Ball sealer for water inlet of dam bottom hole bypass pipe and method for replacing dam bottom hole bypass valve

A replacement method and bypass valve technology, which is applied in water conservancy projects, sea area projects, construction, etc., can solve problems such as difficult replacement and damage to water filling valves, and achieve the effects of saving valve replacement costs, reducing safety hazards, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

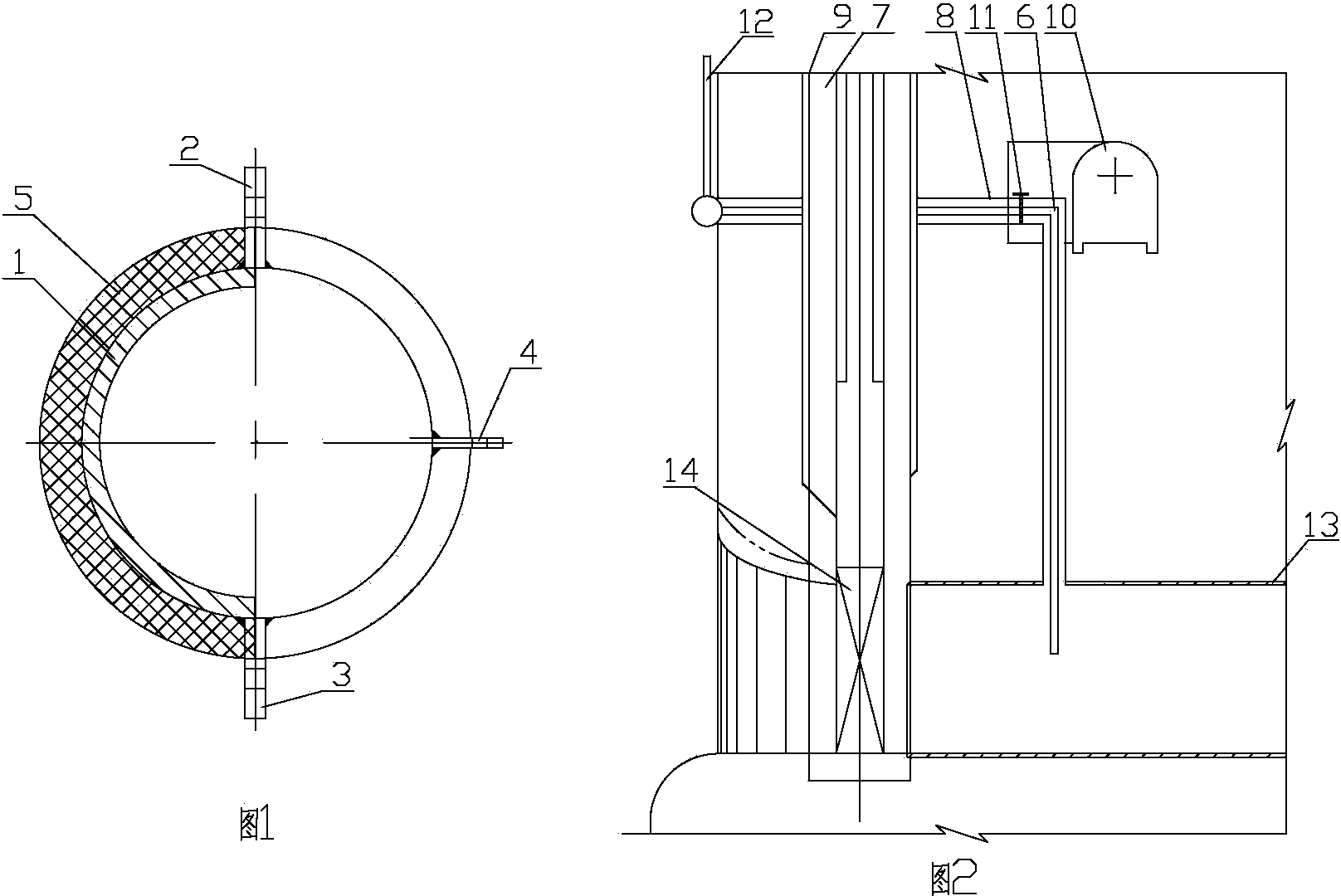

[0021] Example 1, such as figure 1 As shown, the dam bottom hole bypass pipe water inlet sealing ball includes a ball 1; the surface of the ball 1 is fixed with lifting lugs 2.

[0022] According to actual needs, the above-mentioned dam bottom hole bypass pipe water inlet plugging ball can be further optimized or / and improved:

[0023] like figure 1 As shown, a suspension ring 3 is fixed on the surface of the ball 1 corresponding to the other end of the suspension ear 2 , and a side pull ring 4 is fixed on the surface of the ball between the suspension ear 2 and the suspension ring 3 . Counterweight is installed on suspension ring 3, how many and weight of counterweight are determined according to the depth of water and the speed of current.

[0024] like figure 1 Shown, the surface of ball 1 is fixed with one deck soft rubber 5. Soft rubber 5 is mainly in order to enhance sealing performance, can effectively block nozzle, prevents the jet of water that causes because o...

Embodiment 2

[0026] Example 2, such as figure 2 As shown, a method for replacing the dam bottom hole bypass valve using the water inlet plugging ball of the dam bottom hole bypass pipe is carried out according to the following steps: the first step, at first fixedly install the winch on the dam surface 9, and place the The lifting lug 2 on the ball 1 is fixedly connected with the winch through the steel wire rope 12, the bypass water filling valve 11 is closed, and then the water inlet sealing ball of the bypass pipe at the bottom hole of the dam is lowered to seal the water inlet of the bypass pipe at the bottom hole of the dam. The blocking ball is positioned at the water inlet of the bottom hole gate bypass pipe 8 on the left side of the dam 7; the second step: build an installation platform in the corridor 10 on the right side of the dam 7, and prepare a new bypass water filling valve 11; The third step is to open the bypass water filling valve 11, and the water inlet sealing ball of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com