Viscoelastic surfactants and methods of making and using same

A technology of surfactants and mixtures, used in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve problems such as large quantities of materials, difficulty in removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

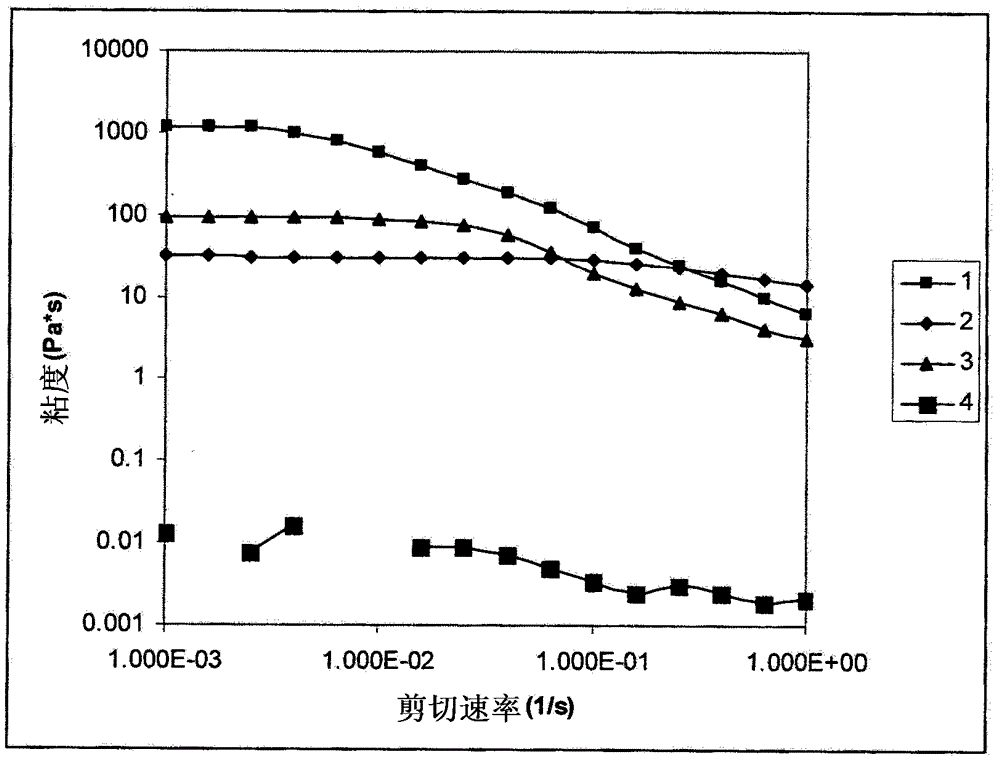

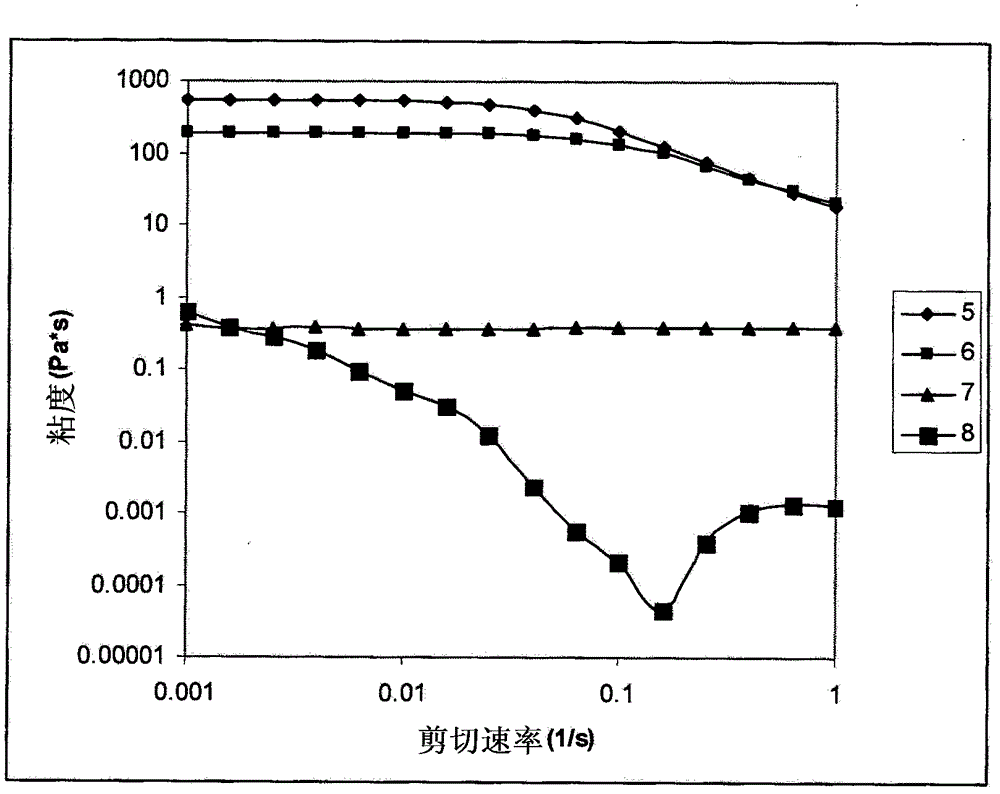

[0050] The rheological properties of CASP-VC of the type described herein were investigated. Eight samples were prepared, designated Samples 1-8. Sodium oleate (NaOle), commercially available from TCI, USA, was used as the anionic surfactant and octyltrimethylammonium chloride (C 8 TAC) was used as the cationic surfactant to prepare samples 1-4. use C 8 Samples 1-4 were prepared at ratios of TAC:NaO of 3:7, 4:6, 2:8, and 1:9, respectively. A sufficient amount of the sample was then dissolved in deionized water (DI H 2 O) to form a 3wt.% solution. The resulting CASP-VC was anion-rich due to the larger anion-to-cation ratios of samples 1-4.

[0051] Sodium caprylate (NaCap) commercially available from TCI USA was used as anionic surfactant and octadecyltrimethylammonium chloride (C 18 TAC) was used as the cationic surfactant to prepare samples 5-8. Samples 5-8 were prepared using C18TAC:NaCap ratios of 7:3, 6:4, 8:2, and 9:1, respectively. Sufficient amounts of these sam...

Embodiment 2

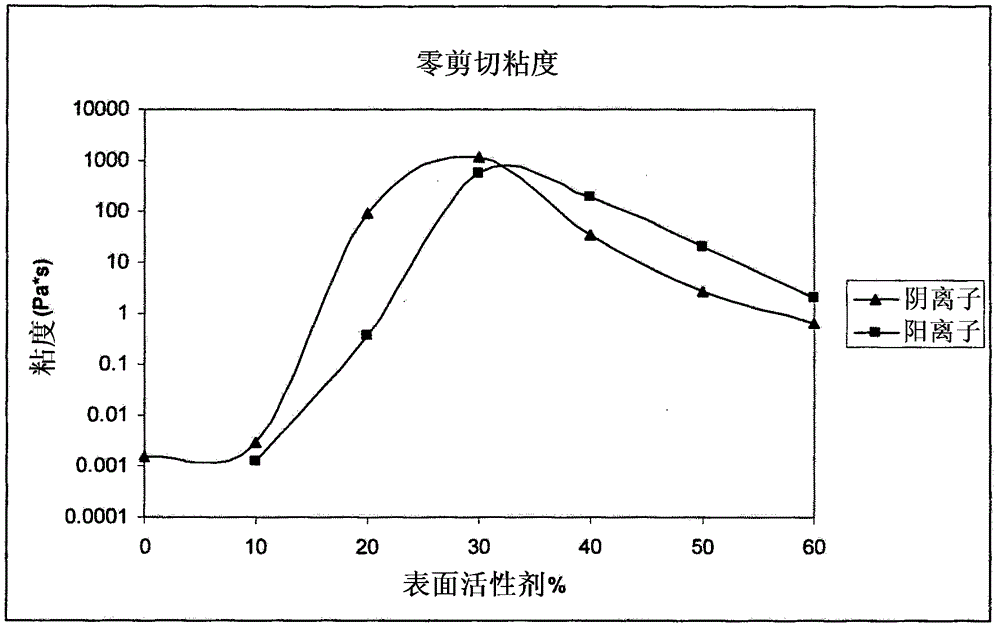

[0057] The zero-shear viscosity of anion-rich and cation-rich CASP-VC was studied. Samples 1-8 described in Example 1 were used again in this example. In addition, five more samples were prepared according to the description in Example 1, named samples 9-13. Table 2 shows the cationic and anionic surfactants and CAR for samples 9-13.

[0058] Table 2

[0059] sample

[0060] image 3 is a graph of the viscosity of samples 1-13 as a function of the weight fraction of the minor component. For samples 1-4 and 9-11, the subcomponent was cationic surfactant. For samples 5-8 and 12-13, the subcomponent was anionic surfactant. The results showed that the CARs that produced the greatest viscosity were about 70:30 and 30:70, as image 3 The peaks on the anion-rich and cation-rich CASP-VC are shown. Additionally, the viscoelasticity of both cation-rich and anion-rich CASP-VC exhibited up to a 300,000-fold increase compared to the surfactant component alone. This increa...

Embodiment 3

[0062] The kinetic properties of CASP-VC of the type described herein were investigated. Specifically, samples 1-3 and 5-7 in Example 1 were measured for complex viscosity, storage modulus, and loss modulus as a function of frequency. Figure 4 and 5 Graphs of complex viscosity, storage modulus, and loss modulus as a function of frequency for samples 1-3 and samples 5-7, respectively. It was shown that these fluids exhibited significant loss and storage moduli, demonstrating their viscoelastic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com