Method for monitoring power equipment in cable pit online through optical fiber sensing technology

An optical fiber sensing technology and technology for power equipment, applied in the field of power, can solve the problems that monitoring equipment is not easy to obtain electricity and is not intelligent enough, and achieves the effect of alleviating work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

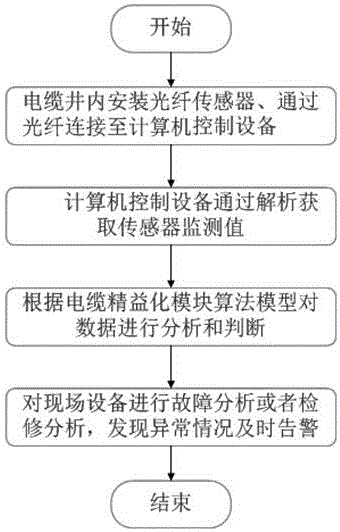

[0017] A method for realizing on-line monitoring of cable well power equipment through optical fiber sensing technology, comprising the following steps:

[0018] 1) The sensors installed in the cable shaft include the fiber optic temperature sensor for measuring the temperature of the cable body, the fiber optic temperature sensor for measuring the ambient temperature in the well, the fiber optic water level sensor, etc. The optical fiber cable is connected with the sensor and computer control equipment by pigtail fusion fiber.

[0019] Lay the optical cable to the nearest station building and connect to the computer control equipment;

[0020] 2) The computer control equipment analyzes the spectral data according to the characteristics of each parameter, and obtains the sensor monitoring value;

[0021] 3) The monitoring data is connected to the intranet of the electric power company, and first collected into the "intelligent inspection and control platform", and the data is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com