Fixing bracket system with stress groove

A technology for fixing brackets and stress grooves, applied in the direction of fixers, internal bone synthesis, and external plates, can solve problems such as poor healing quality, affect blood supply at both ends of the fracture, prolong healing time, etc., and achieve high healing quality and blood supply. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

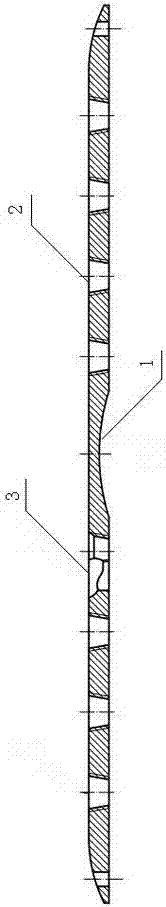

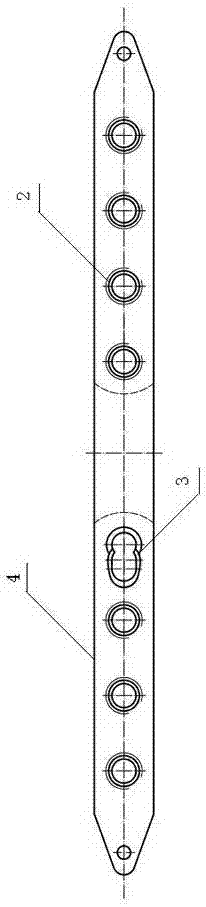

[0014] Embodiment 1, a kind of stress groove internal fixation support system, refer to figure 1 , figure 2 As shown, the system is composed of a main structure 4, seven locking holes 2, a locking pressure hole 3 and a stress groove area 1; the main structure 4 is a shuttle-shaped elongated alloy plate, the middle part of which is close to the side of the bone, The main structure presents a concave arc shape, and its concave height is 0.3mm-0.5mm, which is the stress groove area 1; the locking hole 2 and the locking pressure hole 3 are evenly distributed on both sides of the main structure except the stress groove area. plate.

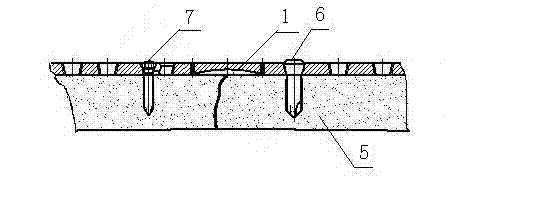

[0015] During use, such as image 3 , Figure 4 As shown, through the locking hole 2, the end of the locking bone screw 6 uses locking screws to fix the internal fixation bracket system on the bone; the pressure bone screw 7 enters the bone through the locking pressure hole 3, so that the bracket system is fixed on the different fractures of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com