Foundation pit supporting structure of underground continuous wall and construction method for foundation pit supporting structure

A support technology for underground diaphragm walls and foundation pits. It is applied in the direction of foundation structure engineering, excavation, and sheet pile walls. It can solve the problems of slowing down the construction speed, increasing the cost of reinforcement materials, and increasing the weight of the reinforcement cage, so as to speed up the construction. Effect of material cost reduction and groove wall depth reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

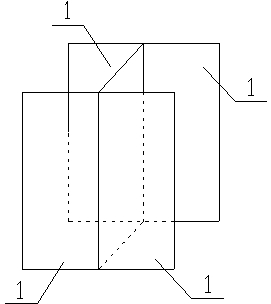

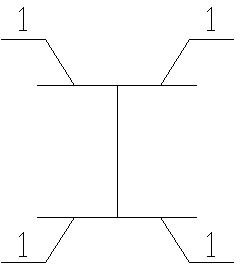

[0045]A foundation pit in Hexi, Nanjing City, Jiangsu Province is 12m deep and 7m long on one side. From the site surface to 4m below the ground is silty clay, below 4m is silt, and 1.5m below the ground is groundwater. 10m outside the side wall of the foundation pit is Nanjing Metro Line 2. In order to ensure the absolute safety of Metro Line 2, it is necessary to prevent the water and soil outside the foundation pit from flowing into the foundation pit. The multifunctional function of the wall—retaining soil, stopping water, and carrying vertical force as the outer wall of the building. The ground connection wall is 7m in length, 12m in depth and 1m in width. It is composed of a unit groove section 7 and two steel plate column 2 joints. The unit groove section 7 is 6m in length, 12m in depth and 1m in width. The design depth is 3 and the extension part 4 is 12m. The length of the steel plate column 2 parallel to the extension direction of the wall is 0.5m, and the width of...

Embodiment 2

[0048] A foundation pit on Zhongshan Road, Nanjing City, Jiangsu Province is 12m deep and 7m long on one side. From the site surface to 4m below the ground is clay, below 4m is sandy soil, and 1m below the ground is groundwater. The 5m outside the side wall of the foundation pit is Nanjing Metro Line 1 and Zhongshan Road, a transportation hub in Nanjing. In order to ensure the absolute safety of Metro Line 1 and Zhongshan Road, the transportation hub, it is necessary to prevent the water and soil outside the foundation pit from flowing into the foundation pit. At the same time, in order to reduce construction investment, the owner decided to install a ground connection wall between the foundation pit and the side wall of the foundation pit. , to give full play to the multi-functional role of the ground connection wall - retaining soil, stopping water, and carrying vertical force as the outer wall of the building. The ground connection wall is 7m in length, 12m in depth and 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com