Water draining and flushing mechanism

一种排水阀、止水的技术,应用在带水箱的冲洗设备、供水装置、薄料处理等方向,能够解决冲刷系统与坐便器配合设计限制、结构体积大、组装及维修复杂等问题,达到冲刷功能容易保证、尺寸减小、拓宽设计空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

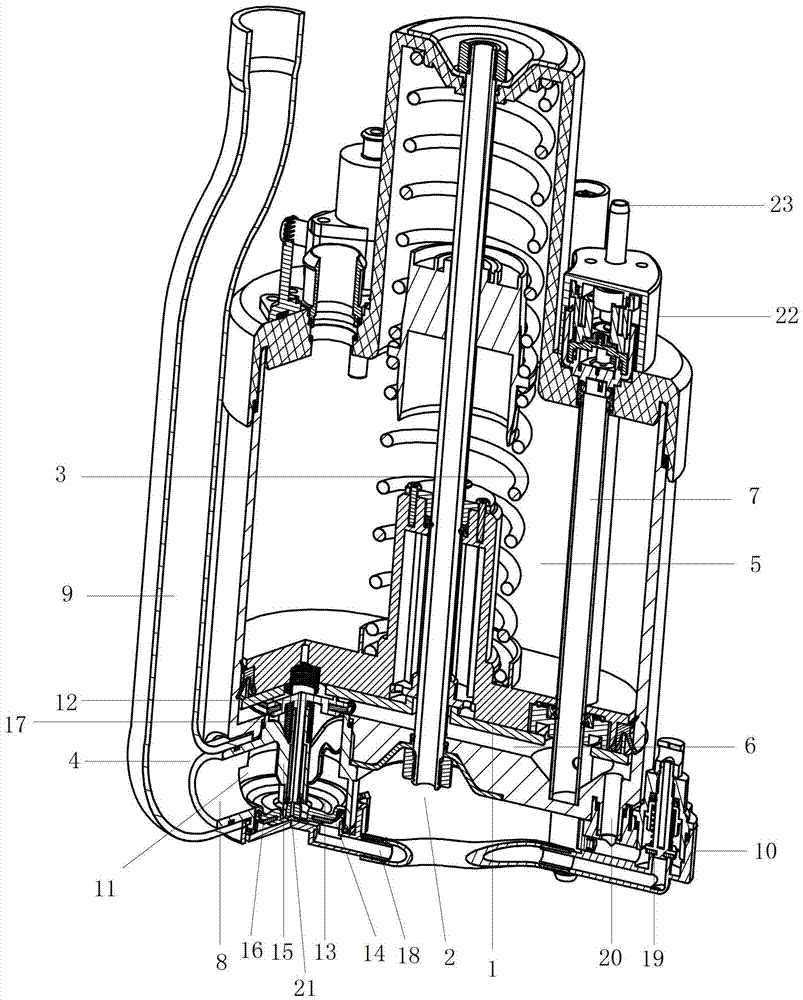

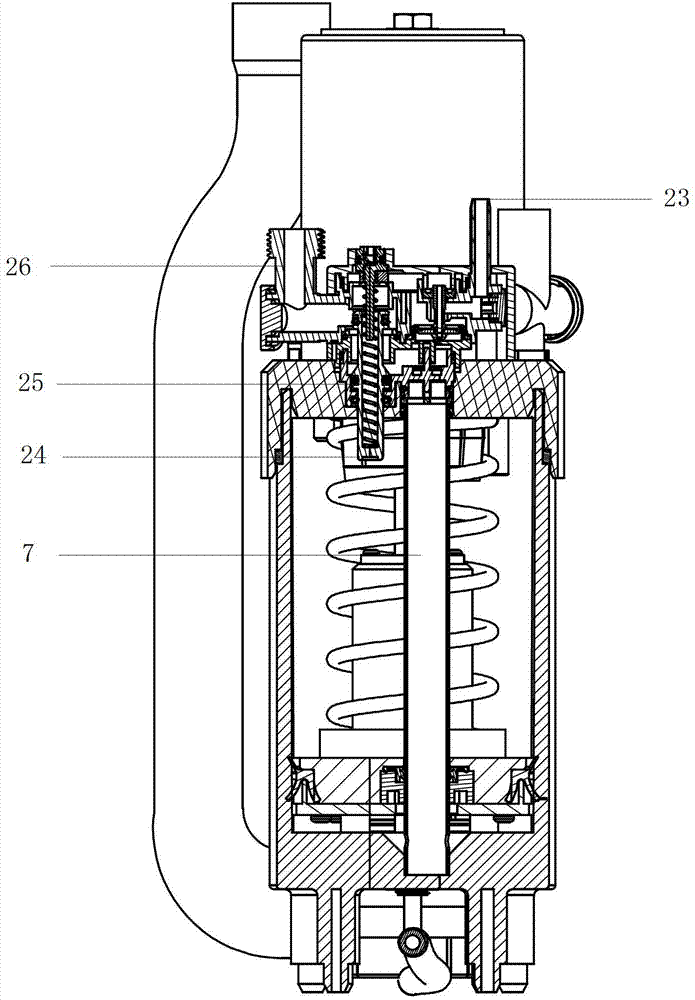

[0047] as attached figure 1 , 2 As shown, the external water source is connected to the water inlet joint 26 on the water inlet control assembly 22 . A part of water replenishes water to the toilet through the replenishment channel 23 of the water inlet and stop water control assembly 22, and another part of water enters the lower box body 6 through the water inlet pipe 7 through the inner cavity of the water inlet and stop water control assembly 22.

[0048] When using for the first time, the inlet of drain valve 4 is closed naturally. Now the water pressure acts on the drain valve 4 water-stop seal 12, the water-stop seal 12 seals the inlet of the drain valve 4, and the water is accumulated in the casing. Due to the effect of water pressure, the first piston 1 moves upward against the pressure of the main energy storage spring 3 . When the first piston 1 moves to a preset position, the first piston 1 pushes the travel switch 24 on the water stop control assembly 22 to clo...

Embodiment 2

[0054] The drain valve 4 of this embodiment is different from that of Embodiment 1, and the rest are basically the same.

[0055] as attached figure 1 , 2 , 3, the external water source is connected to the water inlet connector 26 on the water inlet control assembly 22 . A part of water replenishes water to the toilet through the replenishment channel 23 of the water inlet and stop water control assembly 22, and another part of water enters the lower box body 6 through the inner cavity of the water inlet and stop water control assembly 22 through the water inlet conduit.

[0056] When using for the first time, the drain valve 4 inlets are naturally closed. Now the water pressure acts on the drain valve 4 water-stop seal 12, the water-stop seal 12 seals the inlet of the drain valve 4, and the water is accumulated in the casing. Due to the effect of water pressure, the first piston 1 moves upward against the pressure of the main energy storage spring 3 . When the first pisto...

Embodiment 3

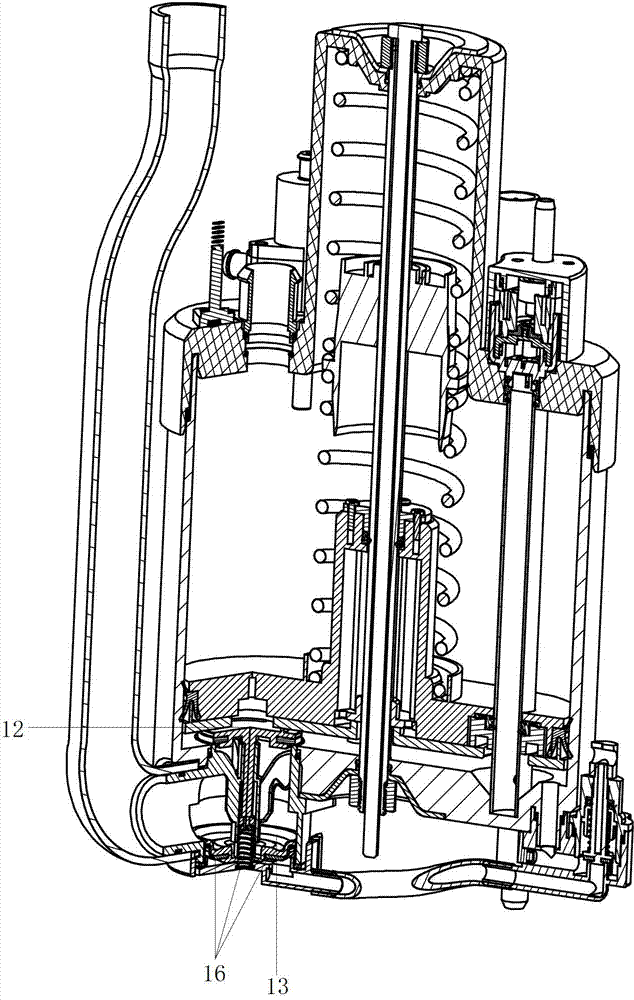

[0062] The water-tight seal 12 of this embodiment is different from that of Embodiment 1, and the rest are basically the same.

[0063] (The water-stop seal 12 shown here rotates around a fixed axis).

[0064] Such as figure 1 , 2 , 4 and 5, the external water source is connected to the water inlet connector 26 on the water inlet control assembly 22 . A part of water replenishes water to the toilet through the replenishment channel 23 of the water inlet and stop water control assembly 22, and another part of water enters the lower box body 6 through the inner cavity of the water inlet and stop water control assembly 22 through the water inlet conduit.

[0065] When using for the first time, the drain valve 4 inlets are naturally closed. Now the water pressure acts on the drain valve 4 water-stop seal 12, the water-stop seal 12 seals the inlet of the drain valve 4, and the water is accumulated in the casing. Due to the effect of water pressure, the first piston 1 moves upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com