Automatic ultrasonic flaw-detecting machine for tray type large shell section parts

A large-scale cylinder and tray-type technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems that affect the reliability and accuracy of workpiece flaw detection, manual flaw detection workers have high labor intensity, and affect production progress and production efficiency. Achieve the effects of eliminating adverse effects, improving product safety and quality, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with the accompanying drawings and embodiments as follows.

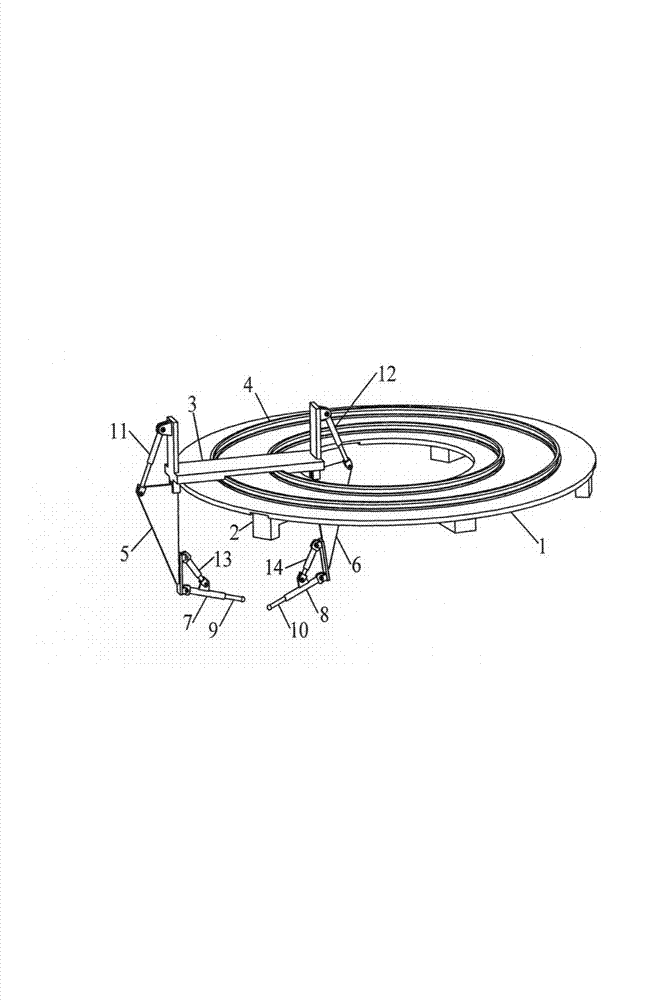

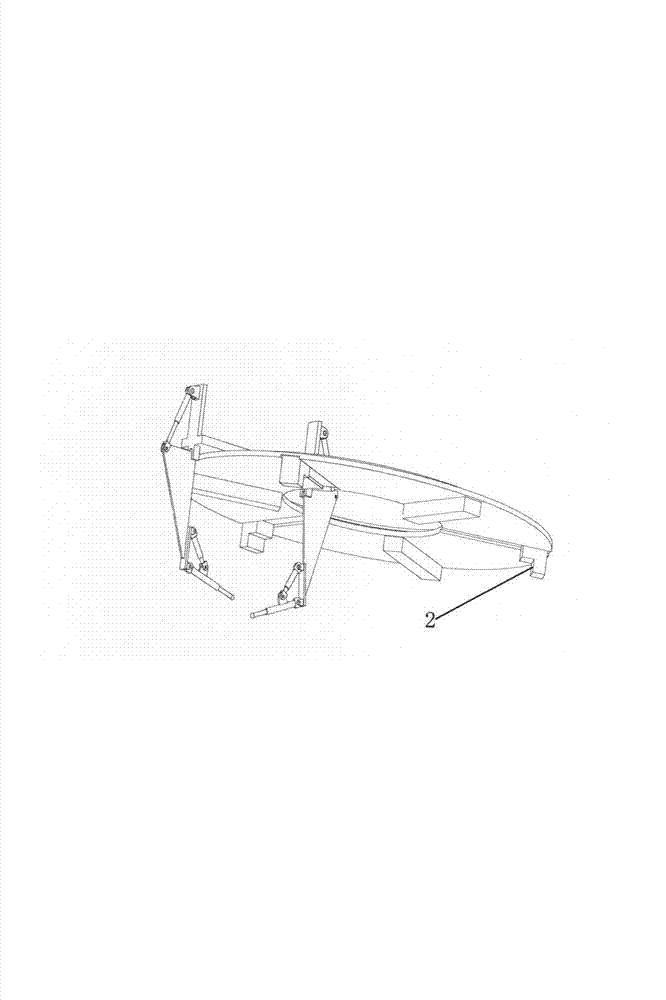

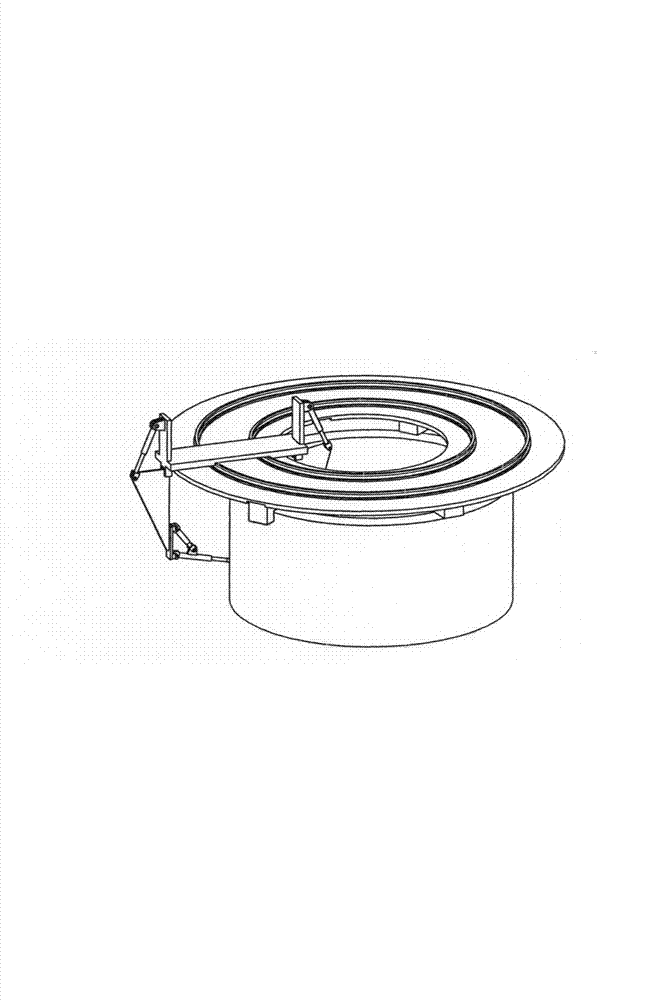

[0016] Such as figure 1 As shown, the pallet-type large-scale ultrasonic automatic flaw detection machine for tubular parts in the present invention consists of a ring-shaped tray 1, a three-jaw chuck 2, a track traveling trolley 3, a ring-shaped guide rail 4, and an outer large rotating arm 5 , Inner boom 6, Outer detection arm 7, Inner detection arm 8, Outer telescopic rod and probe 9, Inner telescopic rod and probe 10, Outer boom driving cylinder 11, Inner boom driving cylinder 12, Outer Detect forearm drive cylinder 13 and inner detection forearm drive cylinder 14.

[0017] The ring-shaped tray 1 is the support of the whole machine. The lower surface of the tray 1 is fixedly connected with the three-jaw chuck 2. The three-jaw chuck 2 is evenly distributed along the circumferential direction of the tray 1. The three jaws form a central angle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com