Method for braiding automobile fiber-braided antiskid net

A fiber weaving and anti-slip technology, applied in the field of weaving, can solve the problems of easy aging and breakage, poor anti-skid effect, and poor use effect, and achieve low cost, increased grip and ice-breaking ability, and low rolling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

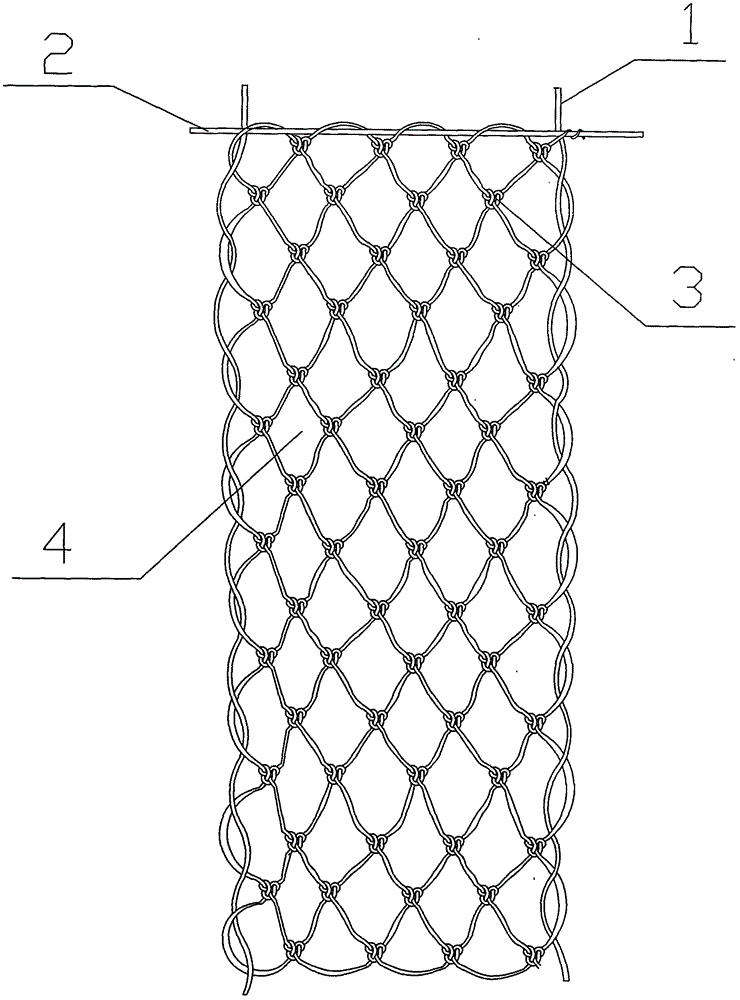

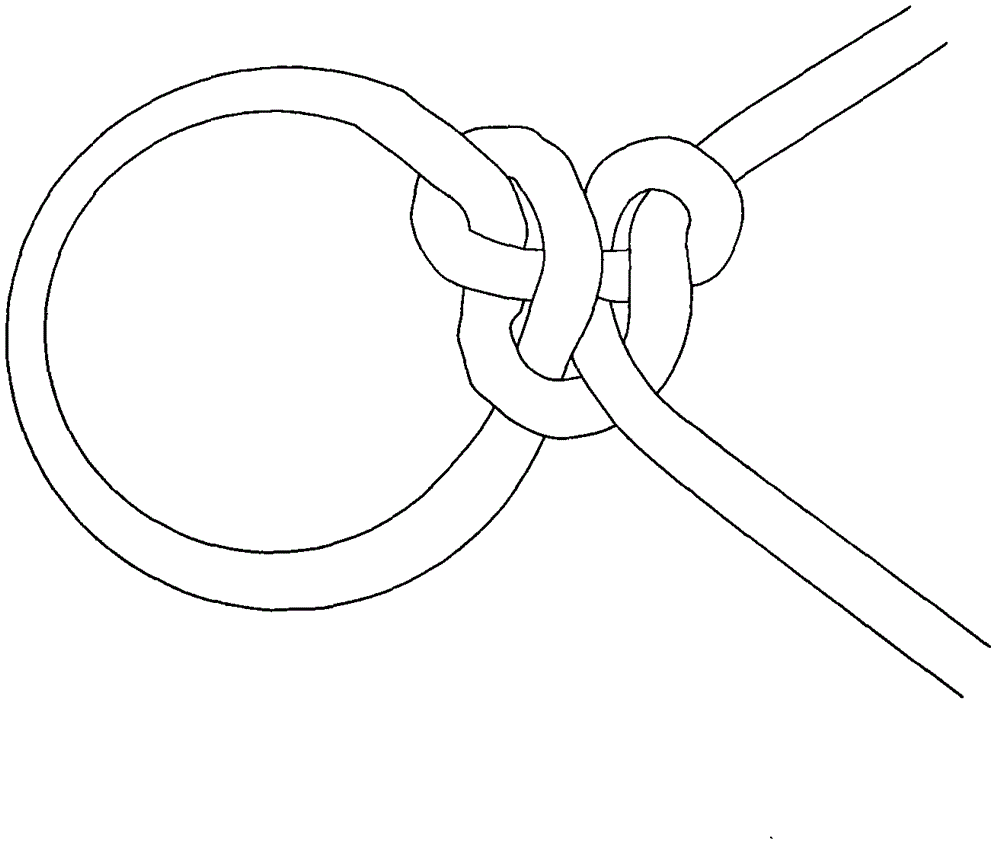

[0027] Such as figure 1 Shown: an automobile fiber woven anti-slip net, including fiber rope woven net 4, fixed rod 2, side fixed elastic band 1, double-sided double-sided symmetrical multi-bump ingot knot 3, said fixed rod 2 is used to cover The first end of the fiber rope serves to fix the woven net, and the side fixing elastic bands 1 are sheathed on both sides of the fiber woven net to automatically adjust the overall tightness of the anti-skid net during installation and use.

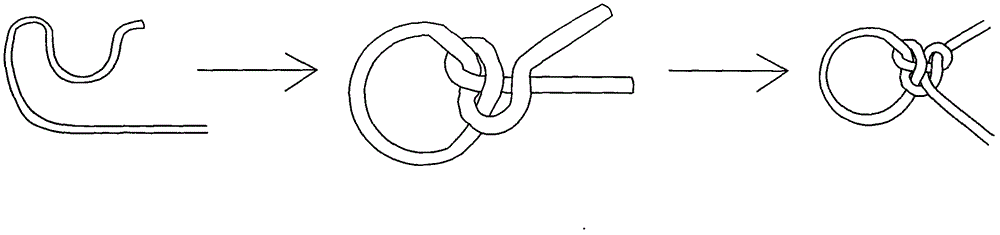

[0028] The present invention also relates to a weaving method of automobile fiber woven anti-skid net, the steps of which are: Figure 4 As shown, one end of the fiber rope is fixed to one end of the fixed rod, and then the fiber rope is wound on the fixed rod. The number of turns is set according to the width of the designed anti-skid net, and the size of the mesh required for different types of tires To set the reserved length of the loop; the mesh structure will be woven through the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com