Construction method adopting inverted triangular obliquely-crawling hanging basket

A construction method and inclined climbing technology, applied in the engineering field, can solve the problems of complex structure, poor walking stability, and difficulty in assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

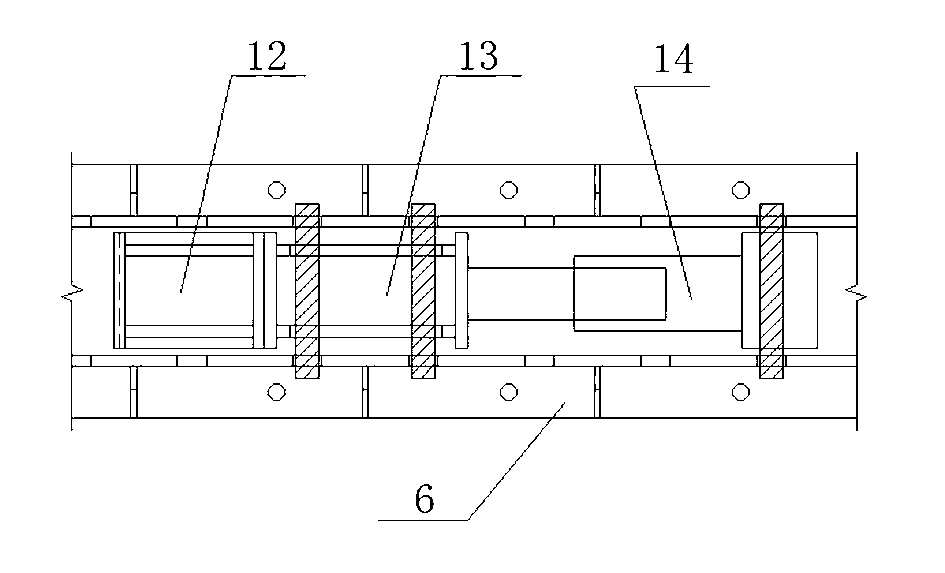

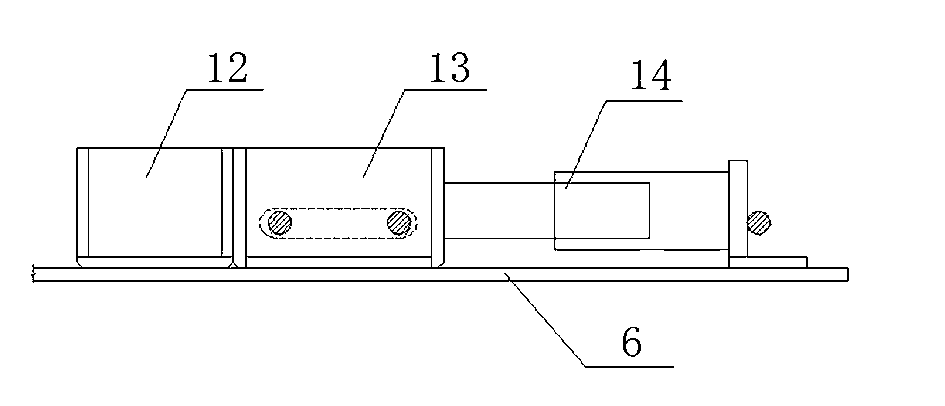

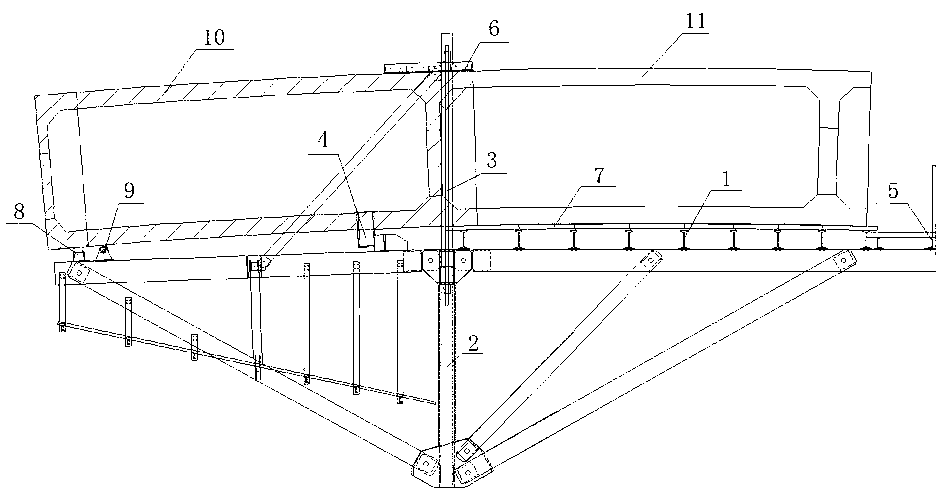

[0031] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, features and effects of the construction method of the upside-down triangular inclined climbing hanging basket proposed according to the present invention will be described in detail as follows.

[0032] see Figure 1 to Figure 3 , the construction method of the upside-down triangular inclined climbing hanging basket of the present invention, comprises the following steps:

[0033] (1) The concrete strength of the bridge under construction meets the design requirements;

[0034] (2) Install a jack or hoist on the beam surface of the cast box girder 10 whose strength meets the requirements to lift the assembled bottom basket frame 1 and part of the beam of the main truss system 2 to the bottom of the cast box girder 10, and install the tie rod 3 and the anti-retreat anti-shear arm 4, the anti-retreat anti-shear arm 4 is manually installed with the assistance of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com