Method and system for washing corn starch by reduced swirler separation

A technology of cyclone separation and corn starch, which is applied in the field of corn starch separation protein and washing process, can solve the problems of high energy consumption and long time consumption, and achieve the effect of reducing energy consumption and step time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

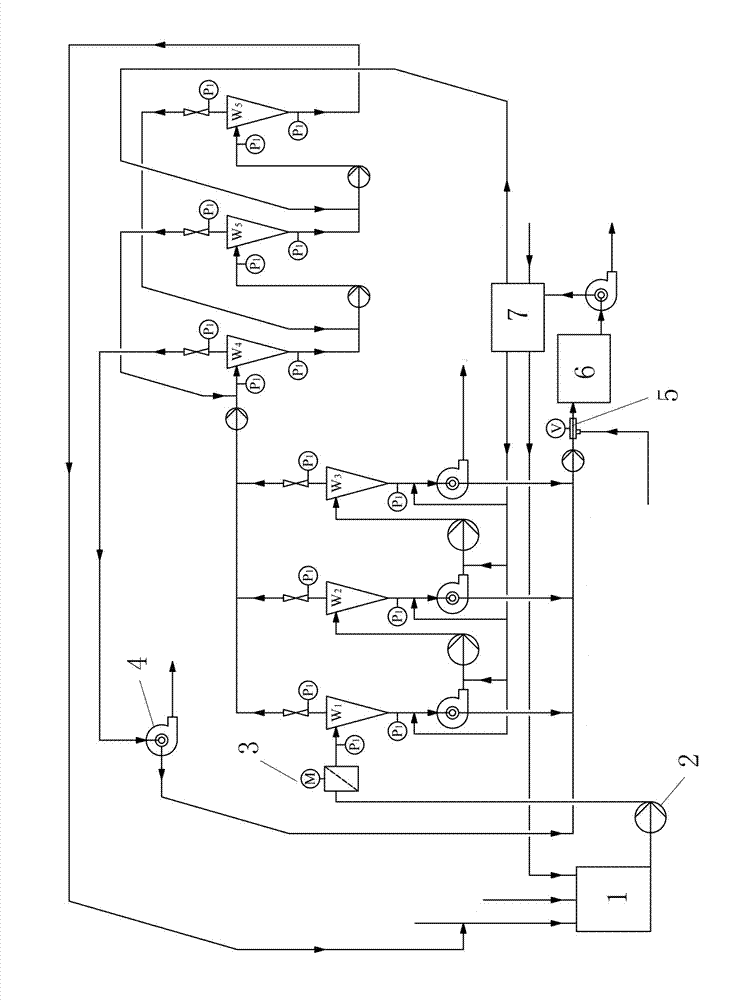

[0034] Method of the present invention comprises the steps:

[0035] Step 1: After adjusting the Baume concentration of coarse starch milk in the total storage tank to 30-34°Bx / 45°C, pressurize it with the starch cyclone pump and enter the cyclone separator W1;

[0036] Step 2: Top flow mixture from cyclone W1 Ti The top flow concentration is 4-8°Bx, the mass percentage of protein dry basis is 40% to 50%, the content of starch dry basis is 50% to 60%, and the top flow mixture Ti Top flow mixture with cyclone W2 TII , top flow mixed liquid of cyclone separator W3 TIII After confluence, after mixing, it enters the cyclone separator W4, the cyclone separator W5 and the cyclone separator W6; Ti >Top flow mixture TII >Top flow mixture TIII , top flow mixture TIII The protein dry basis mass percentage content is 22%.

[0037] Step 3: Underflow mixture from cyclone W1 BI For, the underflow concentration is 40-42°Bx, the mass percentage of protein dry basis is 0.4%-1%, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap