Crystalline polymer microporous membrane, its preparation method, and filter for filtration

A crystalline polymer, microporous membrane technology, used in other household appliances, chemical instruments and methods, membranes, etc., can solve problems such as particle leakage, and achieve the effect of long filtration life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

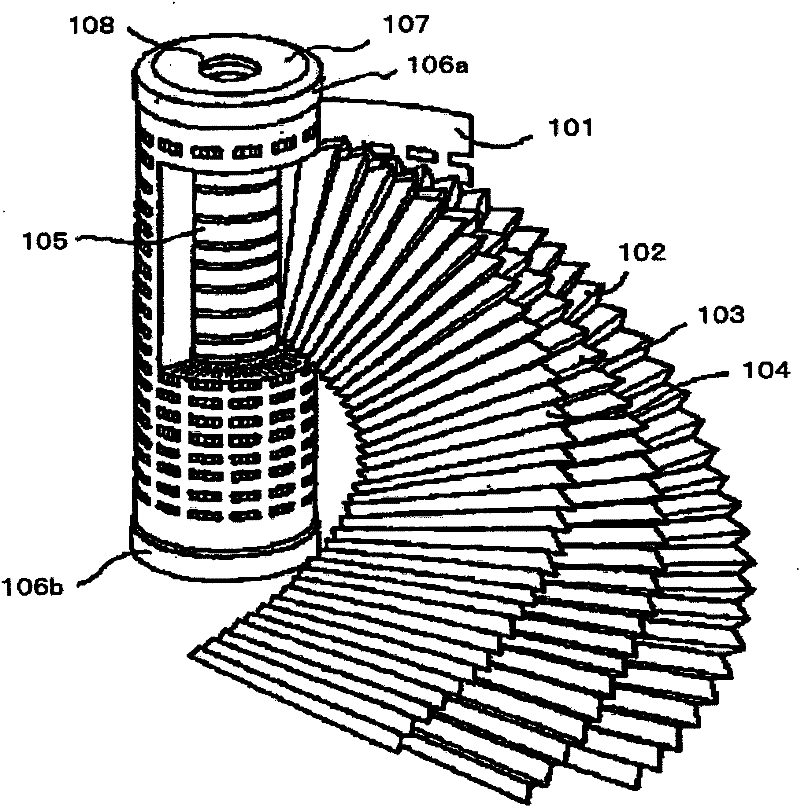

[0059] The production method of the crystalline polymer microporous membrane of the present invention includes at least a step of asymmetric heating and a stretching step, and if necessary, other steps such as a crystalline polymer film production step and a hydrophilization step.

[0060] The crystalline polymer microporous membrane of the present invention is prepared by the preparation method of the crystalline polymer microporous membrane.

[0061] Next, the crystalline polymer microporous membrane of the present invention will be described in detail through the description of the production method of the crystalline polymer microporous membrane of the present invention.

[0062] Note that in the following description, a film surface provided with a larger average pore diameter is described as a "non-heated surface", and a film surface provided with a smaller average pore diameter is described as a "heated surface". In this specification they are named as such only for con...

Embodiment 1

[0229]

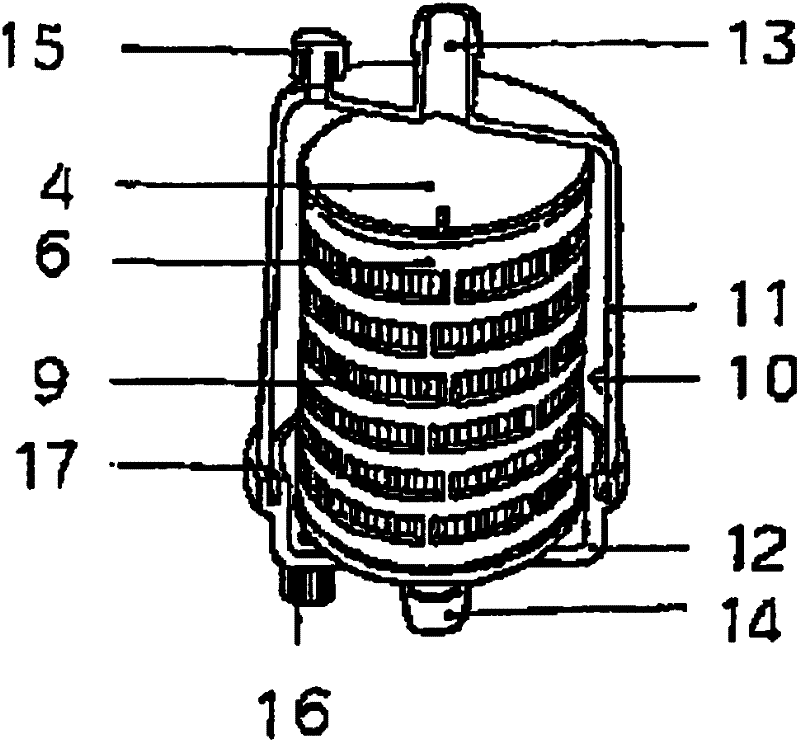

[0230] To 100 parts by mass of polytetrafluoroethylene fine powder ("POLYFLON FINE POWDER FI04U", manufactured by Daikin Industries Ltd.) with a number average molecular weight of 6,200,000, 27 parts by mass of hydrocarbon oil ("ISOPER", available as extrusion aid) was added. obtained from Esso Oil Co., Ltd.), extruding the mixture in a round stick-shaped paste. The paste was rolled at a rolling speed of 30 m / min with a rolling roll heated to 60° C. to prepare a polytetrafluoroethylene film. The polytetrafluoroethylene film was passed through a hot air drying oven heated to 250° C. to dry and remove the extrusion aid to prepare an unfired polytetrafluoroethylene film with an average thickness of 120 μm, an average width of 150 mm, and a specific gravity of 1.55.

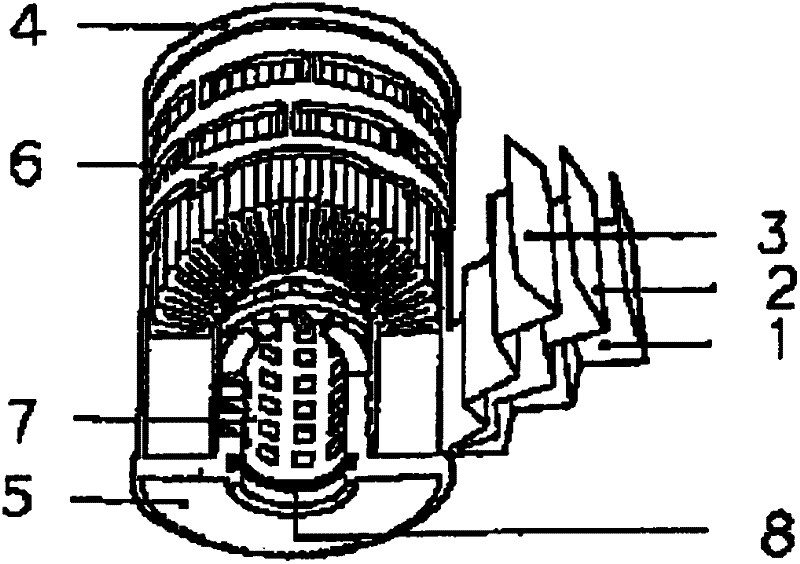

[0231] use Figure 4 The single-sided heater, by pressing the belt unit ( Figure 4 The "41" of ") under the pressing pressure of 1MPa, one surface of the obtained polytetrafluoroethylene and the annular...

Embodiment 2

[0247] Prepare the polytetrafluoroethylene microporous membrane of embodiment 2 in the same manner as embodiment 1, just use Figure 5 The single-sided heater described in replaces the single-sided heater in Example 1.

[0248] Described below Figure 5 The structure of the single-sided heater described in .

[0249] ●Heating roller (heater) ( Figure 5 "51")

[0250] Induction heating system, diameter: 300mm; width: 300mm; material: steel

[0251] ●Press belt unit ( Figure 5 "41")

[0252] Annulus ( Figure 5 "43"):

[0253] Width: 300mm; Length: 1,800mm; Thickness: 0.2mm; Material: SUS304H

[0254] endless belt roller ( Figure 5 "45")

[0255] Diameter: 100mm; Material: Steel

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com