Mechanism for checking feeder

The technology of a feeder and a connecting rod, which is applied to the mechanism of the feeder and the mechanism of the consignment feeder, can solve the problems of complex structure, easy damage and high cost, and achieve the effect of overcoming the complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

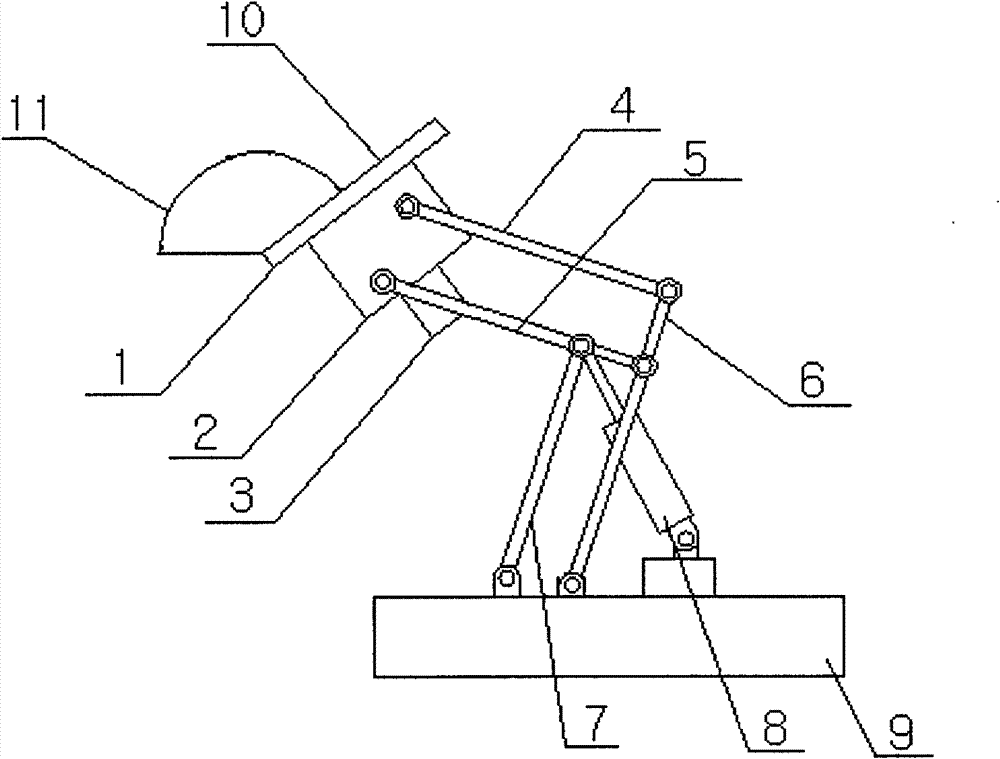

[0008] The consignment conveyor has a single-action connecting rod 4, and the single-acting connecting rod 4, double-acting connecting rod 5, automatic connecting rod 6, and single- and double-acting connecting rod 7 are hinged at corresponding positions with pins, and at the same time, the pins are used to connect the electromagnetic Suction cup 1, reducer 2, and stepping motor 3 form a unified whole hinged on one end of single-acting connecting rod 4 and double-acting connecting rod 5, and the other end of automatic connecting rod 6 and single-double acting connecting rod 7 is hinged on the fixed table , the above-mentioned parts form a parallelogram luffing mechanism, and the piston cylinder of the cylinder 8 is integrally hinged with the fixed table 9, the upper mold 10 and the lower mold 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com