Microwave-still air combined thawing process for frozen tuna bars

A tuna and microwave technology, applied in the direction of preservation of meat/fish by freezing/cooling, etc., can solve the problems of short time consumption and uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

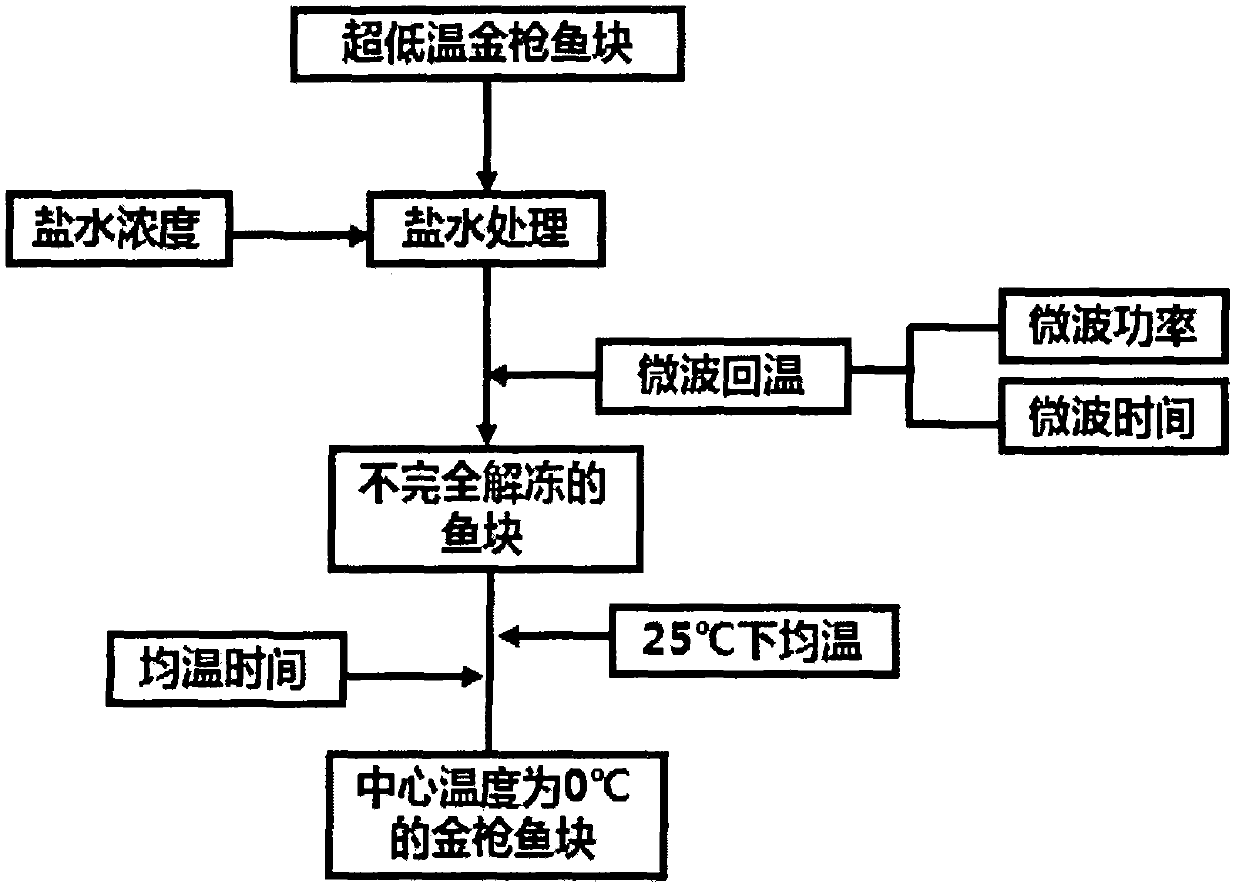

Method used

Image

Examples

Embodiment 1

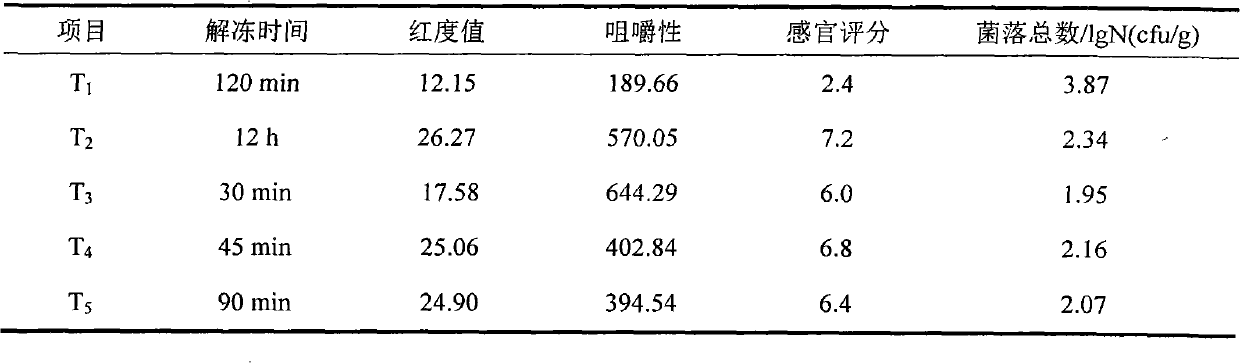

[0014] After the ultra-low temperature frozen fish pieces were treated with 3% salt water, under the power condition of 170W, microwave time of 8min was selected for microwave rewarming, and then the temperature was averaged at 25°C for 120min.

[0015] Through the measurement of physicochemical and sensory indicators, the redness value of the fish fillet was 18.41, the chewiness was 473.26, and the sensory score was 5.2. The color of the fish fillets is brighter, but the uniformity is poor, slightly elastic, and has no peculiar smell.

Embodiment 2

[0017] After the ultra-low temperature frozen fish pieces were treated with 2% salt water, under the power condition of 220W, microwave time of 4min was selected for microwave rewarming, and then the temperature was averaged at 25°C for 50min.

[0018] Through the measurement of physicochemical and sensory indicators, the redness value of the fish fillet was 18.65, the chewiness was 478.89, and the sensory score was 4.65. The fish fillets are brighter in color, slightly elastic, have no peculiar smell, have poor umami, and have a slightly fishy aftertaste.

Embodiment 3

[0020] After the ultra-low temperature frozen fish pieces were treated with 4% salt water, under the power condition of 300W, microwave time was selected for 1min for microwave rewarming, and then the temperature was averaged at 25°C for 120min.

[0021] Through the measurement of physicochemical and sensory indicators, the redness value of the fish fillet was 15.82, the chewiness was 246.47, and the sensory score was 2.5. The color of the fish fillet is slightly dark, the elasticity is poor, there is no peculiar smell, and the salty taste is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com