Fabrication method of photomask-blank

A manufacturing method and technology of photomasks, which are applied in the direction of originals for photomechanical processing, photolithographic process of patterned surfaces, semiconductor/solid-state device manufacturing, etc., can solve the problem of insufficient flatness of photomasks, particle adhesion, Affect the production yield and other issues, to achieve the effect of uniform distribution in the plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

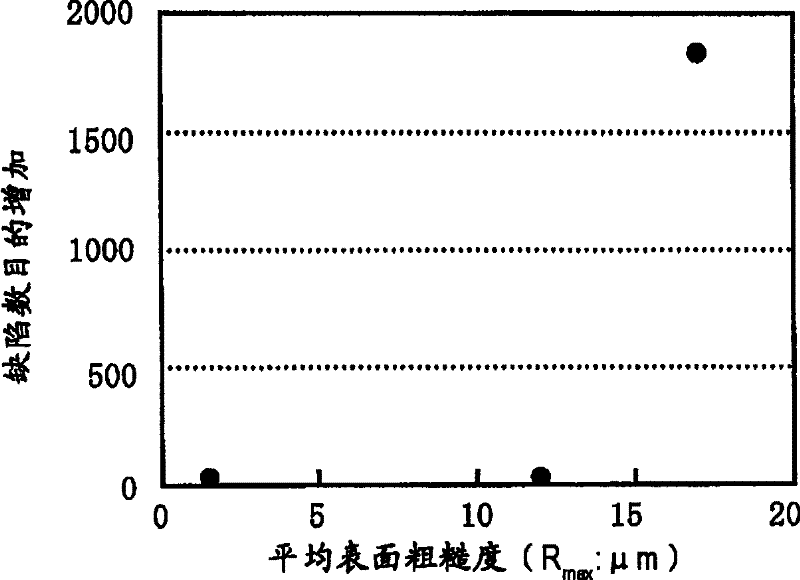

[0068] (Example 1: Reducing roughness of indoor surfaces)

[0069] This example concerns a technique for reducing particle generation during the flash treatment step by reducing the roughness of the chamber surfaces.

[0070] The inventors' studies have demonstrated that when the surface of a jig in a chamber or the inner wall of a chamber is irradiated with a flashlight, multiple reflection etc. cracking, resulting in fine particles.

[0071] In order to prevent partial cracking of the indoor surface due to expansion or contraction of the material of the indoor surface, quartz glass can be effectively used.

[0072] Thus, in the following description, unless otherwise specifically stated, it is assumed that the chamber and the jig such as the susceptor accommodated in the chamber are made of quartz glass. As described in detail below, quartz glass has another advantage: since its transmittance to glints can be easily controlled, the amount of light energy imparted to the su...

example 2

[0101] (Example 2: Study on the pressure in the chamber)

[0102] This example concerns the effect of pressure in the chamber on particle generation during flash exposure.

[0103] It has been demonstrated by the inventors' studies that by reducing the pressure in the chamber where the flash irradiation occurs, the generation of particles can be effectively suppressed.

[0104] According to the prior art, when flash irradiation is performed, once the chamber is evacuated, nitrogen gas is introduced into the chamber through a filter capable of removing, for example, particles of 0.1 μm diameter, and then the cleaned nitrogen gas is flowed at atmospheric pressure Perform flash exposure. However, it has been proved by experiments that if flash irradiation is performed under atmospheric pressure in this way, a large number of defects appear with a certain probability (frequency). The inventors considered this phenomenon as follows.

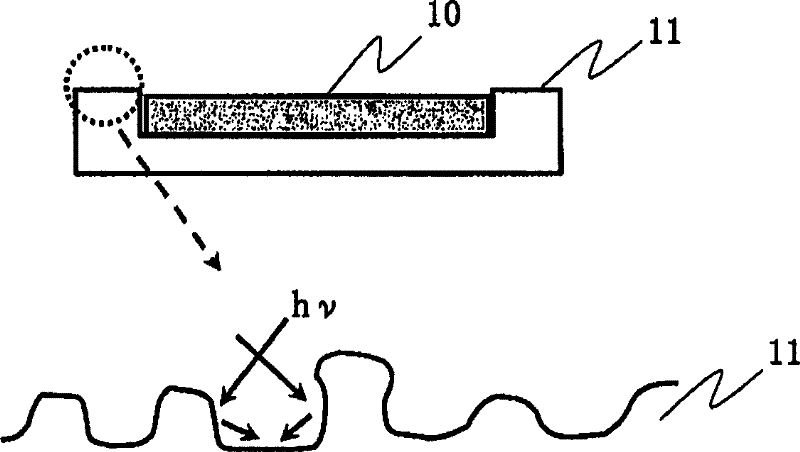

[0105] Figure 3A and 3B is a diagram illu...

example 3

[0121] (Example 3: Structure of the base 1)

[0122] This example relates to a structure of a susceptor on which a substrate is mounted during flash irradiation, which is intended to reduce particles generated during flash irradiation by minimizing the amount of irradiation light from a flash lamp.

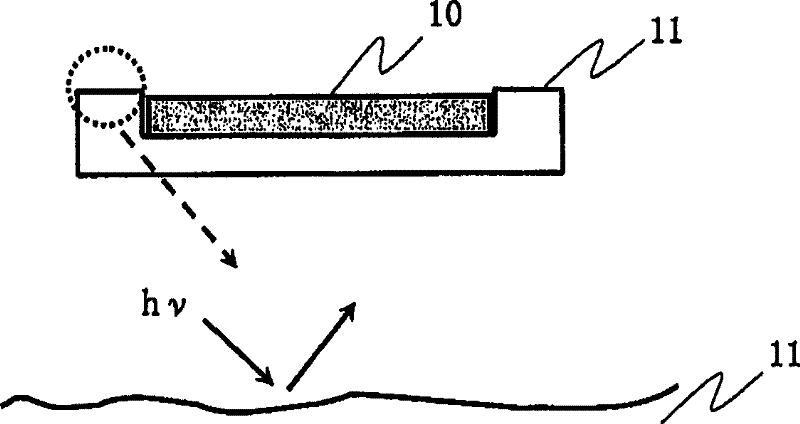

[0123] Figure 6A and 6B is a diagram for explaining the behavior of light from a flash lamp after being vertically incident on a substrate mounted on the susceptor and passing through the substrate with respect to susceptors of different structures. Figure 6A The bases shown in are made of clear quartz only, while Figure 6B The base shown in is made of opaque quartz only.

[0124] The term "pedestal" in this specification is used broadly to refer to a member for holding a substrate (or a member on which the substrate is mounted). Therefore, the shape of the base and the like are not limited to those shown in these drawings. In addition, the quartz glass described as the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com