Testing method for water stability differences of bituminous mixture after crushing coarse aggregates

A technology of asphalt mixture and testing method, applied in the direction of material inspection products, etc., can solve the problems of asphalt mixture performance change, affecting asphalt mixture performance and use quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

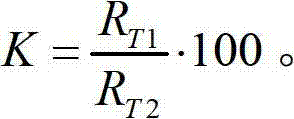

[0040] Example 1, Test of Asphalt Mixture Grading Variability after Coarse Aggregate Crushing

[0041] 1. AC-20C asphalt mixture is used in the surface layer of a highway, the crushing value of limestone coarse aggregate is 24%, and the content of needle flake particles is 16%, all of which meet the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004) Table 4.8.2 has technical requirements for the quality of coarse aggregate for asphalt mixture, which is close to the upper limit of the allowable range;

[0042] 2. At the construction site, 2kg of mixture was randomly selected from the auger of the paver, and the asphalt was separated from the mixture according to the test method T0722-1993 of "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTJ052-2000) ;

[0043] 3. According to the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTJ052-2000) T0725-2000 test method, sieve the mixed minera...

Embodiment 2

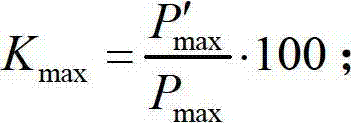

[0048] Example 2, High temperature deformation resistance test of asphalt mixture after coarse aggregate crushing

[0049] 1. AC-20C asphalt mixture is used in the surface layer of a certain expressway that is the same as Example 1. The crushing value of limestone coarse aggregate is 24%, and the content of needle-like particles is 16%, all of which meet the requirements of "Highway Asphalt Table 4.8.2 of Technical Specifications for Pavement Construction (JTGF40-2004) has technical requirements for the quality of coarse aggregate for asphalt mixture, which is close to the upper limit of the allowable range;

[0050] 2. At the construction site, 6 core samples were randomly selected. First, the diameter, height and relative bulk density of the core samples were measured according to the test method T0705-2000 of "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTJ052-2000) , the test results are shown in Table 1, and then, according to the test metho...

Embodiment 3

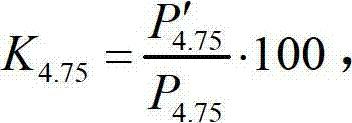

[0053] Example 3, Water Stability Test of Asphalt Mixture after Coarse Aggregate Crushing

[0054] 1. AC-20C asphalt mixture is used in the surface layer of a certain expressway that is the same as Example 1. The crushing value of limestone coarse aggregate is 24%, and the content of needle-like particles is 16%, all of which meet the requirements of "Highway Asphalt Table 4.8.2 of Technical Specifications for Pavement Construction (JTGF40-2004) has technical requirements for the quality of coarse aggregate for asphalt mixture, which is close to the upper limit of the allowable range;

[0055] 2. At the construction site, 12 mid-surface core samples were randomly selected, and the diameter D and height h of the samples were measured. The test results are shown in Table 3. The samples were randomly divided into 2 groups, 6 in each group, and the first The group of samples is placed on the platform and stored at room temperature for later use;

[0056]3. According to the test m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com