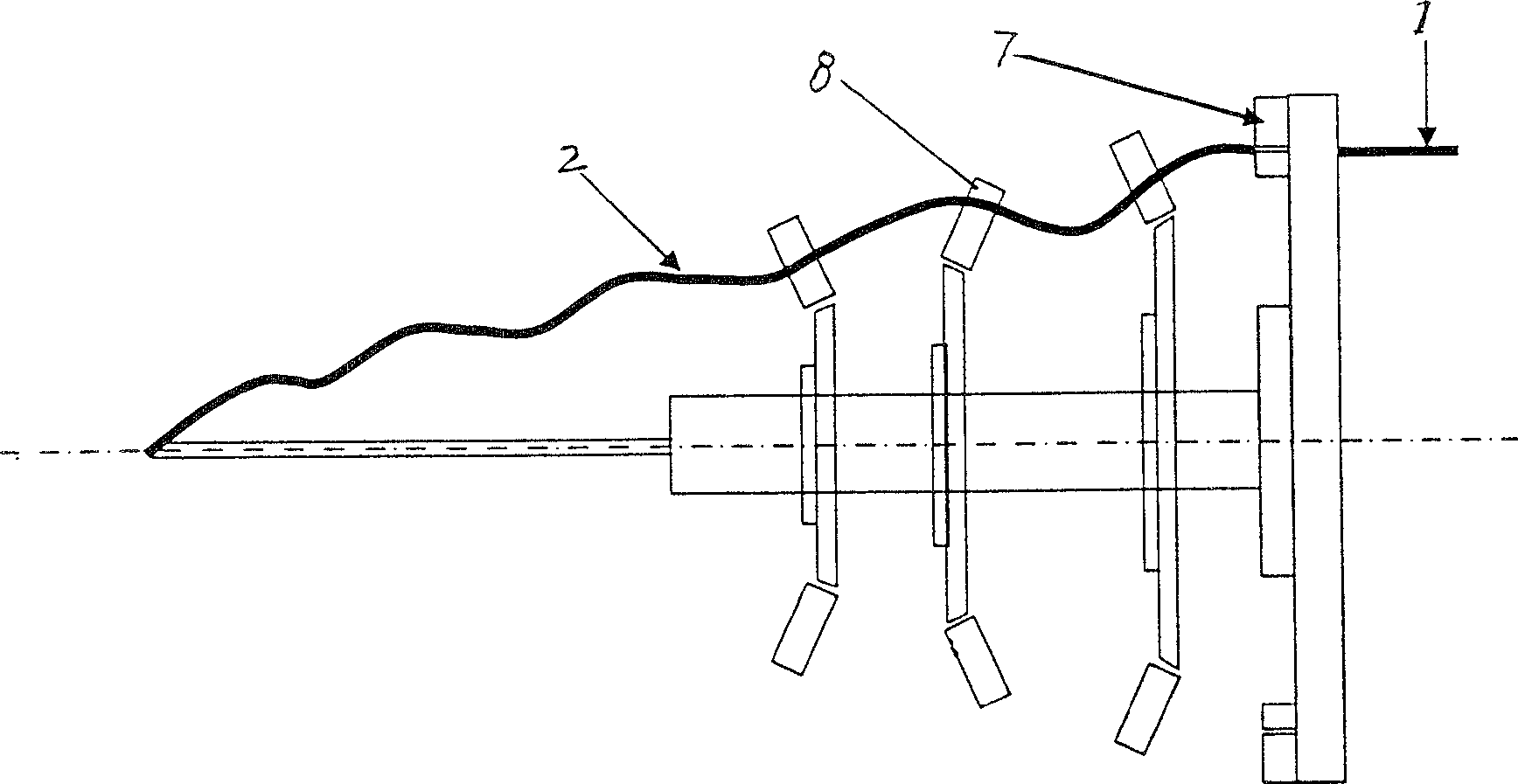

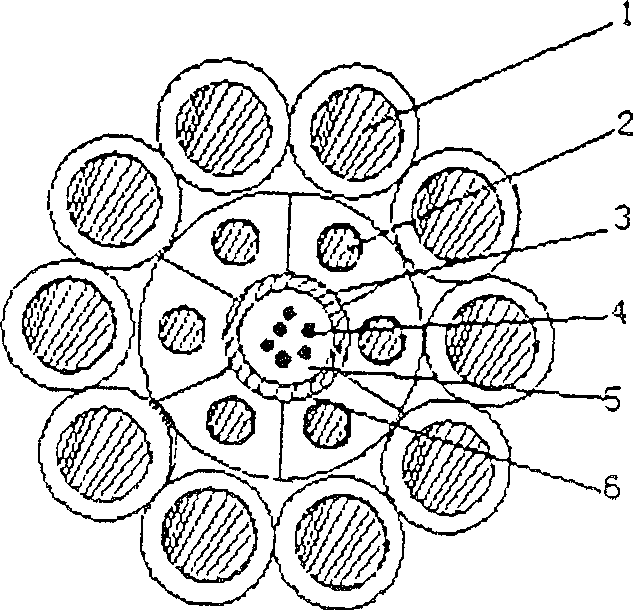

[0026] Refer to attached Figure 1~4 , Compressed special-shaped optical fiber composite overhead ground wire (OPGW) includes several optical fibers 4, optical fiber ointment 5, stainless steel tube 3, anti-corrosion cable ointment 6, compressed special-shaped aluminum-clad steel wire 2, and round aluminum-clad steel wire 1. Several optical fibers 4 and optical fiber ointment 5 are installed in the stainless steel tube 3, and the anti-corrosion cable ointment 6 is filled outside the stainless steel tube 3, and then one or more layers of compressed special-shaped aluminum-clad steel wires 2 and one or more layers can be twisted. Circular aluminum-clad steel wire 1 constitutes a compressed special-shaped optical fiber composite overhead ground wire (OPGW), see attached image 3 ; It is also possible to twist one or more layers of compressed special-shaped aluminum-clad steel wires 2 outside the stainless steel tube 3 to form a compressed special-shaped optical fiber composite ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com