Trace lubricating oil for machining steel hub and preparation method thereof

A technology of micro-lubricant and wheel hub, which is applied in the field of micro-lubricant for steel wheel hub processing and its preparation, can solve the problems of high consumption of cutting fluid, rust, etc., and achieve the goals of saving usage, good lubricity, and good rust resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

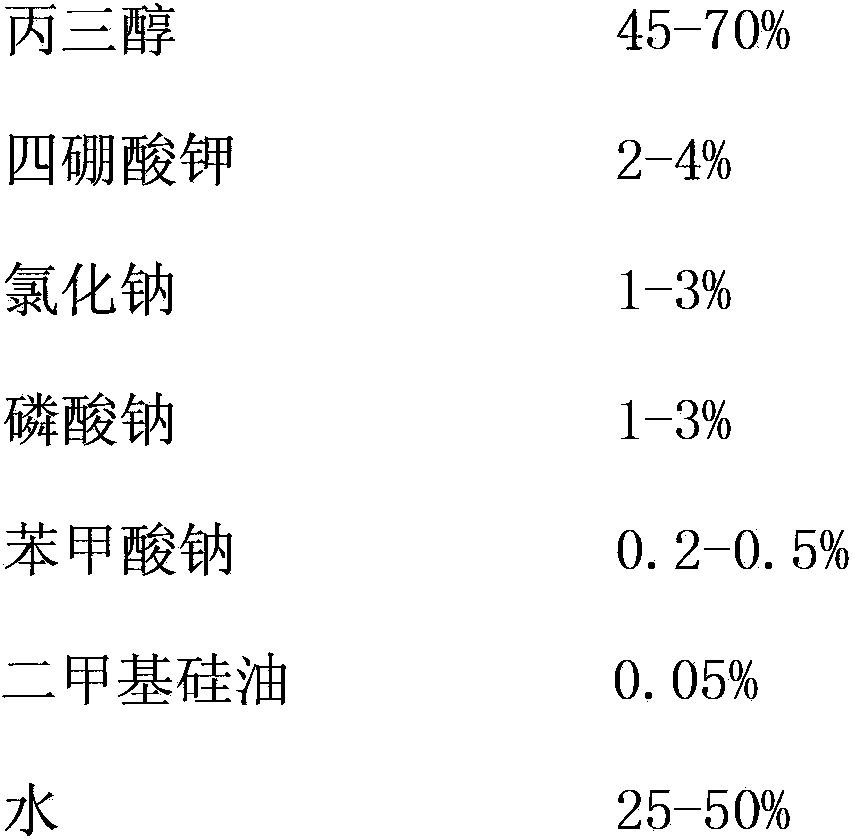

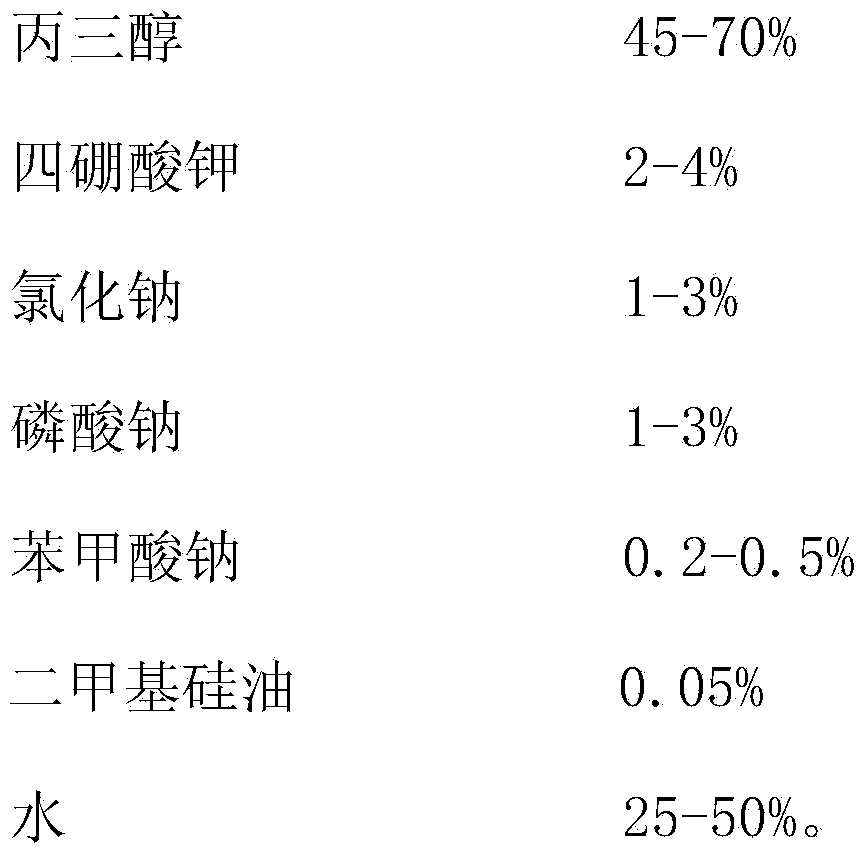

[0019] Add 45kg of glycerol, 2.6kg of potassium tetraborate, 1kg of sodium chloride, 1kg of sodium phosphate, 0.35kg of sodium benzoate, and 0.05kg of simethicone into 50kg of water and mix and stir for 60 About minutes, take a sample and observe until it is completely transparent and ready-to-use packaging.

Embodiment 2

[0021] Add 48kg of glycerol, 2.75kg of potassium tetraborate, 1.5kg of sodium chloride, 1.5kg of sodium phosphate, 0.2kg of sodium benzoate, and 0.05kg of simethicone into 46kg of water and mix Stir for about 60 minutes, take a sample and observe until it is completely transparent and ready to use.

Embodiment 3

[0023] The glycerol of 55kg, the potassium tetraborate of 2kg, the sodium chloride of 3kg, the sodium phosphate of 1.55kg, the sodium benzoate of 0.4kg, the simethicone oil of 0.05kg, add successively the 38kg water that takes by weighing and mix and stir for 60 About minutes, take a sample and observe until it is completely transparent and ready-to-use packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com