Paper cutting device capable of automatically adjusting tension and automatically guiding paper

A paper cutting device and self-tuning technology, applied in the direction of metal processing, etc., can solve the problems of not being able to meet the needs of modern scale production and increasing customer demand, affecting work efficiency, and affecting production quality, so as to facilitate popularization and use, improve production quality, Effects that are easy to standardize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

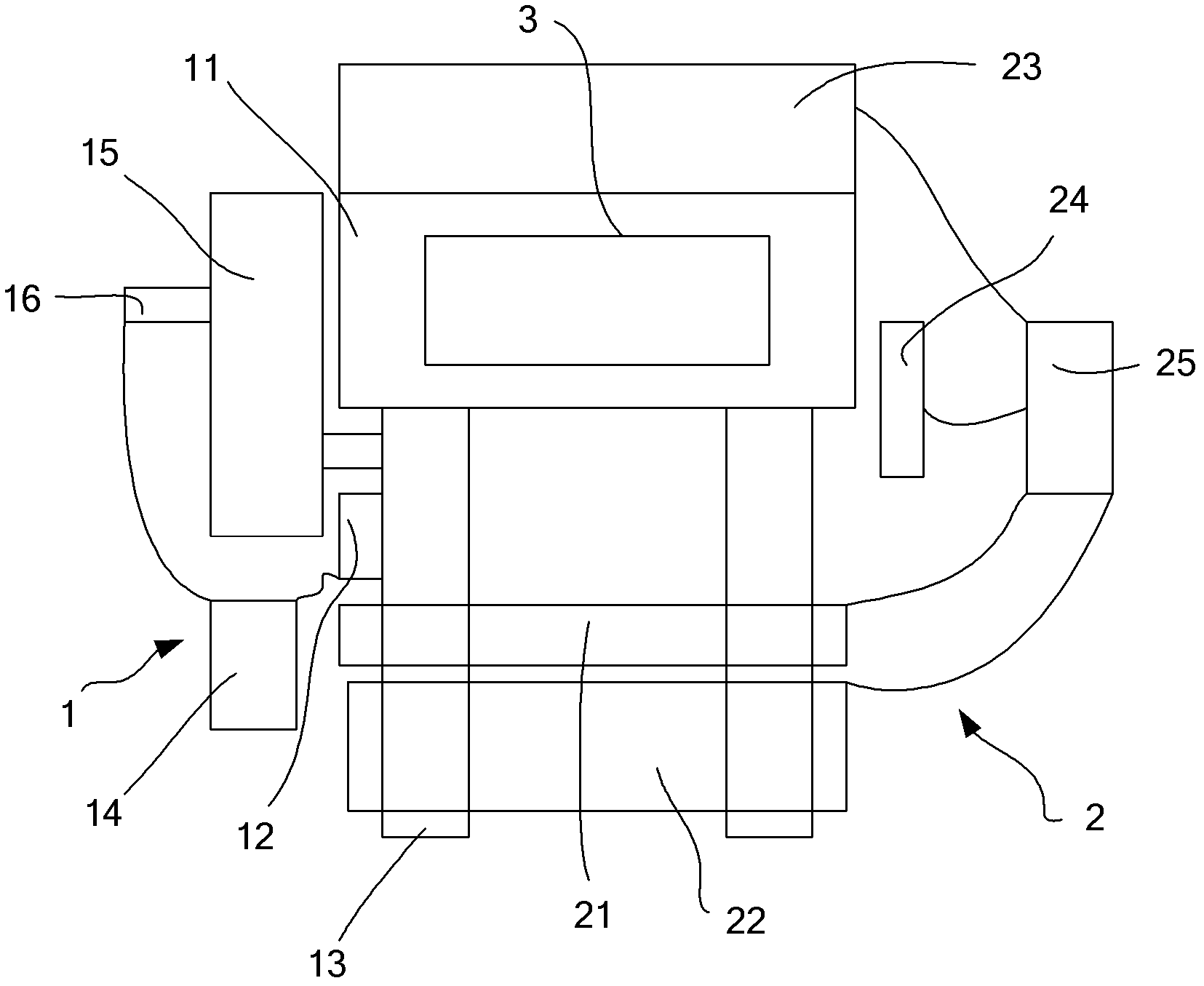

[0021] Such as figure 1 As shown, the present invention includes a paper threading structure 1 and a paper cutting structure 2 . The paper threading structure 1 is used for pulling the paper roll 3 to extend, and the paper cutting structure 2 is used for cutting, switching and sticking the paper roll.

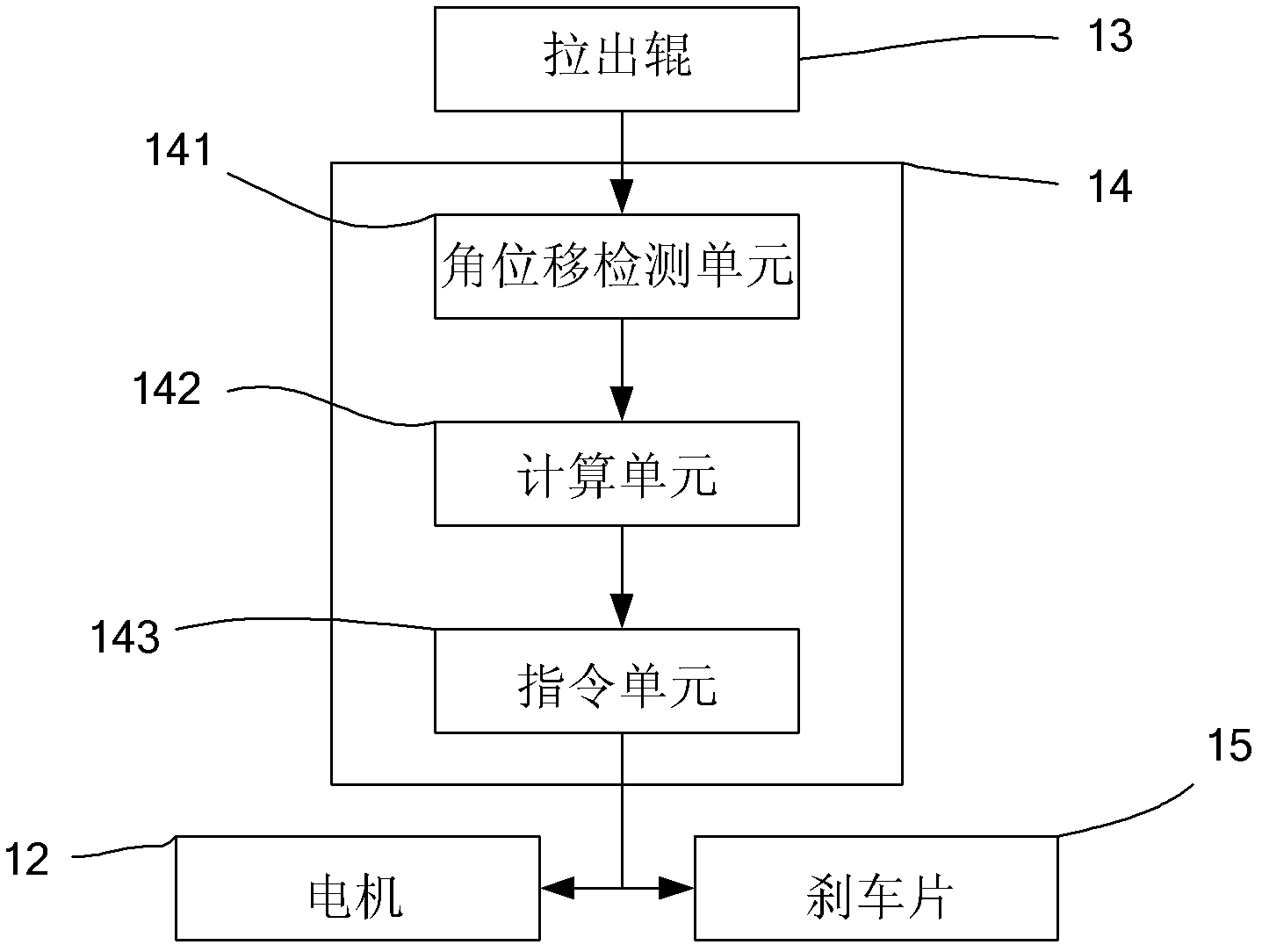

[0022] The paper threading structure 1 includes a paper stocker 11 , a motor 12 and a pull-out roller 13 , and paper rolls 3 are stored in the paper stocker 11 . The motor 12 drives the pull-out roller 13 to rotate, and the pull-out roller 13 pulls the paper roll 3 to unfold. The paper threading structure 1 is also provided with an automatic controller 14 for self-adjustment of the traction tension of the paper roll 3 .

[0023] The paper cutting structure 2 includes a cutter 21 for cutting off the traction paper surface, a pressure roller 22 for sticking the paper surface, and a paper loader 23 . The paper cutting structure 2 also includes a monitor 24 for monitoring the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com