Holder for sensor installation

A retainer and sensor technology, which is applied in the direction of instruments, transportation and packaging, and vehicle safety arrangements, can solve the problems of poor aesthetics, offset between the retainer and the bumper hole, and the reduction of sensor detection accuracy, so as to suppress the increase , The effect of reducing the number of parts and improving the installation operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

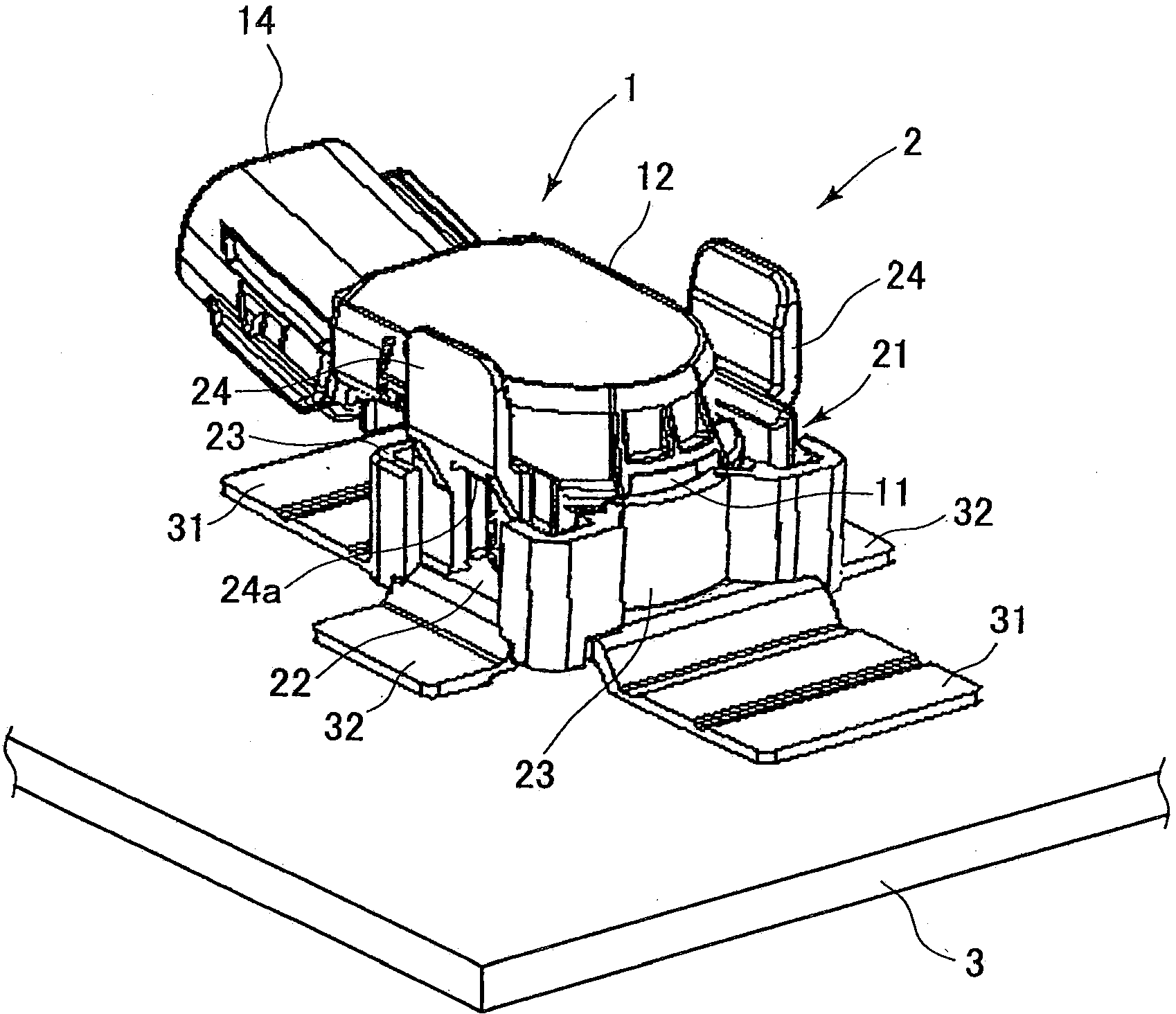

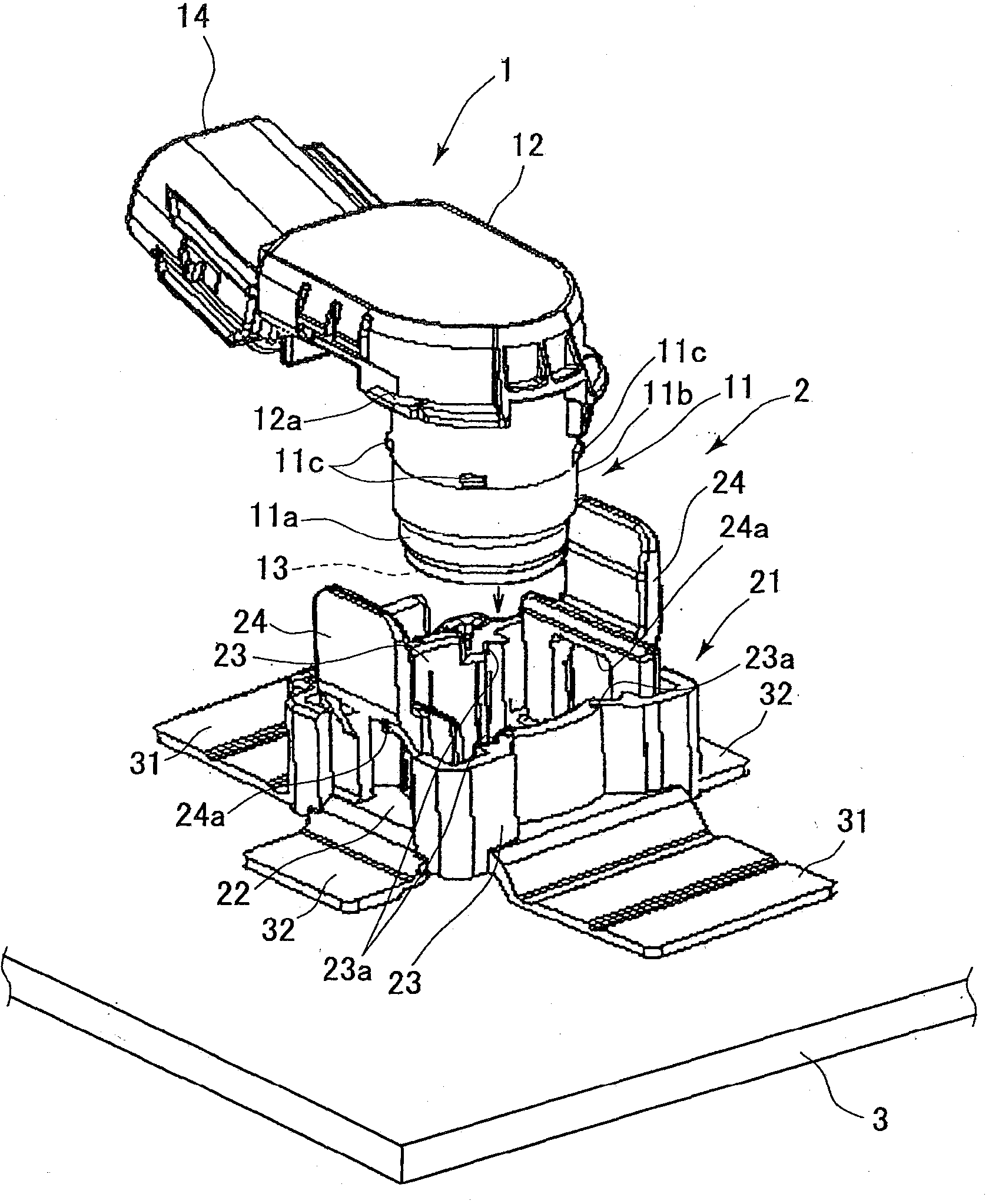

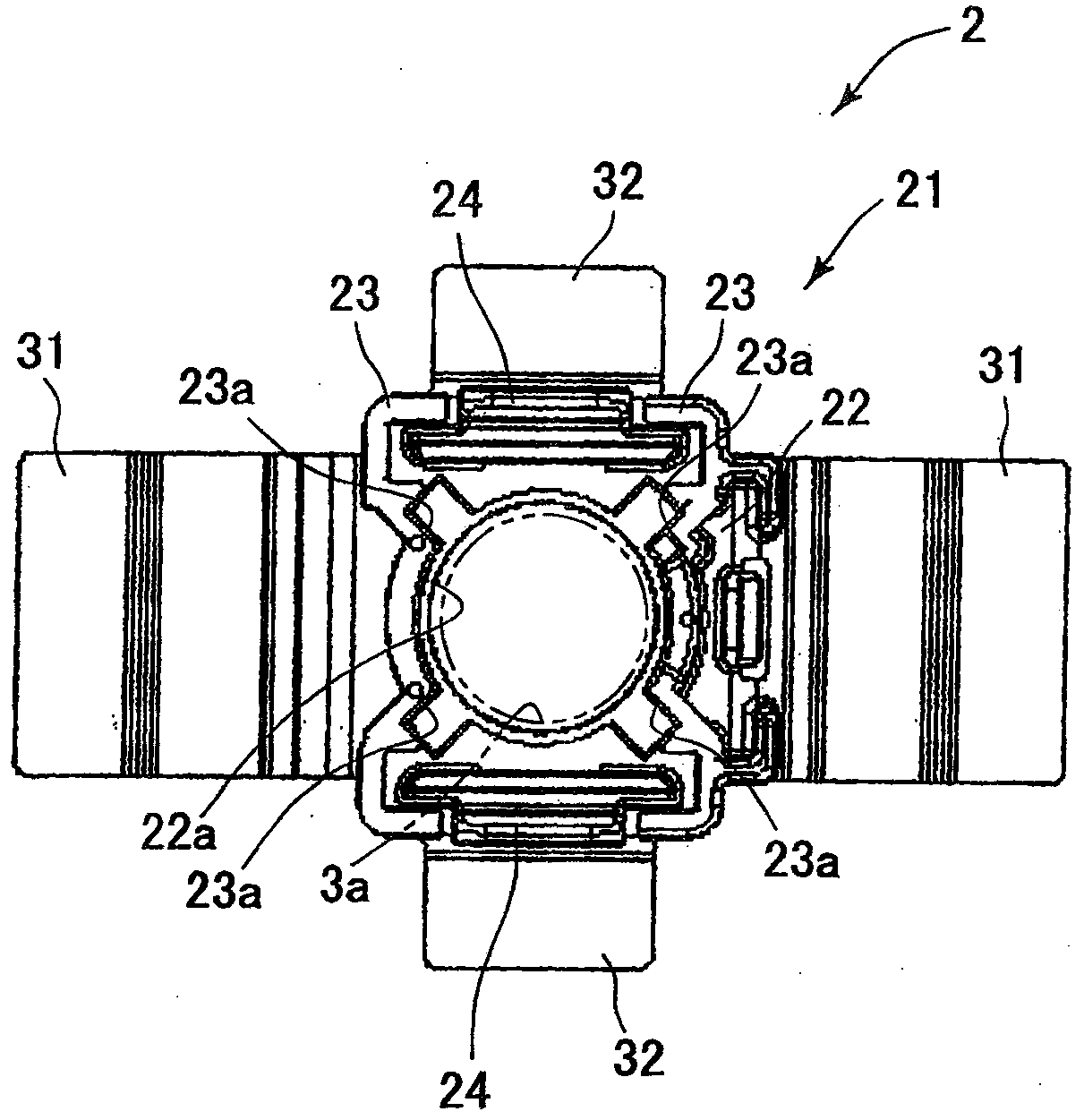

[0053] figure 1 It is a perspective view showing the state where the ultrasonic sensor 1 (hereinafter referred to as the sensor 1 ) is attached to the bumper 3 via the sensor attachment holder 2 (hereinafter referred to as the holder 2 ) according to the first embodiment, figure 2 is a perspective view showing two components before the sensor 1 is mounted on the holder 2 .

[0054] The sensor 1 is a transmitter-receiver type sensor that vibrates a piezoelectric ceramic vibrator by, for example, a piezoelectric effect to emit ultrasonic waves and converts the vibration of the ultrasonic waves incident on the piezoelectric ceramic vibrator into electrical signals, and includes a sensor main body 11, a housing Section 12 et al.

[0055] The sensor main body 11 is formed in a stepped cylindrical shape, and the diameter of the tip portion 11 a (lower end portion) is the smallest. A microphone 13 (detection unit) having a built-in piezoelectric ceramic vibrator is incorporated in...

Embodiment 2

[0087] In the above-mentioned Embodiment 1, the center positioning member 4 and the retainer 2 are made into separate parts in advance, but instead of this structure, for example, Figure 10~Figure 18 As shown, the holder 120 with a centering function may also be formed in which the centering member 140 is integrally formed.

[0088] Such as Figure 15 and Figure 16 As shown, the center positioning member 140 is configured to include: a cylindrical mandrel part 141 ; and a plurality of ribs 142 and spring parts 143 formed on the outer peripheral surface of the mandrel part 141 .

[0089] The core rod portion 141 is formed in a cylindrical shape. The ribs 142 are radially formed at equal angles in the circumferential direction of the core rod part 141 , and are integrally formed on the side surface of the core rod part 141 along the direction of the central axis. In this second embodiment, an example is shown in which three ribs 142 are provided at intervals of 120° in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap