Collecting tank of a heat exchanger

A technology for heat exchangers and heat exchanger tubes, applied in the field of collection tanks, can solve the problems of uneven contact between the bottom and the heat exchanger tubes, a large number of heat exchangers, and a large installation space, and achieve cost-effective manufacturing and more installation space. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

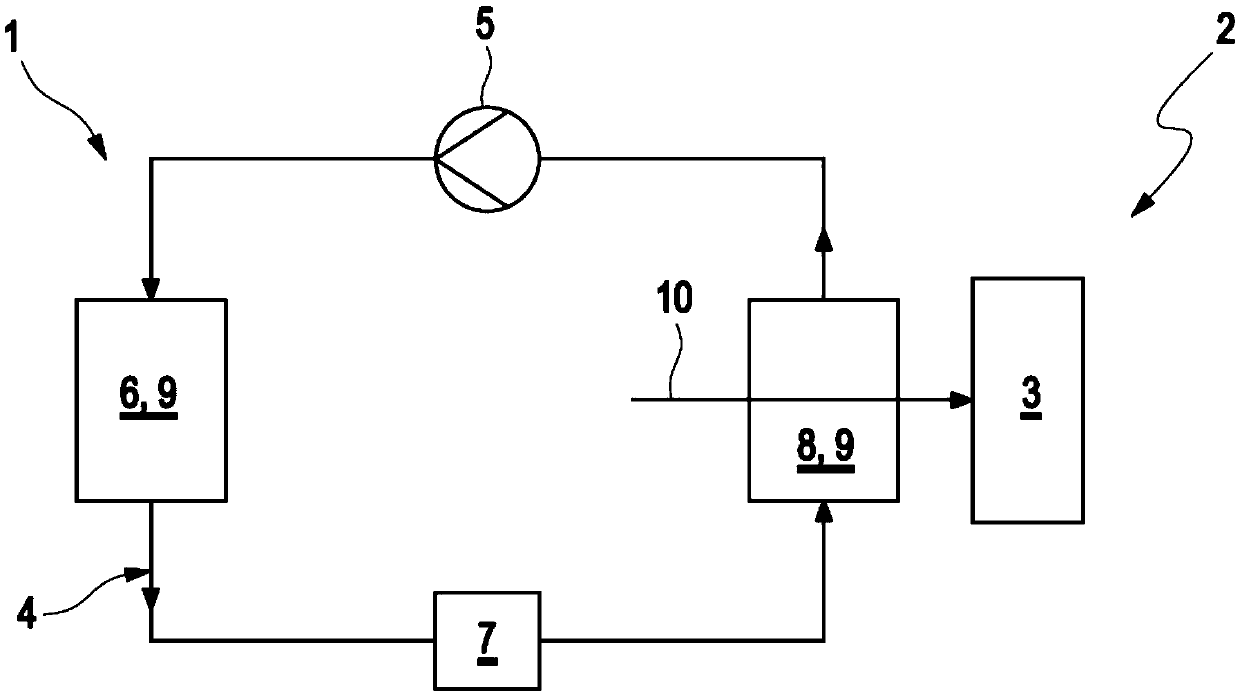

[0039] exist figure 1 An air-conditioning system 1 that can be used in a vehicle 2 for, for example, climate-conditioning a vehicle interior 3 of the vehicle 2 is illustrated in a highly simplified manner. The air conditioning system 1 has a circuit 4 in which a coolant is driven and circulated by a conveying device 5 . The coolant thus flows successively through the capacitor 6 , the expander 7 and the evaporator 8 , wherein the capacitor 6 and the evaporator 8 serve in each case as a heat exchanger 9 . The coolant and the further fluid flow through the corresponding heat exchanger 9 in such a way that heat exchange takes place between the coolant and the further fluid. In the case of the evaporator 8 , the further fluid is air 10 , which flows through the evaporator 8 and is thereby cooled, wherein the cooled air 10 is supplied to the vehicle interior 3 .

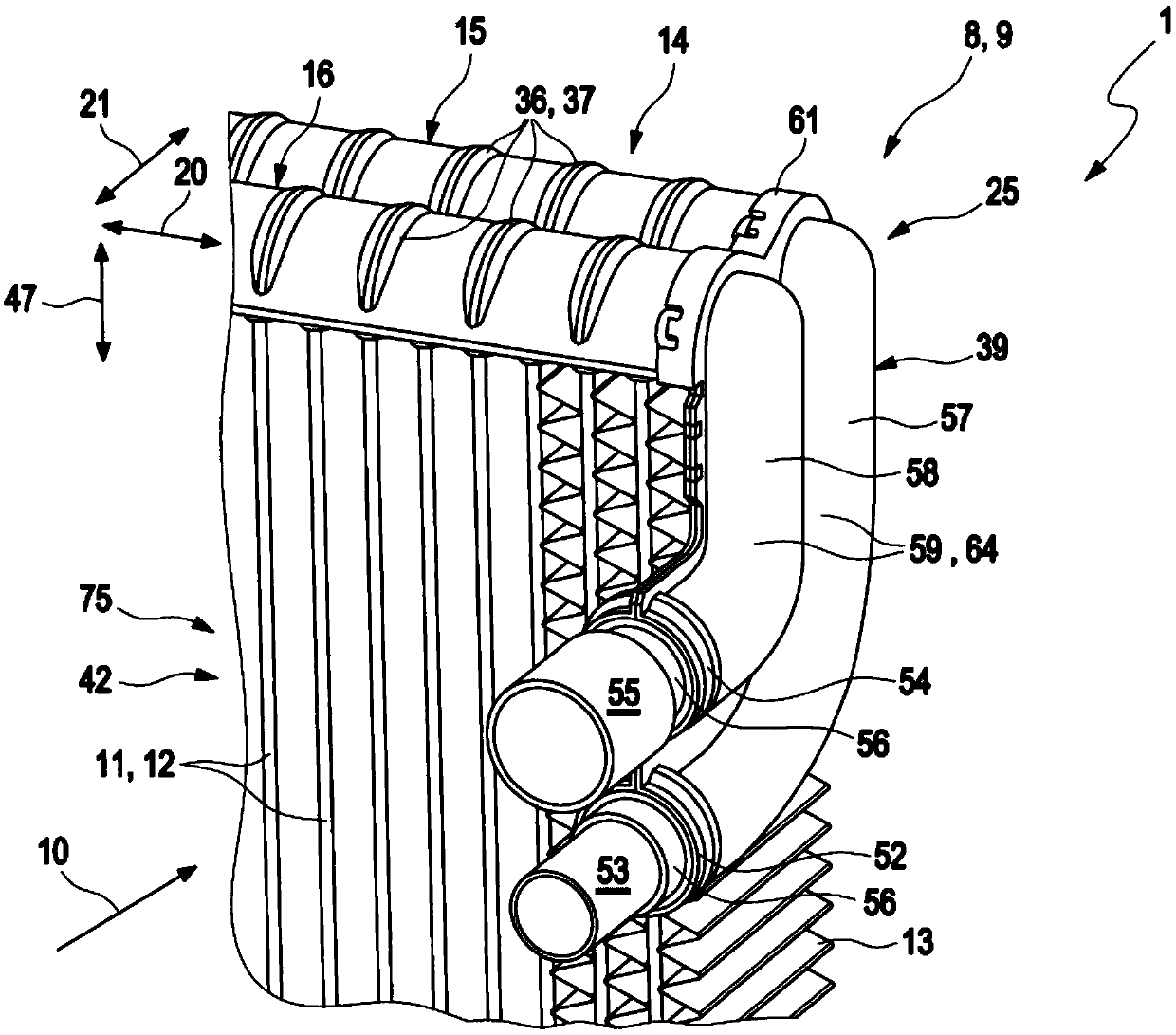

[0040] figure 2 An isometric partial view of a heat exchanger 9, in particular an evaporator 8, is shown. The heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com