Structure of putting brick of annealing electric furnace

A technology for laying bricks and electric furnaces, which is applied in the field of industrial heat treatment equipment, can solve the problems of easy falling off of electric furnace wires, unreasonable structure, and many joints of laying bricks, etc., so as to improve the overall thermal insulation effect, reduce the consumption of electric energy, and reduce the problem of joints. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

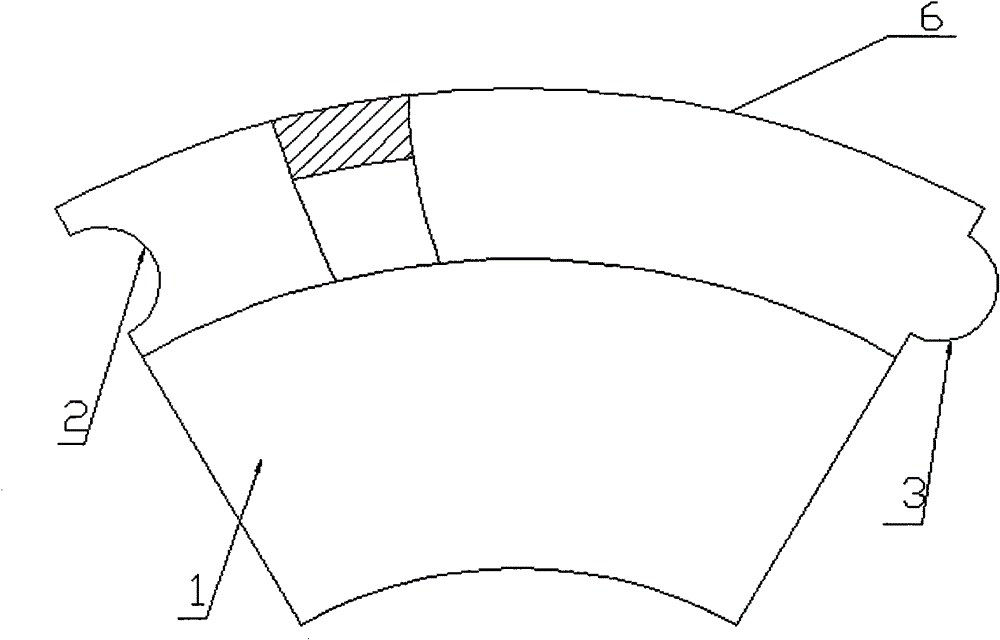

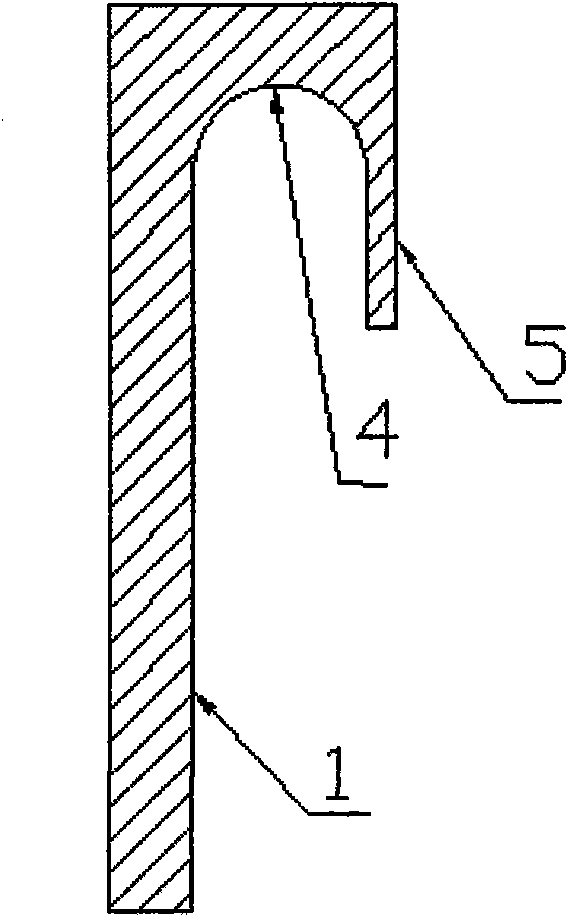

[0010] Make the included angle of 60° at the fan-shaped angle between the brick-resting body (6) and the brick-resting brick (1), and make two convex arc grooves (3) and concave arc grooves (2) respectively at the raised parts of the fan-shaped two sides. The groove should be able to be fastened with the groove on the adjacent brick. In the outer circle direction of the brick (1), make a flange (5) along the outer circle direction, and make an inward semicircle on the inner side of the flange (5). Groove (4), this is as the place for installing and fixing the electric furnace wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com