Double-wet type dead axle and planet compound type mechanical speed change mechanism used for high-speed vehicle

A speed change mechanism and mechanical speed change technology, applied in the field of vehicle engineering, can solve the problems of wheeled vehicles not adopting a high-performance multi-degree-of-freedom transmission system design scheme, slow progress in the development of planetary multi-degree-of-freedom comprehensive transmission, and inability to meet stereotypes and practicality. , to achieve the effect of simple and reliable structure, smooth, fast and soft shifting process, and strong deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

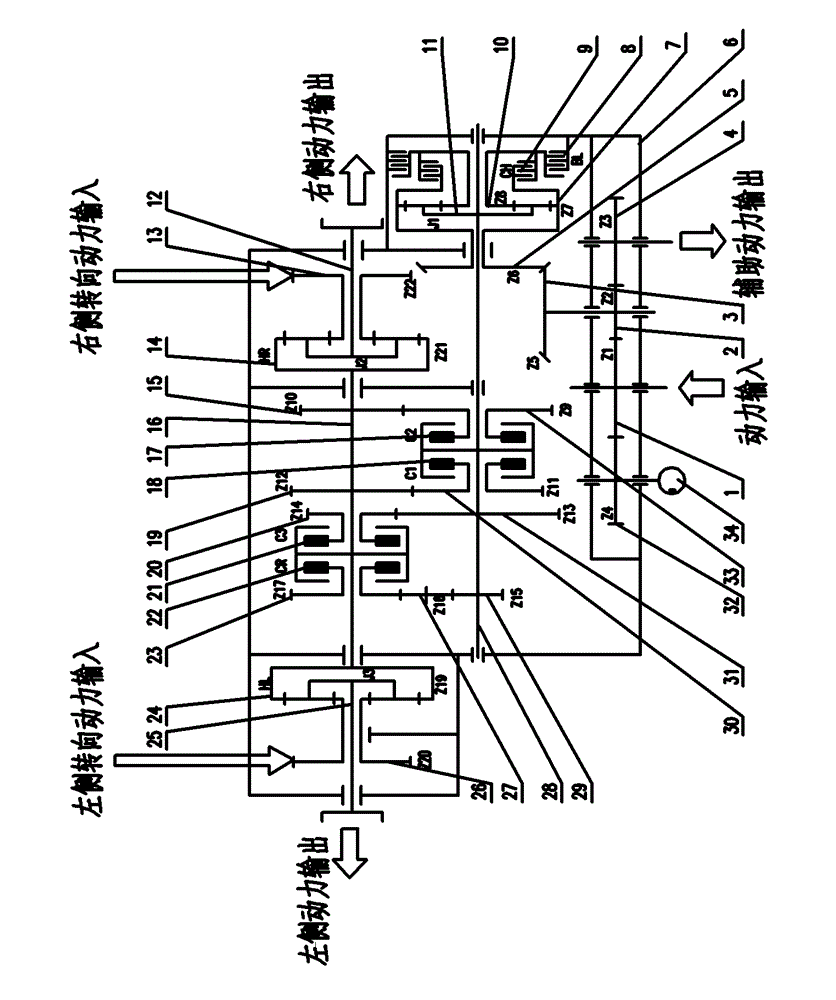

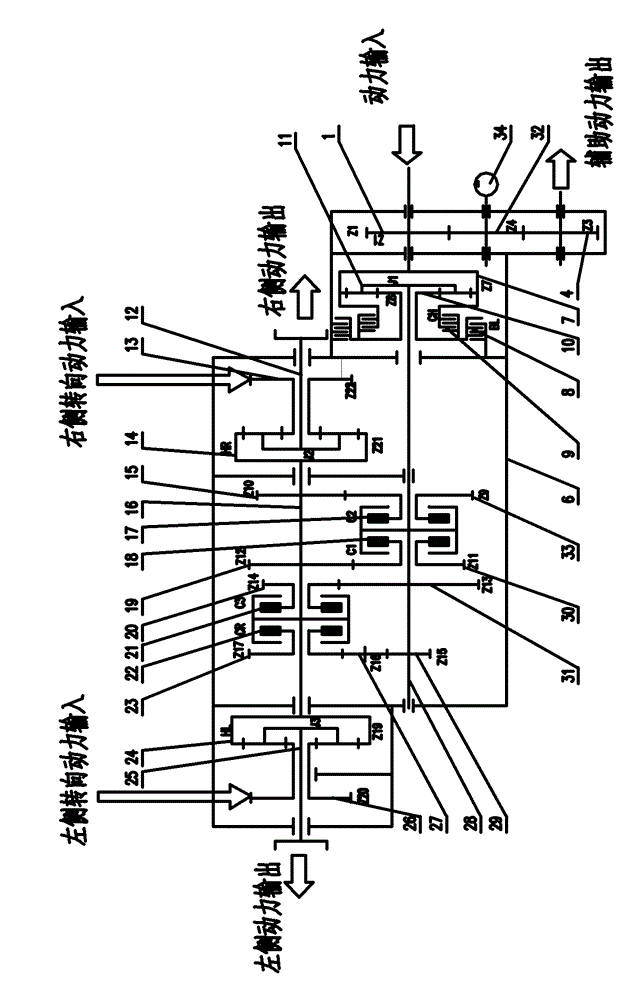

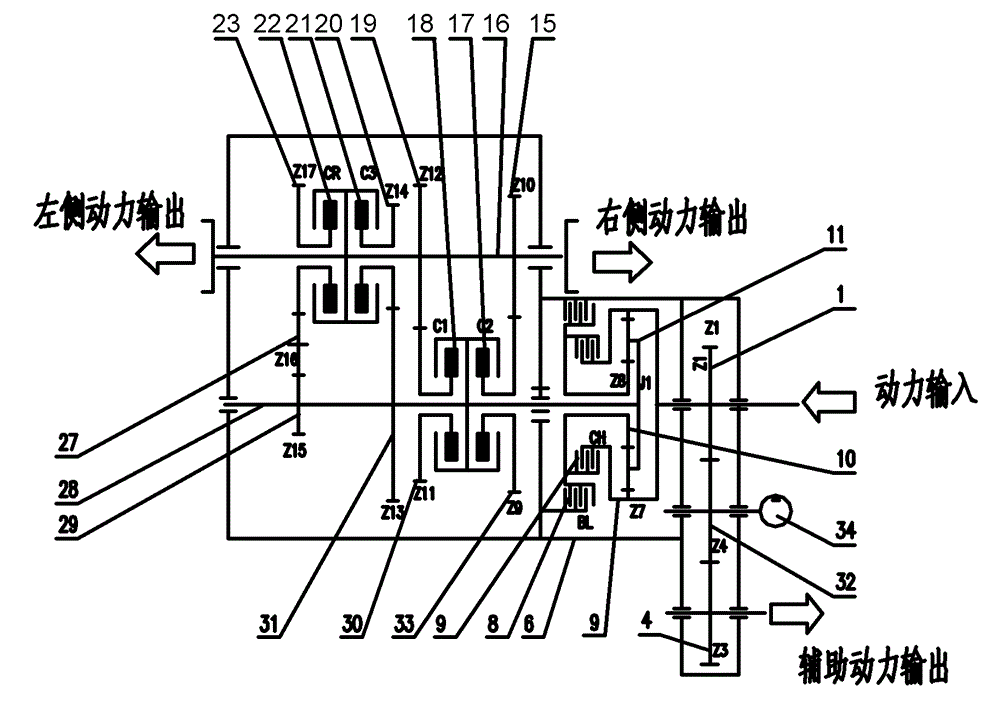

[0019] Such as figure 1 As shown, when the compound mechanical transmission mechanism is applied to a high-speed crawler vehicle with a longitudinally arranged engine, the power input is transmitted to the split gear 2 through the power input gear 1 for power split, and the split power is input in parallel to the direct drive transmission power The driving bevel gear 3 of the flow and the driving gear 4 of other power flows such as steering power flow, fan driving power, etc.; figure 2 As shown, when the compound mechanical transmission mechanism is applied to a high-speed crawler vehicle with the engine horizontally arranged, the power input is split at the power input gear 1 of the compound mechanical transmission mechanism, and the direct driving power flow is directly transmitted to the two-degree-of-freedom planet The ring gear 7 of the speed change mechanism, and other power flows such as steering power flow, fan driving power, etc. are transmitted from the power input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com