Weft yarn cutting mechanism of warp knitting machine

A technology of cutting mechanism and warp knitting machine, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problems of waste and cutting weft yarns at fixed lengths, and achieve the effects of avoiding waste, saving raw materials, and high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

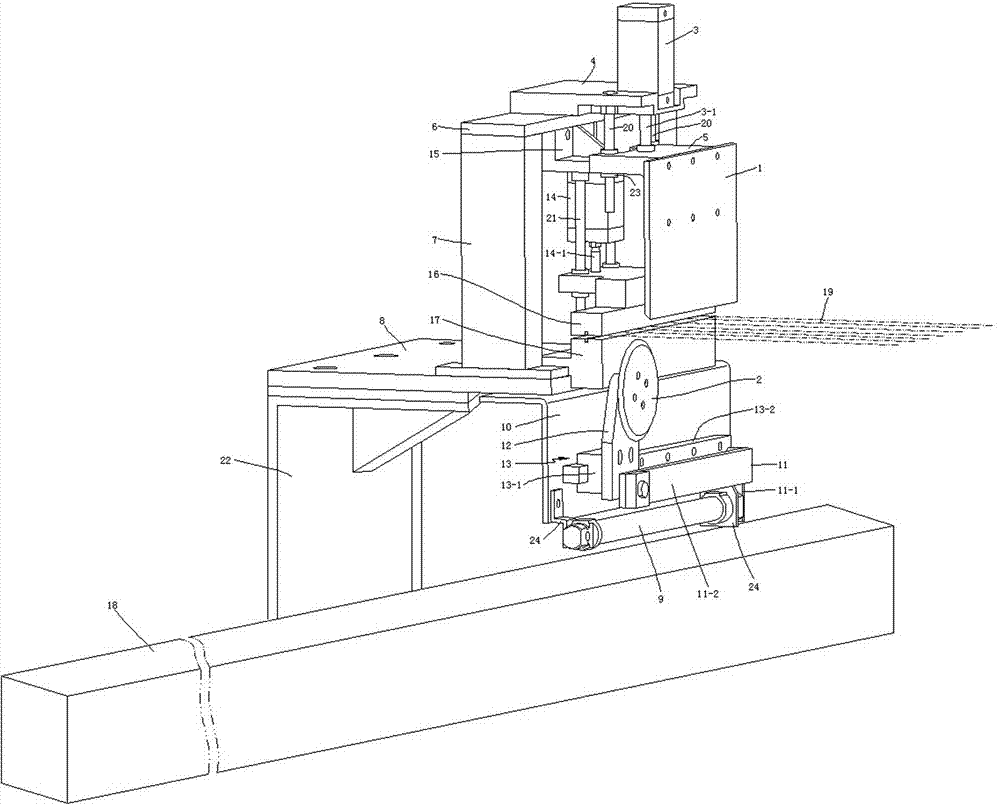

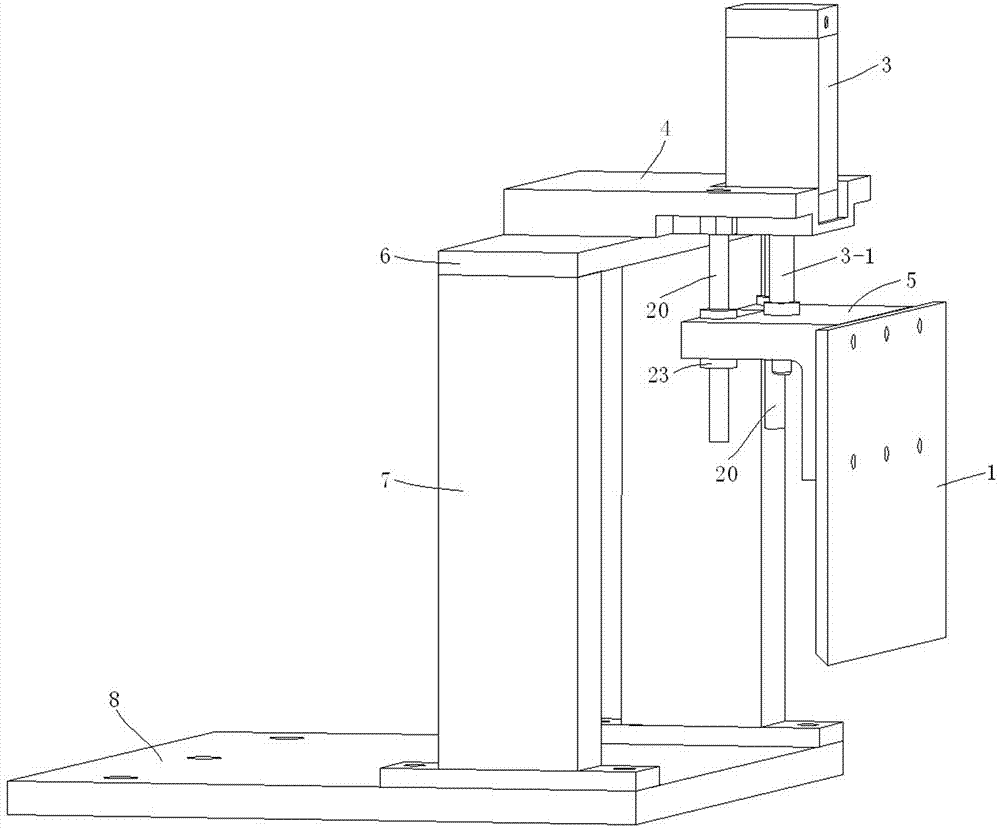

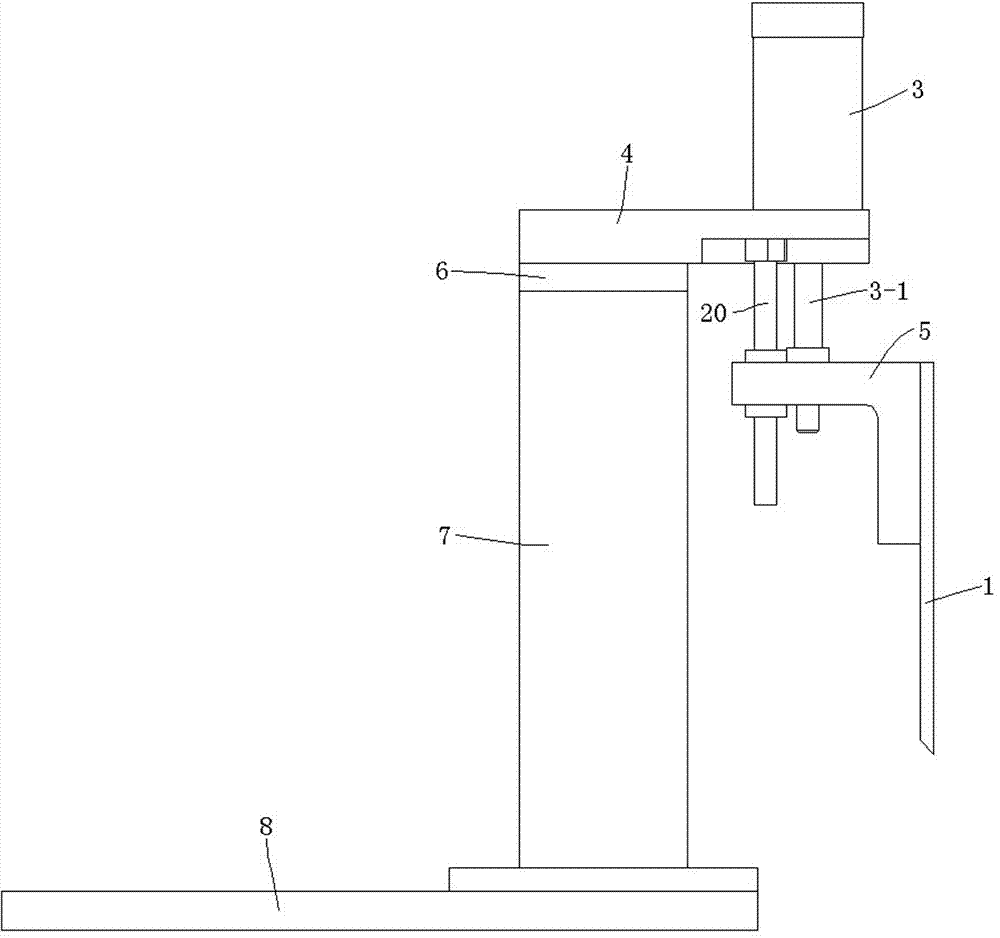

[0022] see Figure 1 to Figure 8 A kind of warp knitting machine weft yarn cutting mechanism shown, comprises upper blade 1 and lower blade 2 arranged up and down for cutting weft yarn, and this cutting mechanism also includes described upper blade 1 along the vertical direction of warp knitting machine to move up and down The reciprocating upper blade up and down reciprocating mechanism, and the lower blade reciprocating and traversing mechanism with the lower blade 2 along the beam guide rail 18 length direction of the warp knitting machine, and the weft yarn creel of the warp knitting machine The weft yarn 19 sent out is clamped by the clamping mechanism between the upper blade 1 and the lower blade 2 . The upper blade 1 of the present invention is preferably made of a rectangular plate, and its bottom surface is provided with a cutting edge. The lower blade 2 is preferably a disc-shaped blade, and its outer peripheral surface is provided with a cutting edge. During work, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com