Rapidly assembled steel footbridge in truss string structure

A string truss and assembled technology, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large steel consumption, low safety factor, and slow assembly speed, so as to achieve light weight, reasonable structure, easy assembly and The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to specific embodiments.

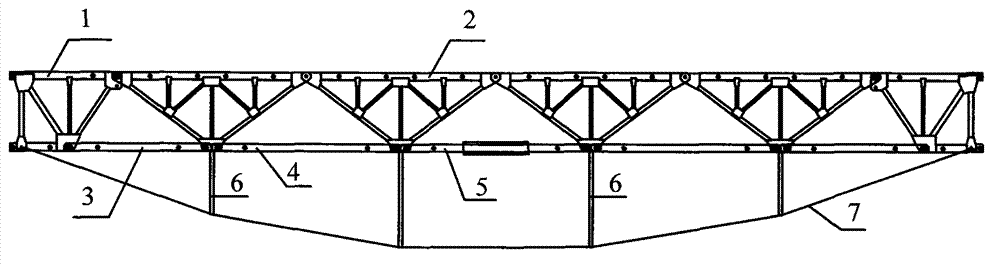

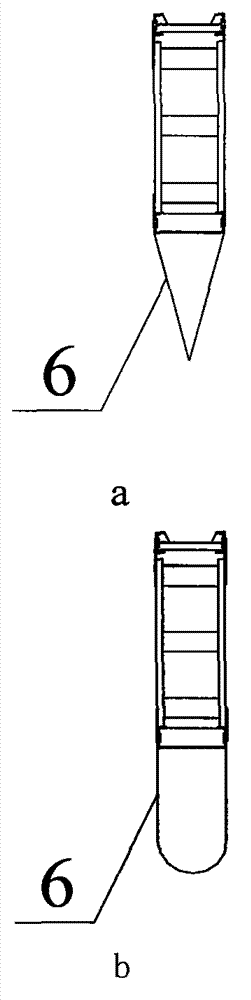

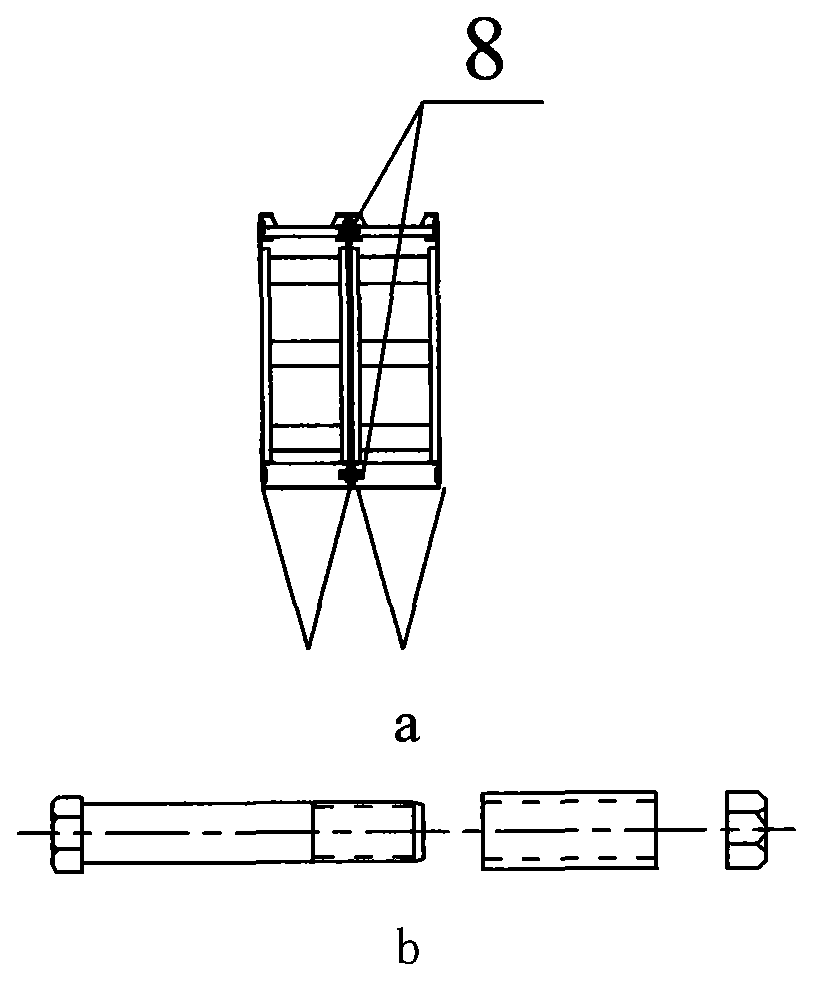

[0024] figure 1 A quick-assembled tension-string truss pedestrian steel bridge proposed by the present invention includes a bridge deck, bridge piers on both sides, and two or more main girders arranged under the bridge deck and arranged side by side along the cross-sectional direction. It is a chord main beam, including an assembled truss, a vertical strut 6 and a steel cable 7. The assembled truss consists of a standard triangular truss unit 2, an end triangular truss unit 1, an end chord 3, a standard chord 4, an adjustable The chords 5 are connected by steel pins. Standard triangular truss unit 2, end triangular truss unit 1 and end chord 3, standard chord 4, and adjustable chord 5 are connected by steel pins to form the upper truss of the chord main beam; The vertical strut 6 is then anchored to the other end of the truss to form a chord structure, and the line shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com