Hole distribution method and hole distribution device for circular structure

A ring-shaped structure and hole layout technology, which is applied in boring/drilling, drilling/drilling equipment, and drilling templates for workpieces, can solve problems such as inability to machine ring-shaped structures, and achieve mechanical processing inconvenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

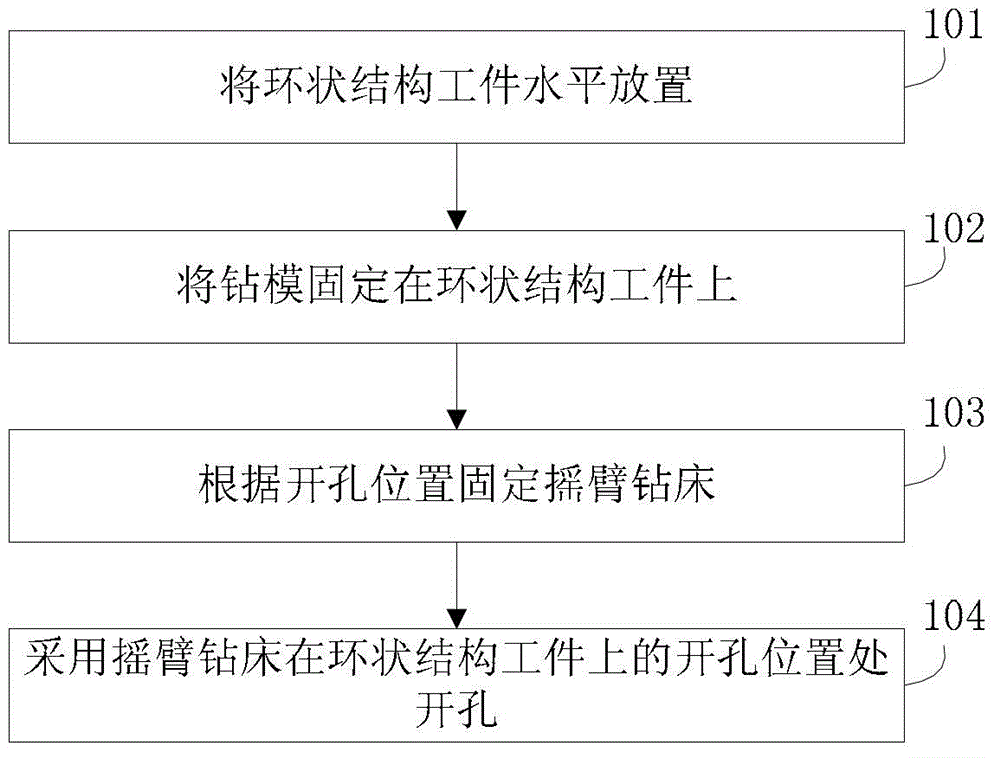

[0031] The embodiment of the present invention provides a ring structure hole layout method, see figure 1 , the method flow includes:

[0032] Step 101: Place the ring-shaped workpiece horizontally, and mark the opening position on the ring-shaped workpiece.

[0033] Step 102: Fix the drilling jig on the ring structure workpiece.

[0034] Adjust the drilling mold, place the drilling mold flat on the ring structure workpiece, align the center of the drill bush with the opening position, and spot weld the hollow pin to fix the drilling mold.

[0035] Step 103: Fix the radial drilling machine according to the opening position.

[0036] Specifically, place the radial drilling machine on the horizontal adjustment mechanism, adjust the level of the radial drilling machine with the four adjustment screws at the bottom of the horizontal adjustment mechanism, weld the compression plate to the horizontal adjustment mechanism after leveling, and lock the compression bolts on the nut. ...

Embodiment 2

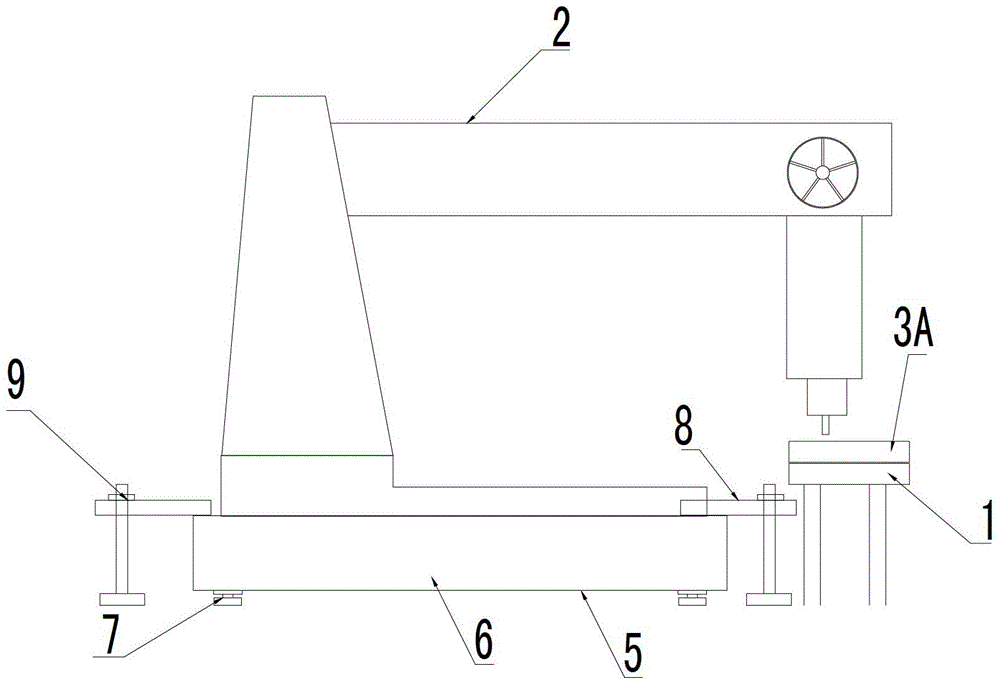

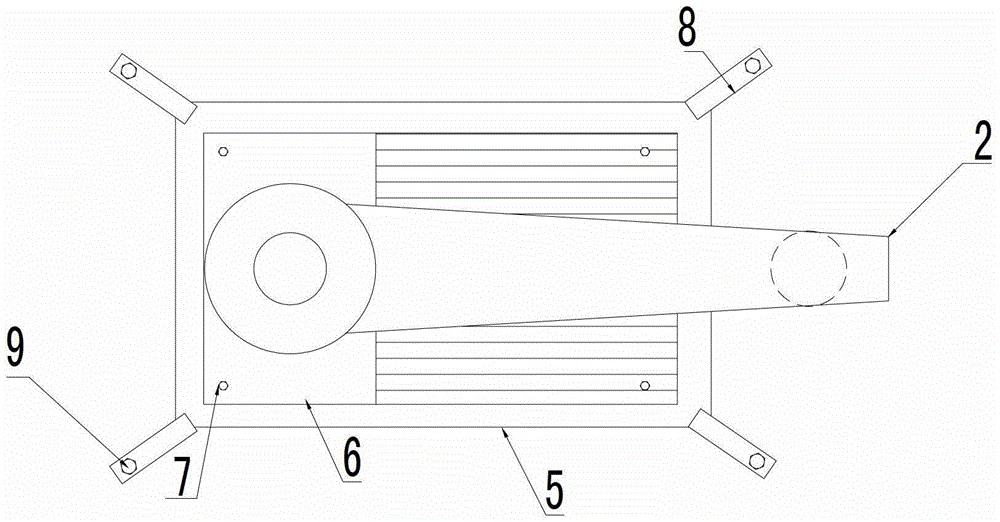

[0050] An embodiment of the present invention provides a device for distributing holes with a ring structure, see Figure 2-Figure 4, the device includes: a radial drilling machine 2 for drilling a ring structure workpiece 1, a drilling template 3 for guiding the radial drilling machine 2 to drill holes on the ring structure workpiece 1, and fixing the drilling template 3A on the ring The positioning structure on the workpiece 1 of the ring structure, and the opening position is marked on the workpiece 1 of the ring structure. When the device is in use, the drilling template 3A is fixed on the horizontally placed ring-shaped workpiece 1, and the radial drilling machine 2 is fixed according to the opening position to open the hole.

[0051] Further, the above-mentioned drilling template 3A is circular or arc-shaped, and the corresponding opening position on the drilling template 3A is provided with a drill bushing 3B, and the radius of the circle or arc passing through the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com