Sand box positioning device

A technology of positioning device and positioning position, which is applied in the direction of mold box, casting equipment, metal processing equipment, etc., can solve the problems of high labor cost, unsuitable core setting accuracy, high manufacturing cost and management cost, etc., to ensure repeatability. The effect of positioning accuracy, high-precision positioning of the sandbox, and simplified fixture tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

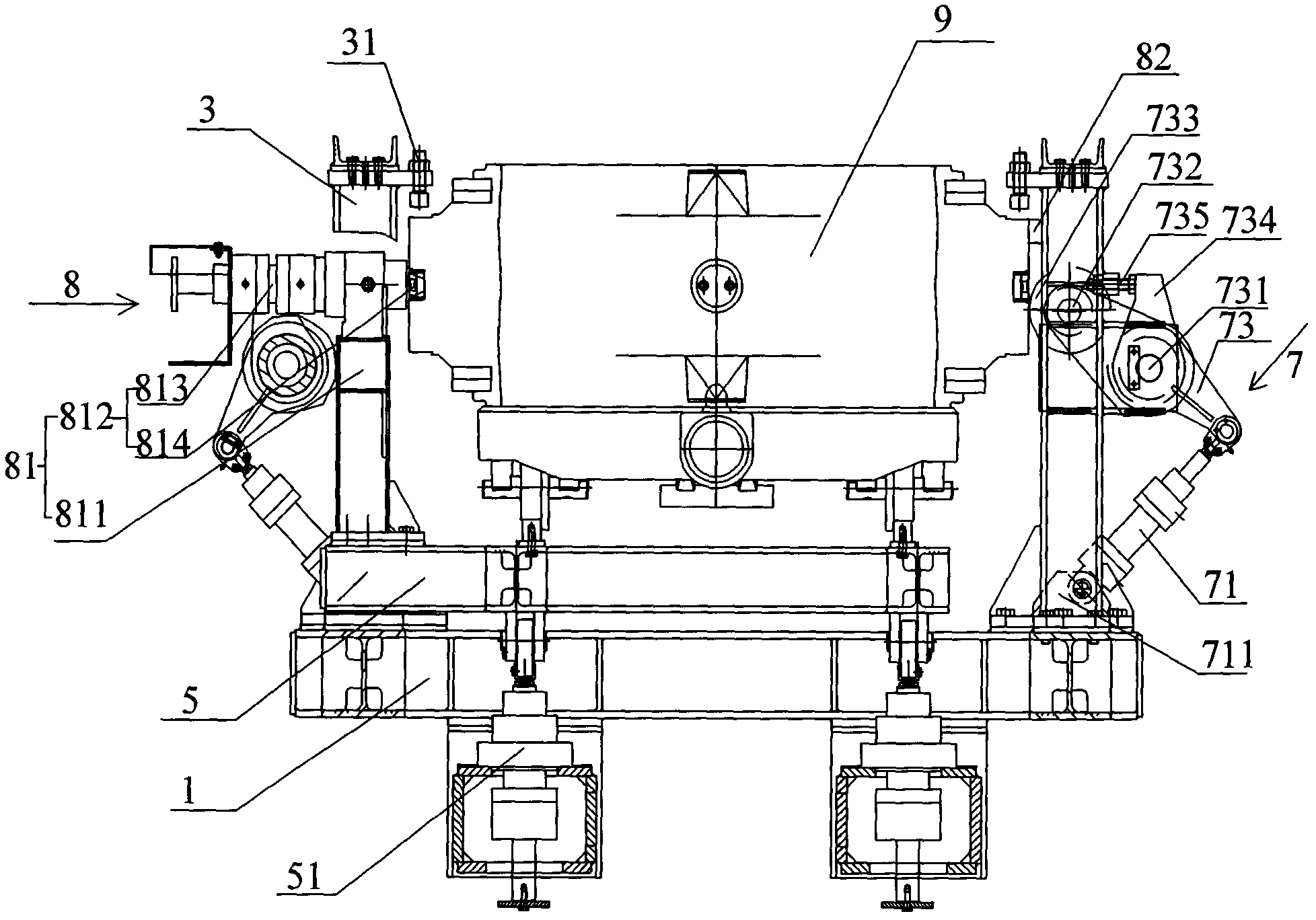

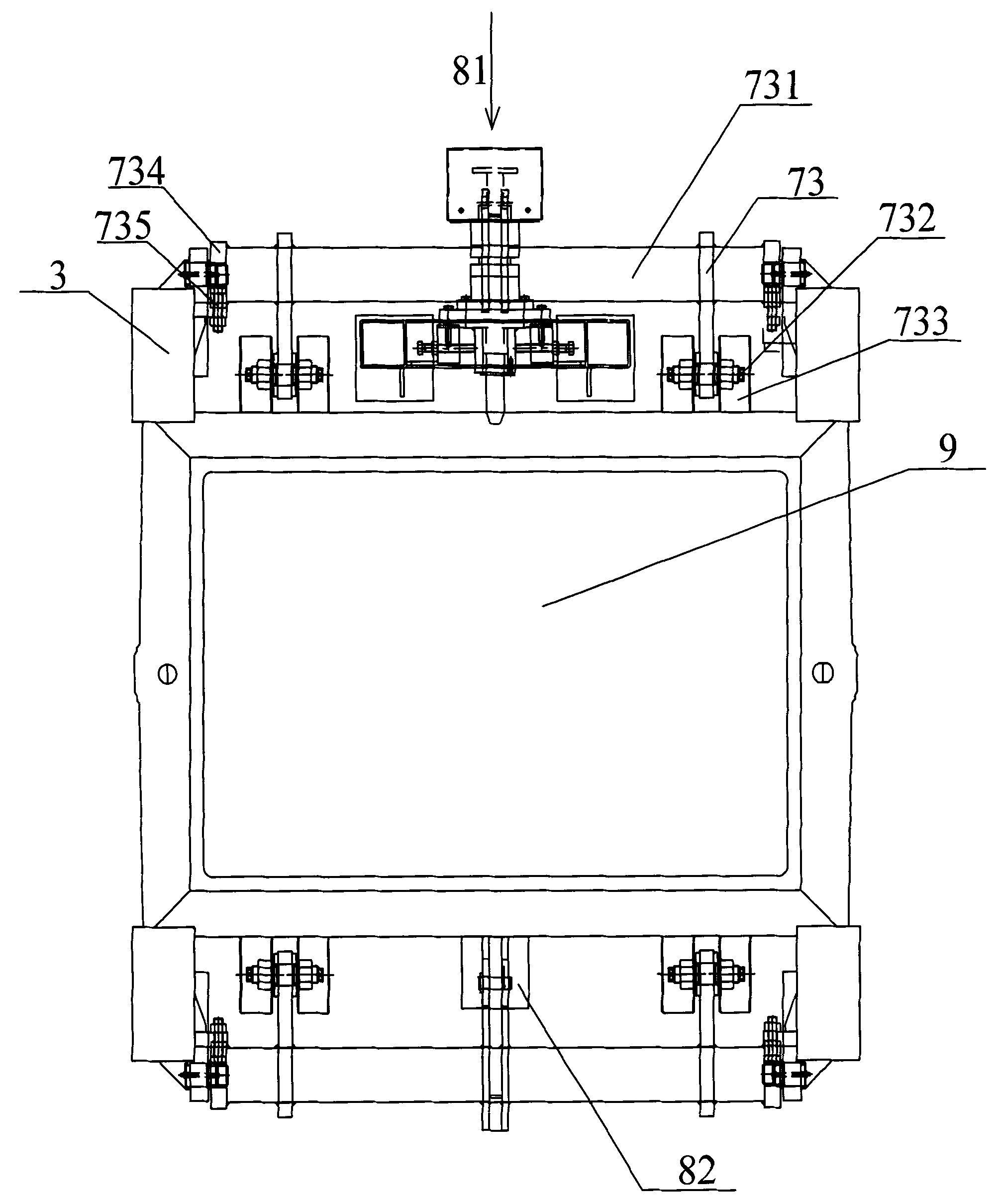

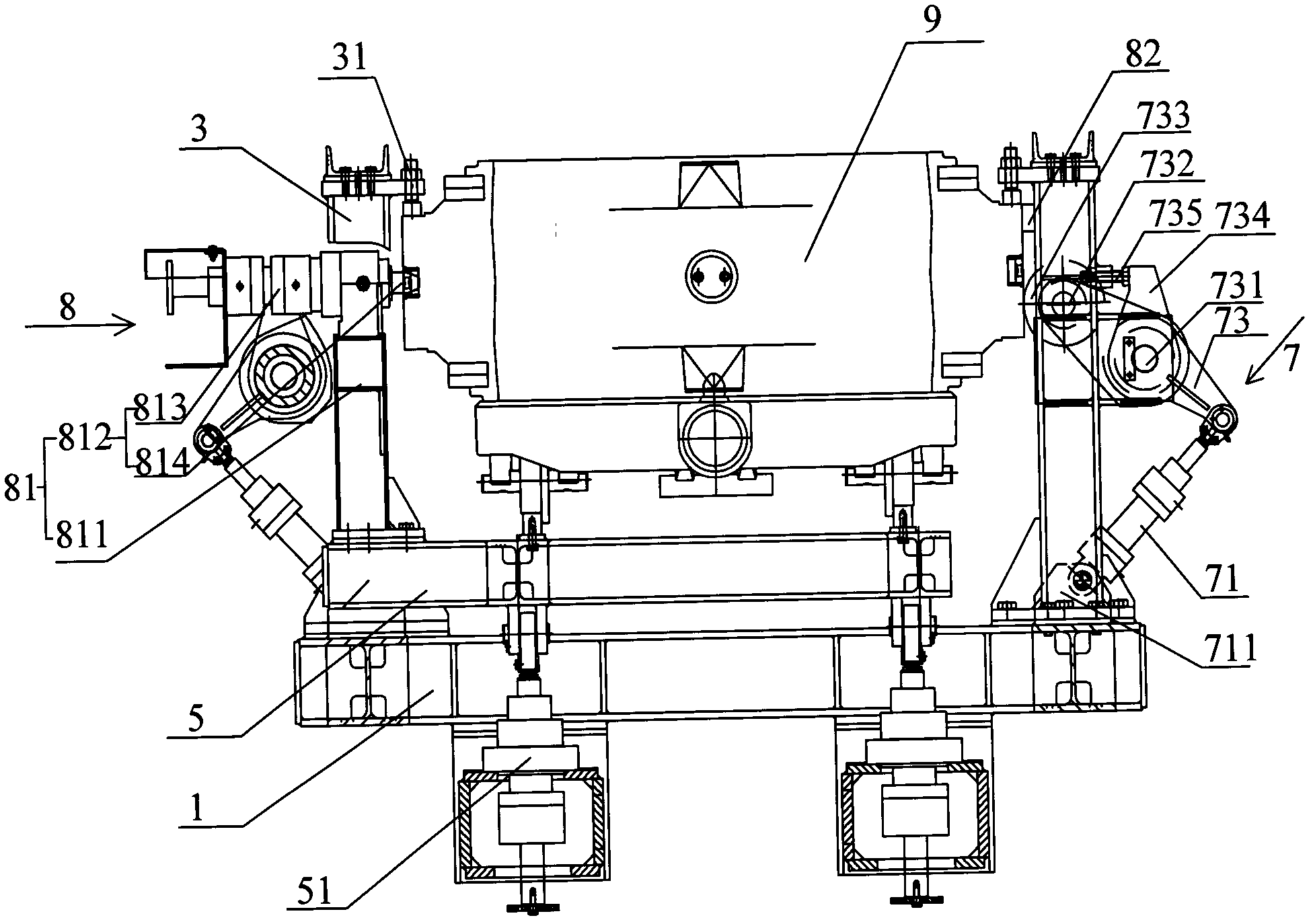

[0021] figure 1 , figure 2 and image 3 A preferred embodiment of the invention is shown (with figure 1 The left and right direction in is horizontal, perpendicular to figure 1 Orientation on paper is portrait). see figure 1 , the sand box positioning device includes: an underframe 1 and vertical stands 3 fixed on both lateral sides of the underframe 1, the underframe 1 is provided with a sand box push-up plate 5 and a pair of eccentric wheel lateral positioning components 7, and the sand box The box push-up plate 5 is connected with the first driving mechanism 51 (which may be a hydraulic cylinder), and has a positioning position and a leveling position for moving up and down (that is, figure 1 In the up and down d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com