Backward work laminator

A laminating machine and laminating technology, applied in the direction of plant protection cover, etc., can solve the problems of comfort and safety impact, and achieve the effect of improving safety, improving the operating environment and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

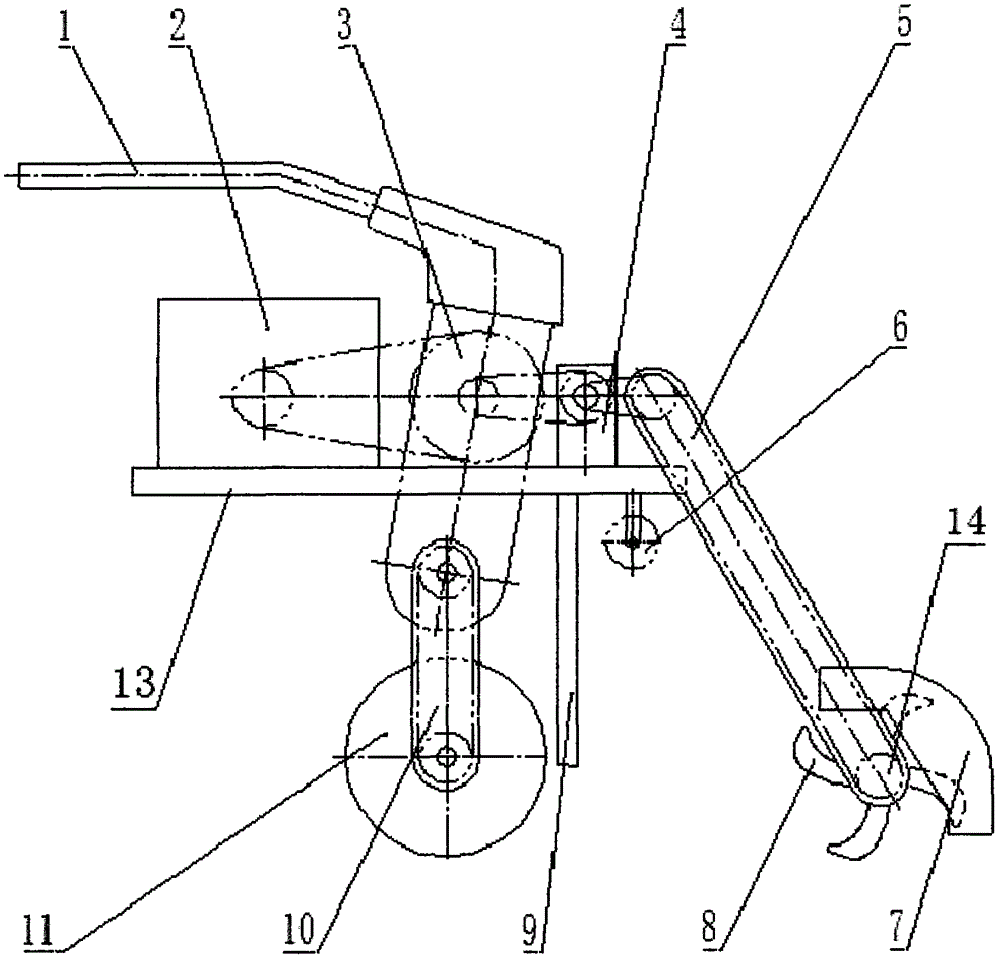

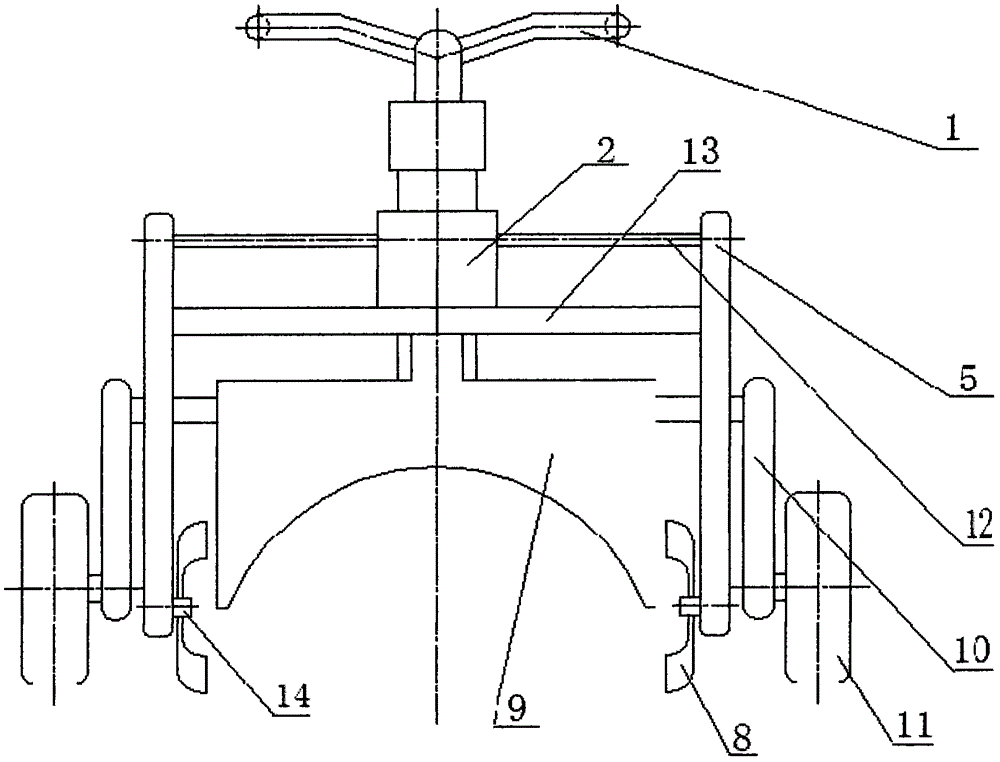

[0011] like figure 1 , 2 As shown, the backward action laminator of the present invention includes a base 13, an engine 2, a gearbox 3 and a clutch 4 located above the base 13, a ridge trimmer 9 and a film roll 6 located below the base 13, and the variable speed The box 3 is respectively connected with the engine 2 and the operating handle 1, the output shaft of the gearbox 3 is connected with a suspension device 10, the suspension device 10 is provided with a traveling wheel 11, the clutch 4 is connected with the gearbox 3 The clutch 4 is also connected with a transmission shaft 12, the transmission shaft 12 is connected with a transmission box 5, and the transmission box 5 is connected with a soil-cultivating knife 8, and a soil-guiding cover 7 is provided on the soil-cultivation knife 8.

[0012] The output shaft of the gearbox 3 transmits the power to the traveling wheel 11 through the suspension device 10 in a sprocket transmission manner. The cultivating knife 8 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com