Method for shaping cylindrical gear

A cylindrical gear and gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as unfavorable CAE analysis, low model quality, unfavorable dimension parameterization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0039] The following table shows the basic parameter codes of gears:

[0040] parameter name

parameter code

modulus

m

Number of teeth

z

α

Helix angle

β

Addendum height coefficient

h * a

Headspace coefficient

c *

Modification coefficient

x

tooth width

B

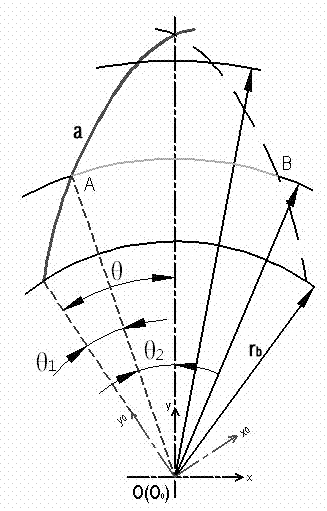

[0041] like figure 1 As shown, the equation of the involute a of the tooth profile is:

[0042]

[0043] Among them, in the shifting gear,

[0044]

[0045] θ 2 =s / 2r

[0046] According to the involute function, take the end face parameters:

[0047] θ 1 =tanα-α

[0048] So you can get:

[0049] θ=θ 1 +θ 2

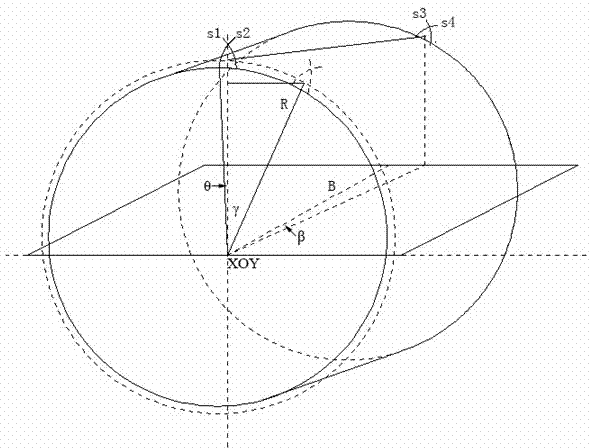

[0050] like image 3 As shown, combined with the helical gear spiral principle, it can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com