Upper cam mechanism of computerized flat knitting machine

A computerized flat knitting machine and needle groove technology, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of large vibration, stitch damage, and single needle protection structure on the needle selection, so as to prolong the service life and reduce the Effect of vibration amplitude and unplanned displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

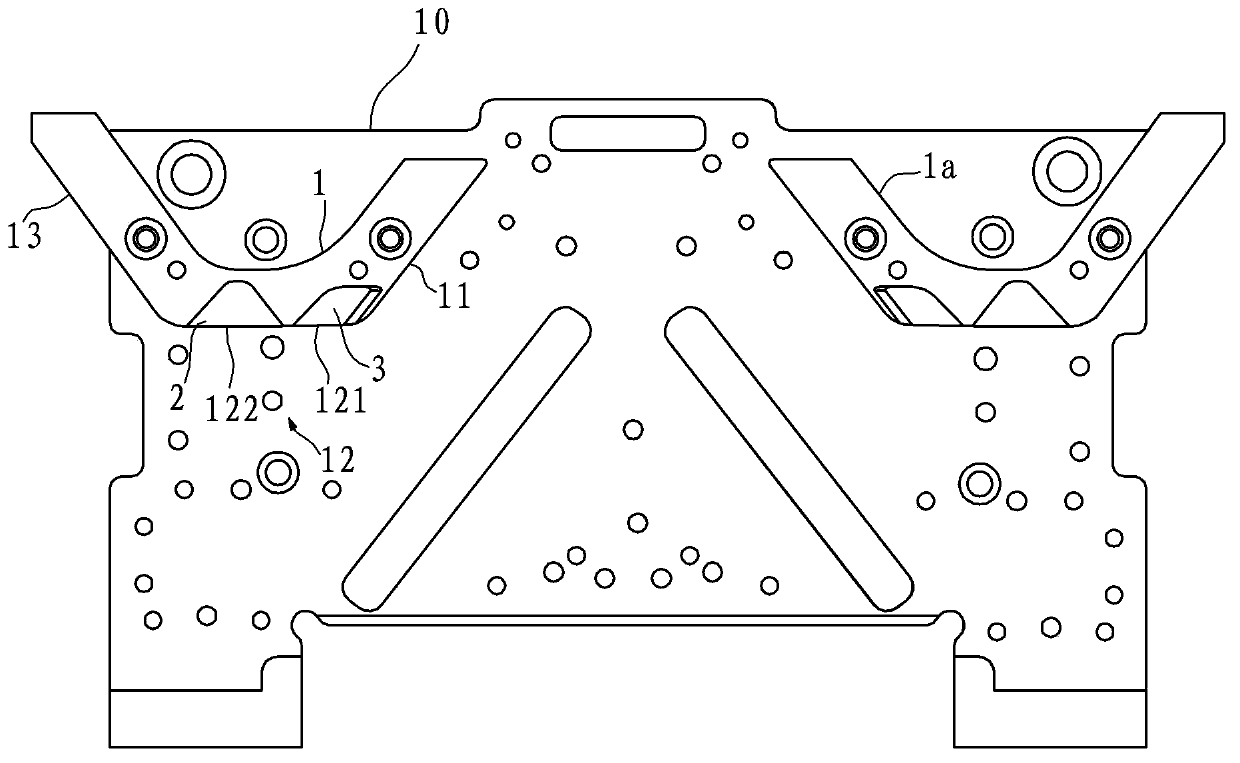

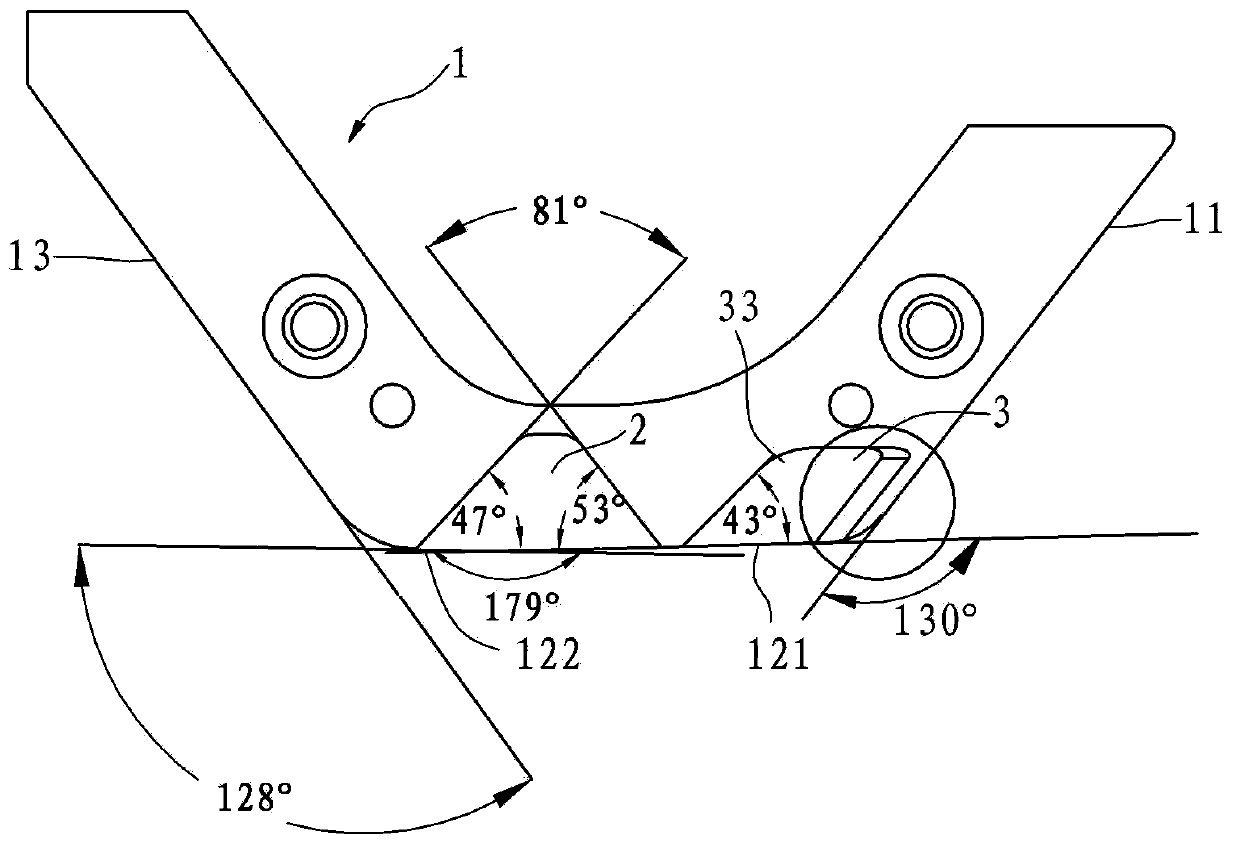

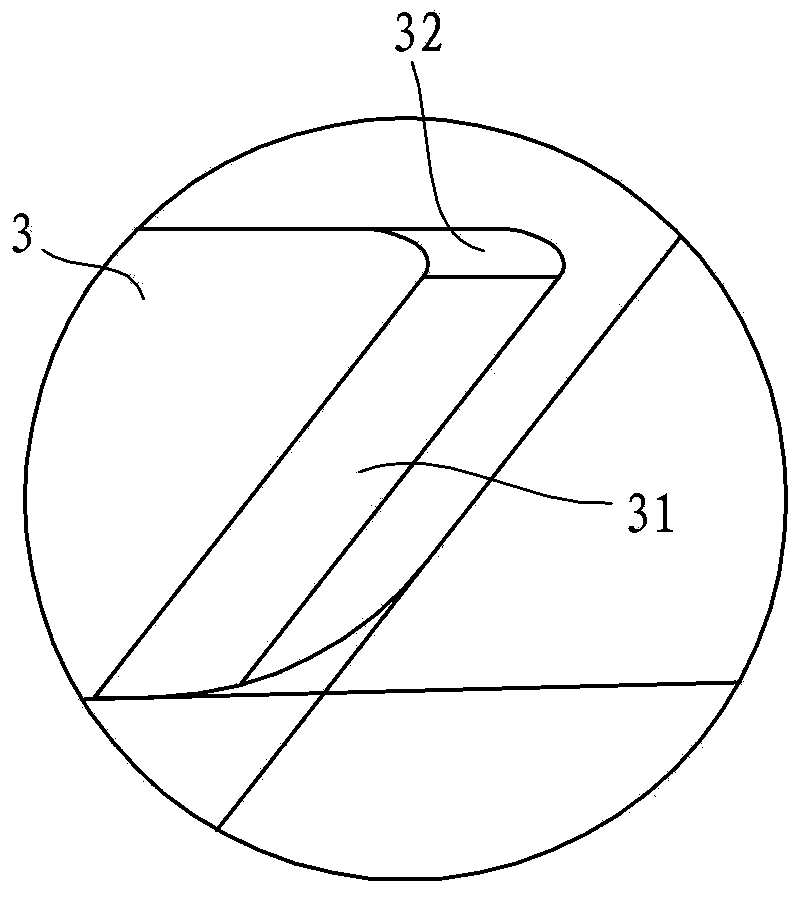

[0024] Example 1, such as figure 1 and figure 2 As shown, the upper guard mechanism in this embodiment is used in a single system, specifically, it includes a motherboard 10 and an upper left guard 1 and an upper right guard 1a arranged side by side on the motherboard 10 at intervals, an upper left guard 1 and an upper left guard 1a. The upper right bezel 1a is mirror-symmetrical with the central axis of the motherboard 10 as the symmetry line, and the upper left bezel 1 and the upper right bezel 1a are mirror-symmetric pieces. The upper left guard hill 1 includes the first section of needle surface 11, the second section of needle surface 12 and the third section of needle surface 13 in sequence, the first section of needle surface 11 and the third section of needle surface 13 are connected with the second section of needle surface. The needle surfaces 12 are connected by circular arc transitions, and the first section of the needle surface 11 and the third section of the n...

Embodiment 2

[0027] Example 2, such as Figure 4 and Figure 5 As shown, the upper guard mechanism in this embodiment is used in a dual system, specifically, the upper left guard 1, the middle upper guard 4, the upper right guard 1a, and the upper left guard 1 are arranged side by side on the motherboard 10 at intervals. It is mirror-symmetrical with the upper right guard mountain 1a taking the central axis of the motherboard 10 as the line of symmetry.

[0028] The middle and upper mountain guard 4 is located between the upper left guard hill 1 and the upper right guard hill 1a. The middle and upper hill guard 4 is a left-right symmetrical piece with the center line as the axis of symmetry. The second-level movement surface 42 and the third-level movement surface 43, the first-level movement surface 41, the third-level movement surface 43 and the second-level movement surface 42 are all arc transition connections, and the first-level movement surface 41 and The third-level needle surfac...

Embodiment 3

[0032] Example 3, such as Figure 6 As shown, the upper guard mechanism in this embodiment is used in the three systems, and two middle and upper guard hills 4 are arranged between the left upper guard 1 and the right upper guard 1a. Refer to Example 2 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com