Washing machine spin shaft forming process and forming dies thereof

A molding process, dewatering shaft technology, applied in the direction of metal extrusion dies, etc., to achieve the effect of high precision and surface roughness of parts, high production efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

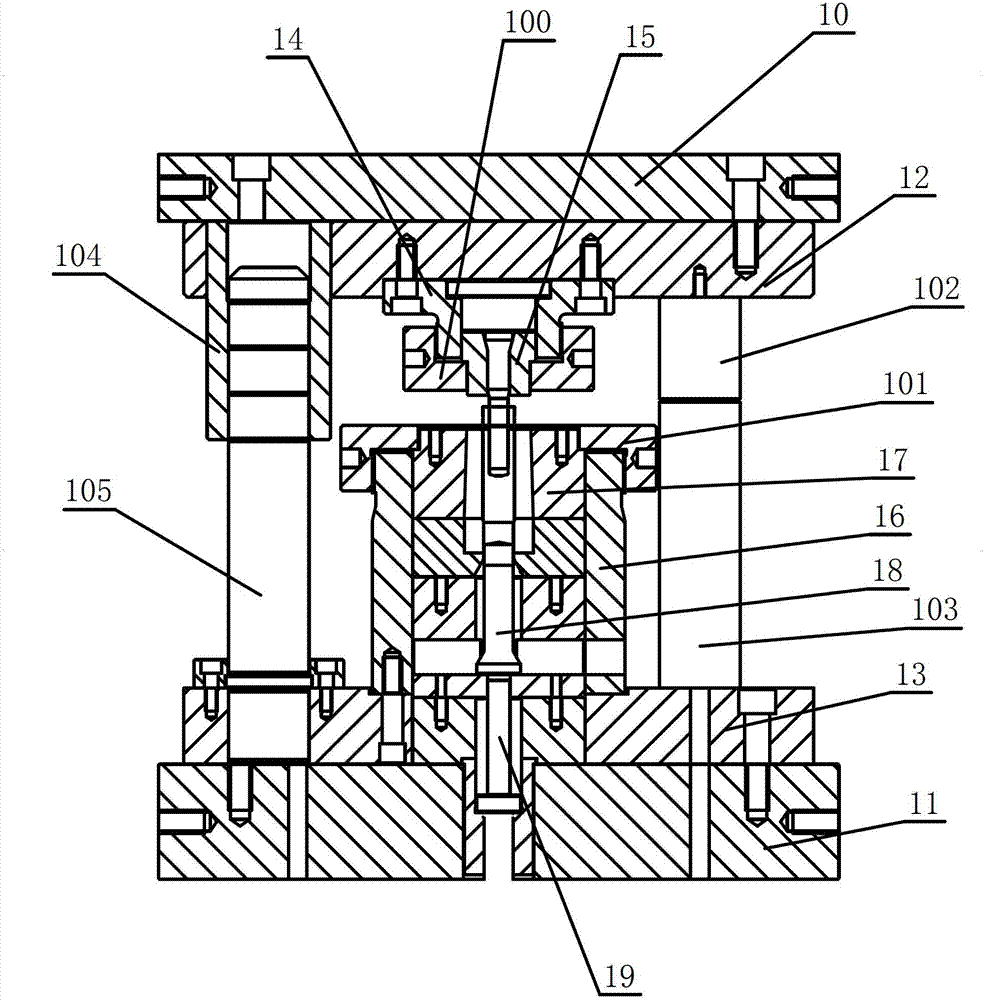

[0034] See figure 1 As shown, in this embodiment, a washing machine dehydration shaft squeezing mold includes an upper mold plate 10 and a lower mold plate 11. An upper mold base 12 is fixed below the upper mold plate 10, and a lower mold base 13 is fixed above the lower mold plate 11. , A guide assembly and a limit assembly are provided between the upper mold base 12 and the lower mold base 13, the guide assembly includes a guide sleeve 104 and a guide post 105, the guide sleeve 104 is arranged on the upper mold base 12, so The guide post 105 is disposed on the lower mold base 13 corresponding to the guide sleeve 104. The limit component includes an upper limit post 102 fixed below the upper mold base 12 and a lower limit post 103 fixed above the lower mold base 13. The upper mold base 14 is fixed below the upper mold base 12, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap