Method for manufacturing semiconductor device

A semiconductor and chip technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of reduced reliability and inability to distribute semiconductor chips evenly, and achieve uniform distribution in the plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

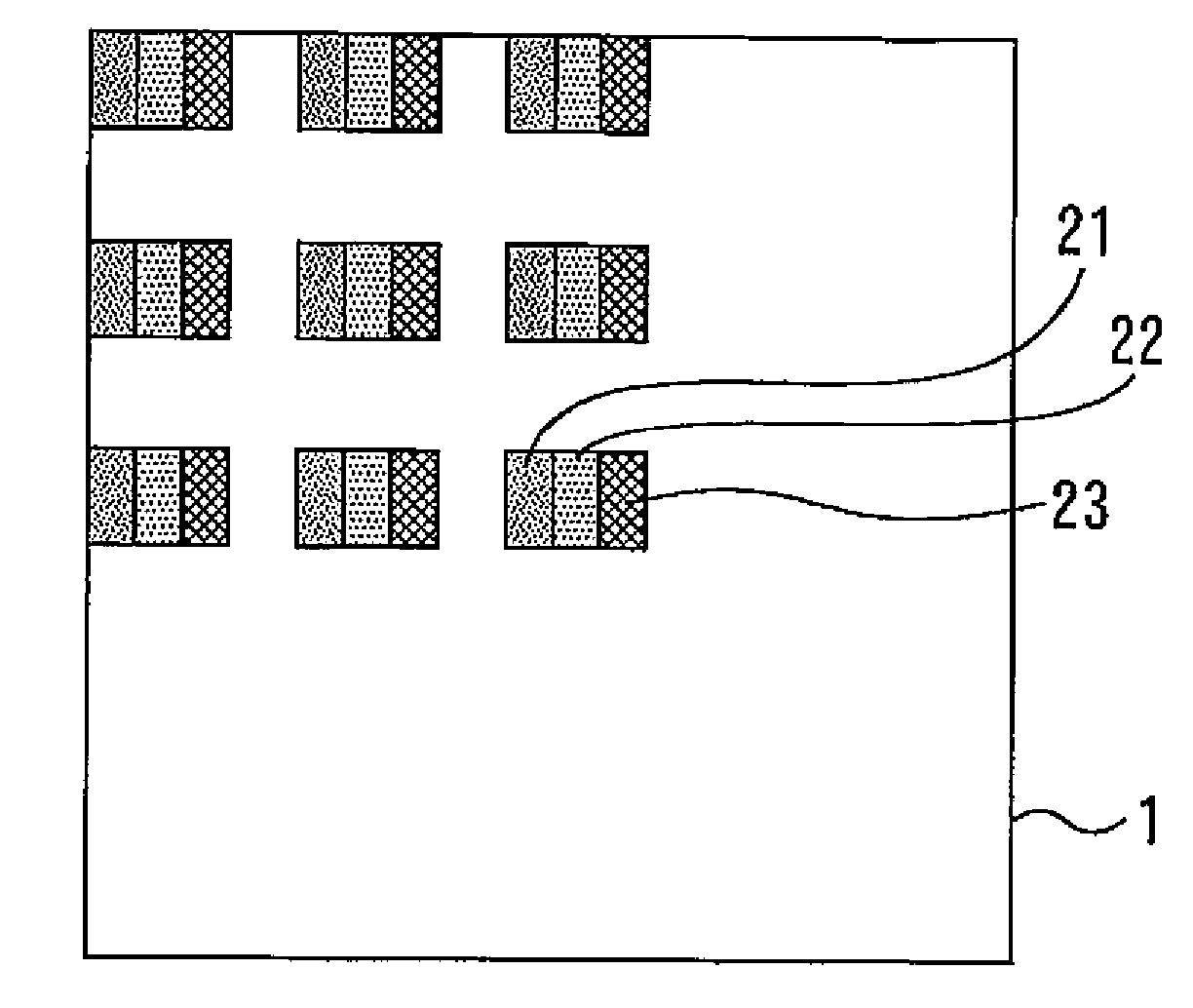

[0023] figure 1 It is a cross-sectional view showing a semiconductor device according to an embodiment of the present invention. The back surface of the semiconductor chip 1 is bonded to an electrode substrate 3 with a conductive bonding material 2 . The conductive bonding material 2 is solder, Ag paste, conductive adhesive, or the like. The electrode substrate 3 is mounted on a heat sink 5 via an insulating sheet 4 having excellent thermal conductivity. The surface of the semiconductor chip 1 is connected to external wiring terminals 7 by wires 6 such as Al or Cu. The semiconductor chip 1 , a part of the electrode substrate 3 , the insulating sheet 4 , a part of the heat sink 5 , the wire 6 , and a part of the external wiring terminal 7 are sealed with an insulating resin 8 .

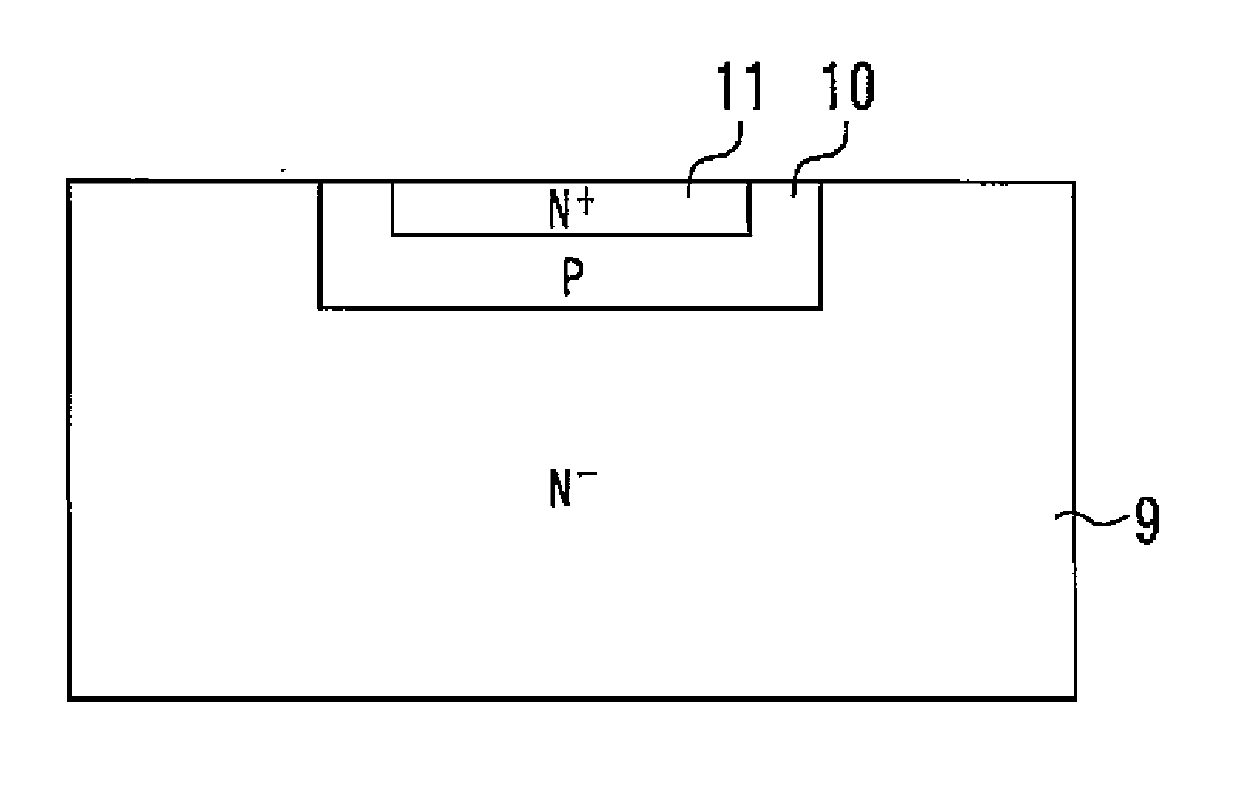

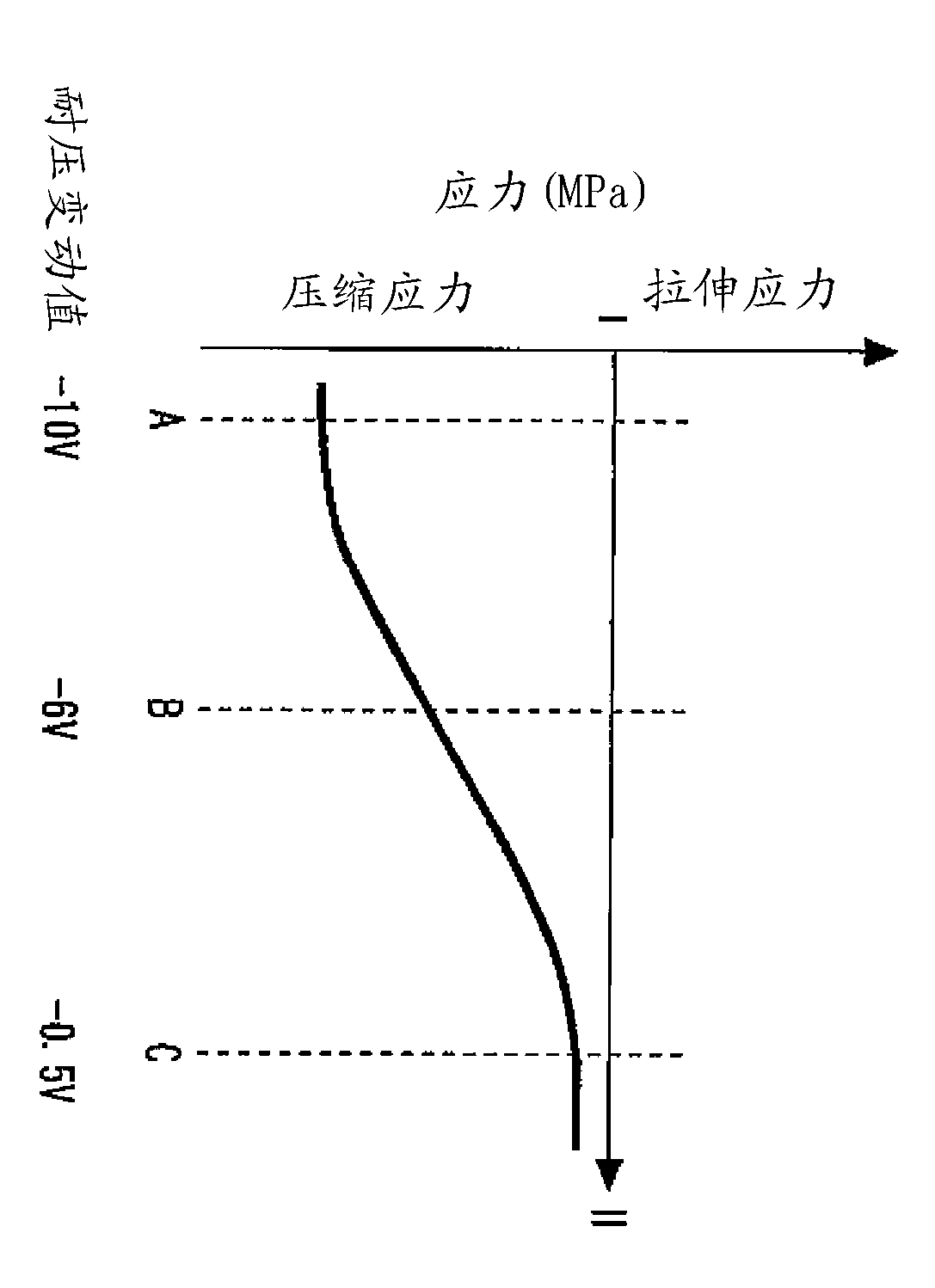

[0024] Next, the manufacturing process of the semiconductor chip 1 will be described with reference to the drawings. Figure 2 to Figure 8 It is a sectional view showing the manufacturing process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com