Pull type clutch cover assembly assembling device and assembling method

A technology of assembly assembly and clutch cover, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, high labor intensity, and difficult to guarantee assembly quality, and achieve convenient and fast operation, reduce labor intensity, Good assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

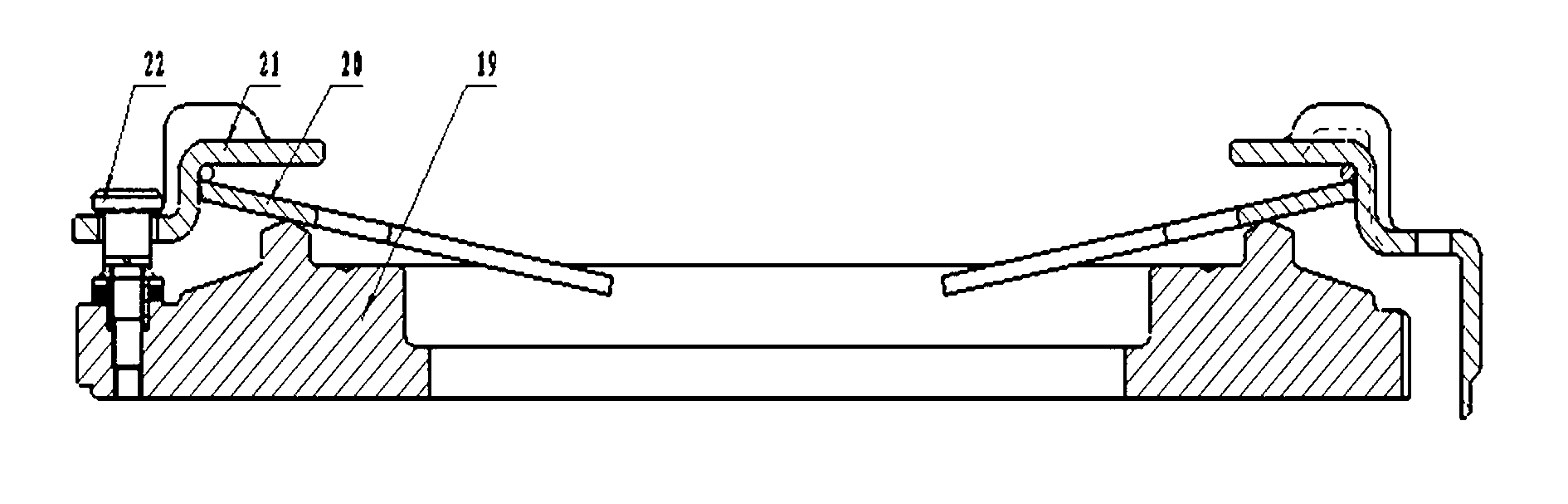

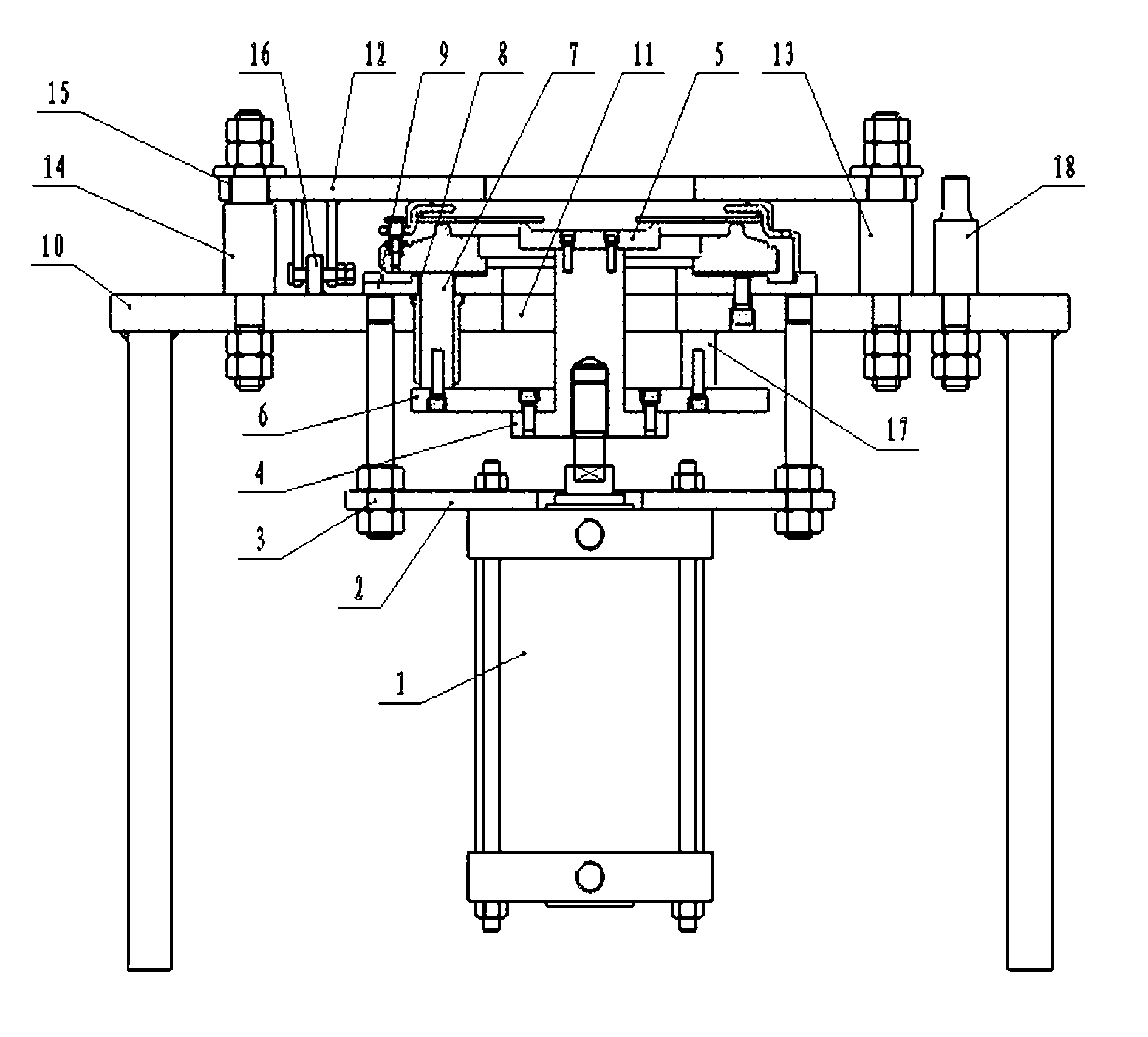

[0013] according to figure 2 The assembly device of the automobile pull clutch cover assembly shown is mainly composed of an operating table 10, a cylinder mechanism 1, a cylinder mounting plate 2, a column head flange 4, a transmission plate 6, a pressure plate ejector rod 7, and an upper pressure plate 12 and assembly template 9 and other components, the cylinder mounting plate 2 is set below the operating table 10, and a cylinder mechanism 1 is suspended vertically below the cylinder mounting plate 2, and the cylinder mounting plate 2 uses a double-ended screw 3 and the operating table 10 Connection, the pneumatic column head of the cylinder mechanism 1 is connected with the lower end of the column head flange 4 fixedly installed on the transmission plate 6, and the top plate 5 of the diaphragm spring 20 is fixed on the upper end of the column head flange 4 . In order to facilitate the assembly of the cover assembly components in the assembly device, an assembly template 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com