Method and device for manufacturing microbial compound fertilizers

A technology for compound fertilizers and manufacturing methods, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of excessive bacteria, low content of effective bacteria in products, backward technology, etc., achieve high bacterial activity and avoid microbial inactivation and death, prolonging the effect of fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 The microbial compound fertilizer manufacturing device of the present invention

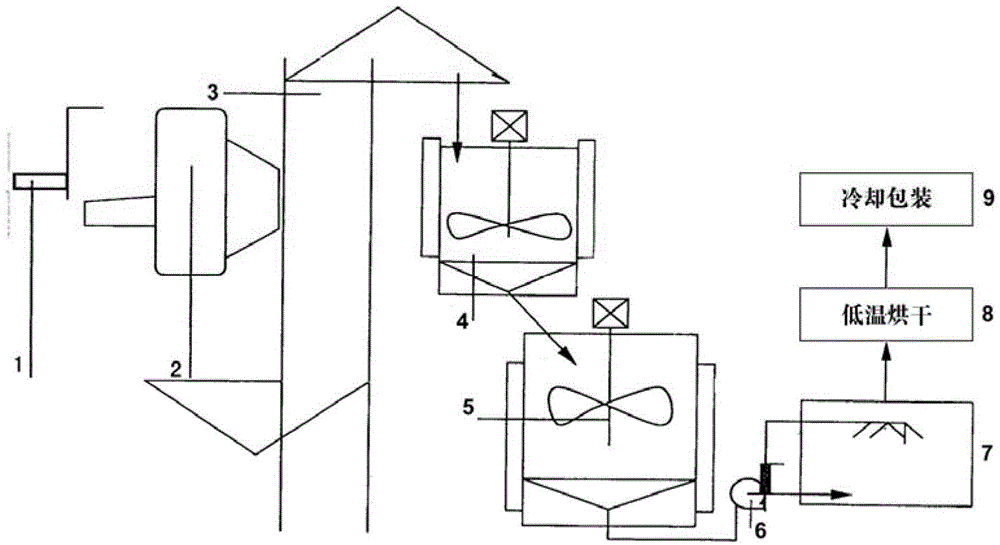

[0046] The device applied to the manufacture of microbial compound fertilizer consists of a compound granulation device and a pulping inoculation device (such as figure 1 Shown), the two are connected by a conveyor belt.

[0047] The pulping raw materials are weighed by the meter 1 and stirred evenly in the mixer 2, and the ingredients are sent to the pulping tank 4 of the pulping inoculation device with the bucket elevator 3 .

[0048]The slurry inoculation device is composed of a slurry tank 4, a slurry storage tank 5, a spray pump 6, a cylinder mixer 7, a low-temperature drying device 8 and a cooling system 9, and the slurry is discharged through the discharge valve at the bottom of the slurry tank 4. To the slurry storage tank 5, the bottom of the slurry storage tank 5 is connected to the spray pump 6, the nozzle of the spray pump 6 is in the upper part of the cylinder mi...

Embodiment 2

[0052] Embodiment 2 produces microbial compound fertilizer according to the method of the present invention

[0053] Bacillus licheniformis, Bacillus lateralosporus, Bacillus pumilus, Bacillus megaterium, and silicate bacteria were respectively cultured into spore powder, and the spore powder was mixed according to the proportion to obtain a compound bacterial agent. Add water to the pulping tank at a ratio of 1:5:100, so that the water content of the material mixture is 25-30%. Steam is introduced into the jacket of the outer wall of the pulping tank for heating, and the temperature in the pulping tank is controlled at 35-30%. At 40°C, stir the material with a stirrer to make a slurry; open the discharge valve at the bottom of the slurry tank, and put the prepared slurry into the slurry storage tank through the filter screen, and steam is also introduced into the jacket of the outer wall of the slurry storage tank for heating. Temperature, the temperature in the slurry storag...

Embodiment 3

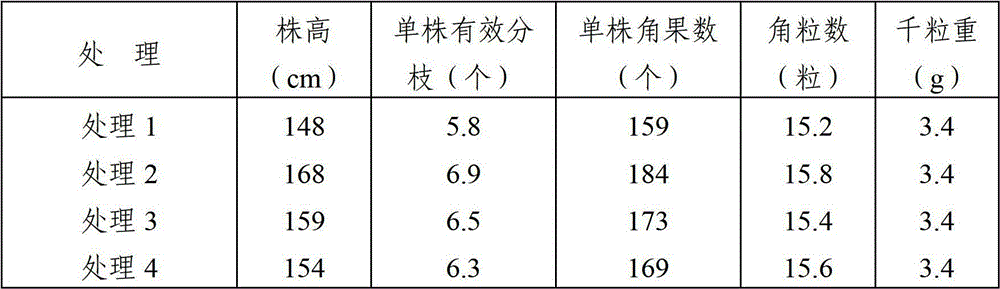

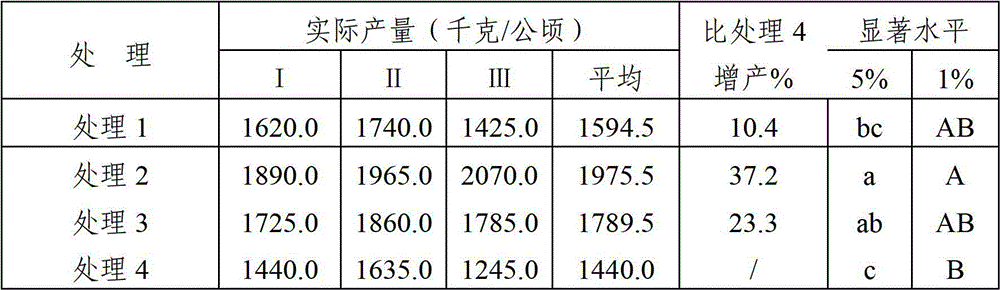

[0058] Embodiment 3 produces microbial compound fertilizer according to the method of the present invention

[0059] Bacillus licheniformis, Bacillus lateralosporus, Bacillus pumilus, Bacillus megaterium, and silicate bacteria were respectively cultured into spore powder, and the spore powder was mixed according to the proportion to obtain a compound bacterial agent. Add water to the pulping tank at a ratio of 1:5:100, so that the water content of the material mixture is 25-30%. Steam is introduced into the jacket of the outer wall of the pulping tank for heating, and the temperature in the pulping tank is controlled at 35-30%. At 40°C, stir the material with a stirrer to make a slurry; open the discharge valve at the bottom of the slurry tank, and put the prepared slurry into the slurry storage tank through the filter screen, and steam is also introduced into the jacket of the outer wall of the slurry storage tank for heating. Temperature, the temperature in the slurry storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com