Pneumatic bending press and bending method

A buckling machine and pneumatic technology, applied in the field of buckling, can solve the problems of large equipment volume, hydraulic oil pollution, limited forming times, etc., and achieve the effects of small equipment volume, energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

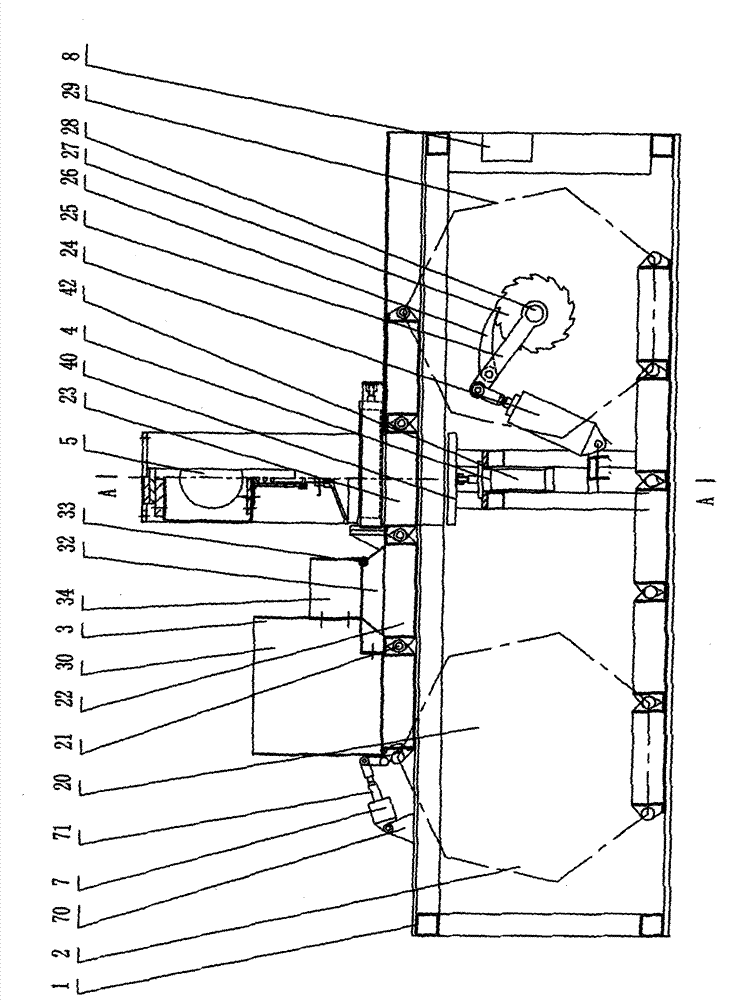

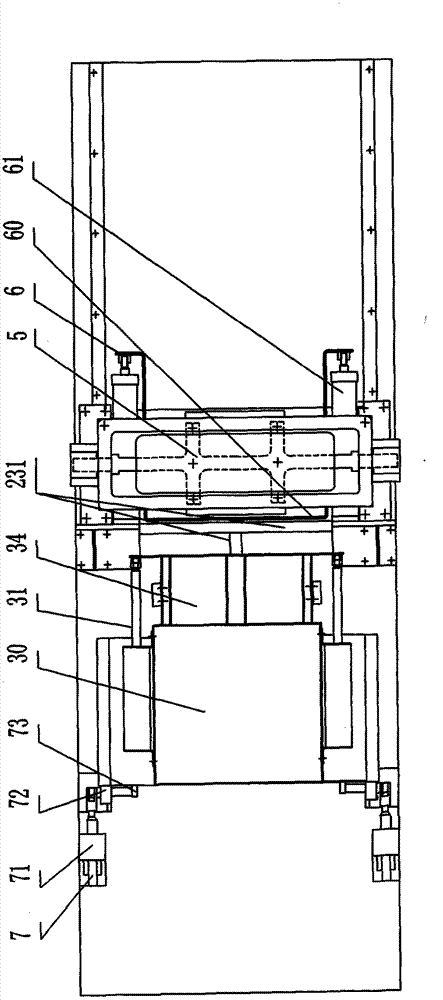

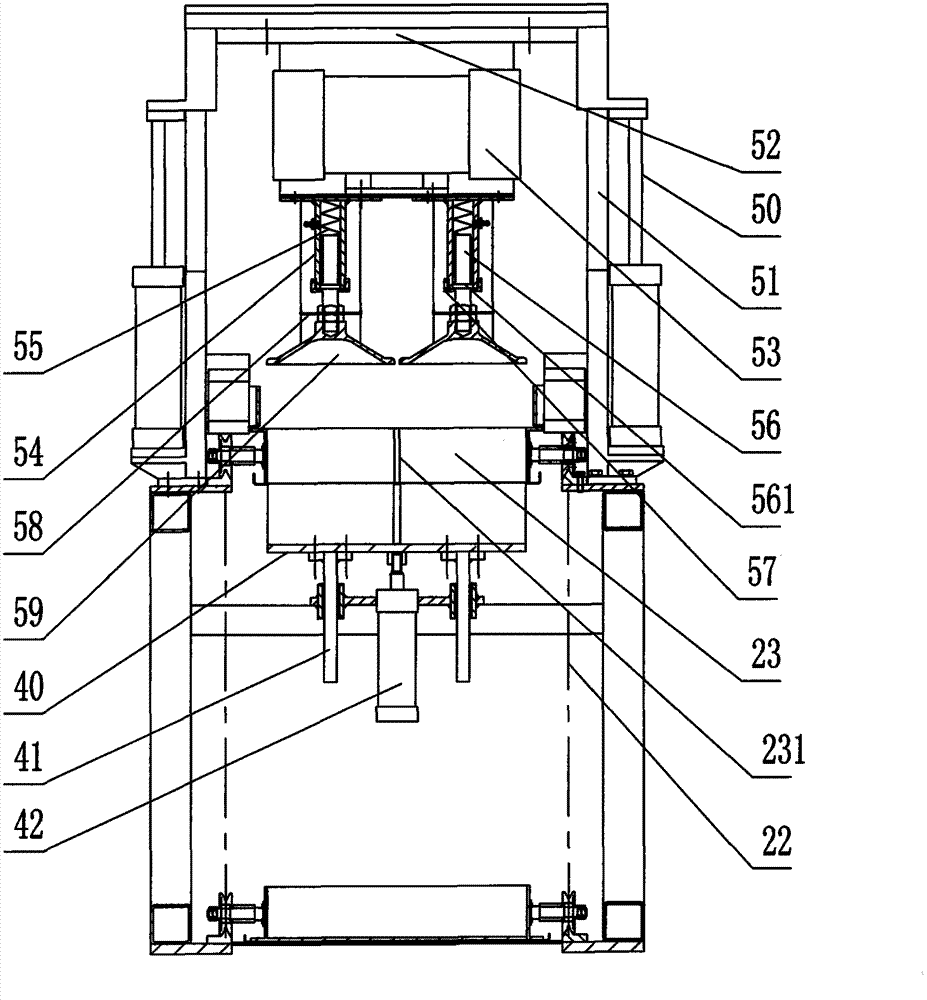

[0014] The pneumatic bending machine includes a frame 1, a chain transmission device 2 arranged on the frame 1, a profiling device 5, a feeding device 3, an ejecting device 4 and an output device 6, and the feeding device 3 includes a primary feeding box 30, a secondary Feeding box 34, feeding cover 32, feeding cylinder 31 connected to primary feeding box 30 and secondary feeding box 34 at both ends respectively, secondary feeding box 34 can freely enter and exit primary feeding box 30 under the action of feeding cylinder 31; profiling device 5 includes the mold slide rail 51, the mold cylinder 50 and the mold bracket 52 arranged on the frame 1, the mold bracket 52 is slidably matched with the mold slide rail 51, and the mold bracket 52 can be Move along the die slide rail 51; the die support 52 is provided with a vibrating motor 53, two die handle sleeves 54 and two die handles 59; The handle 56 is provided with a boss 561, and the boss 561 is slidingly matched with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com