Slow-release pesticide granule

A technology for slow-release pesticides and granules, applied in the field of pesticides, can solve the problems of not complying with energy saving and environmental protection, difficult to industrialize production, consume large heat energy, etc., and achieve the effects of improving the first pass rate, low cost and abundant resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

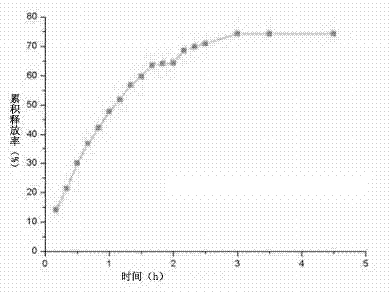

[0031] Preparation of 2% imidacloprid sustained-release pesticide granules

[0032] (1) Put 20.84kg of 96% imidacloprid granules, 20kg of methylcellulose, 30kg of hydroxypropylcellulose, 10kg of sodium dodecylbenzenesulfonate, 15kg of p-methylsulfonyl chloride, and 904.16kg of general clay into the double-helix mixer After stirring in the mixer for 20 minutes, pulverize.

[0033] (2) Slowly feed the product of (1) into the rotating disc granulator through the screw conveying system. Insert the steam pipe into the material while feeding, and let the steam flow while feeding, and turn the disc to granulate. When the granulation is completed, turn off the steam, and continue to rotate the disc granulator for 10-30 minutes, so that the particles in the disc can increase the hardness by rolling.

[0034] (3) Dry the product in (2) with hot air through a drum dryer.

[0035] (4) The product dried in (3) is cooled by air through a drum cooler.

[0036] (5) Sieve the cooled produc...

Embodiment 2

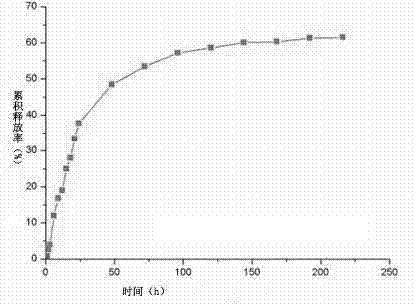

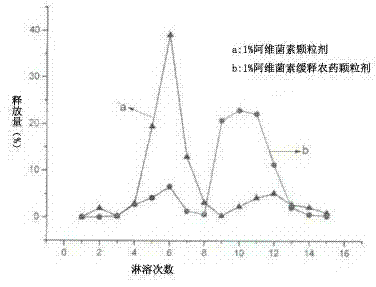

[0038] Preparation of 1% Abamectin Sustained Release Pesticide Granules

[0039] (1) Put 11.12kg of 90% Abamectin powder, 80kg of hydroxyethyl cellulose, 50kg of sodium lauryl sulfate, 10kg of p-toluenesulfonic acid, 10kg of acrylic acid, and 839kg of clay into the double-screw mixer The mixture was mixed for 30 minutes and pulverized.

[0040] (2) Slowly add the product of (2) into the rotating disc granulator through the belt conveyor, and add the product of (1) into the rotating disc granulator with heating function (the bottom can be heated by the electric disk), Spray water and heat while feeding, and the heating temperature is controlled at 65-100°C. Stop spraying water and heating after the material in the disc is basically completely granulated, and then turn the disc for 10-30 minutes.

[0041] (3) Dry the product of (2) with hot air through a drum dryer.

[0042] (4) Turn the dried material in (3) to a blower cooler for cooling.

[0043] (5) Sieve the cooled produc...

Embodiment 3

[0045] Preparation of 20% Chlorpyrifos Slow-release Pesticide Granules

[0046] (1) Add 222.3kg of 90% chlorpyrifos stock solution to 150kg of white carbon black for full adsorption, then add 100kg of hydroxypropyl methylcellulose, 20kg of calcium dodecylbenzenesulfonate, 30kg of p-toluenesulfonic acid, and 477.7kg of clay into the After stirring in a twin-screw mixer for 20 minutes, it was pulverized.

[0047] (2) Slowly add the product of (1) into the rotating disc granulator through the screw feeder, and at the same time insert the steam pipe into the material in the disc, and pass steam while feeding until the material in the disc is basically To granulate, turn the disc for another 10-30 minutes.

[0048] (3) Dry the product in (2) with hot air through a drum dryer.

[0049] (4) Cool the dried product in (3) through a drum cooler.

[0050] (5) Sieve the cooling material in (4) with a rolling grading sieve, return the unqualified part to step (1) for crushing, and pack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com