A Calculation Method of Bulk Stockpile Shape Parameters in Stockyard

A calculation method and stockpiling technology, applied in the field of calculation of bulk material pile shape parameters in stockyards, can solve problems such as long time, high labor intensity, maximization, etc., and achieve the effects of convenient use, high computational efficiency, and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] A method for calculating the shape parameters of bulk materials in a stockyard, comprising the following steps:

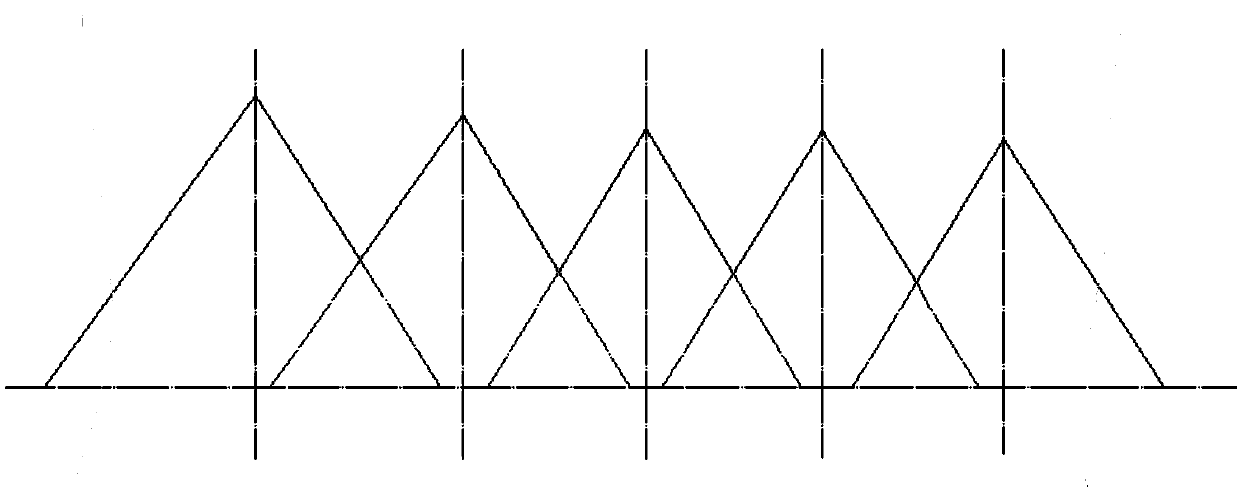

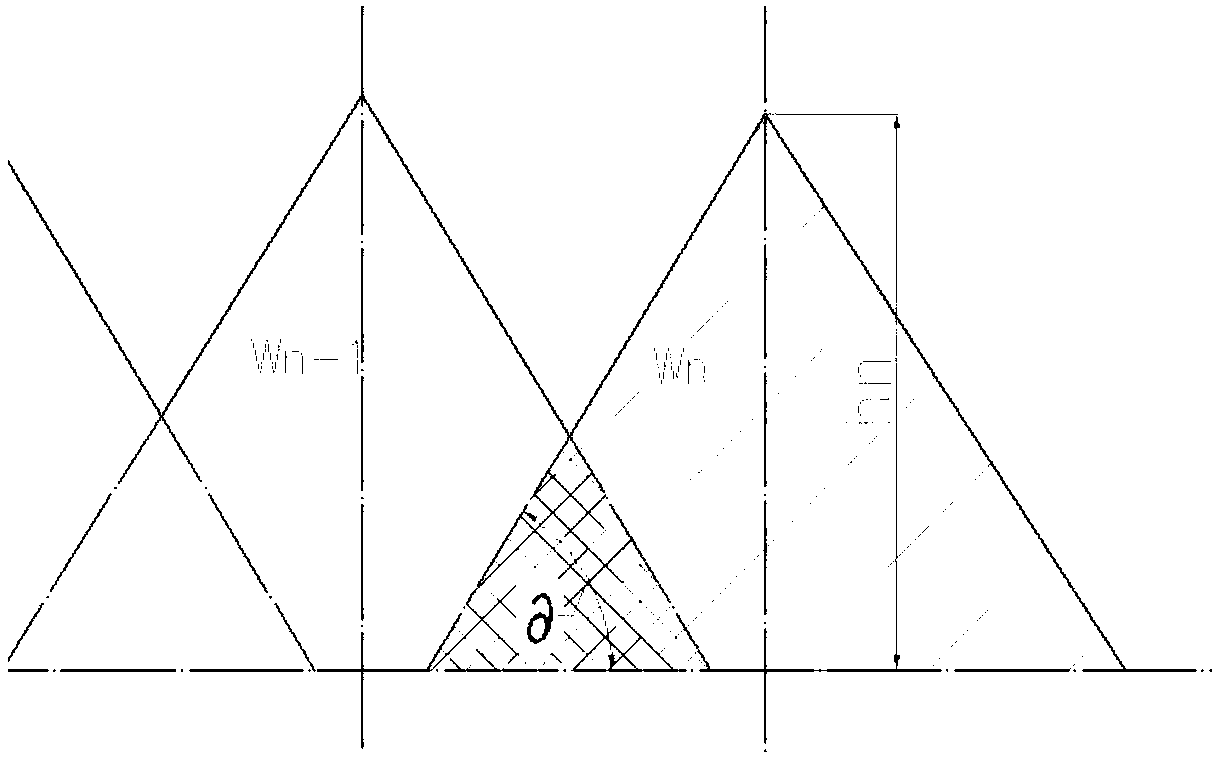

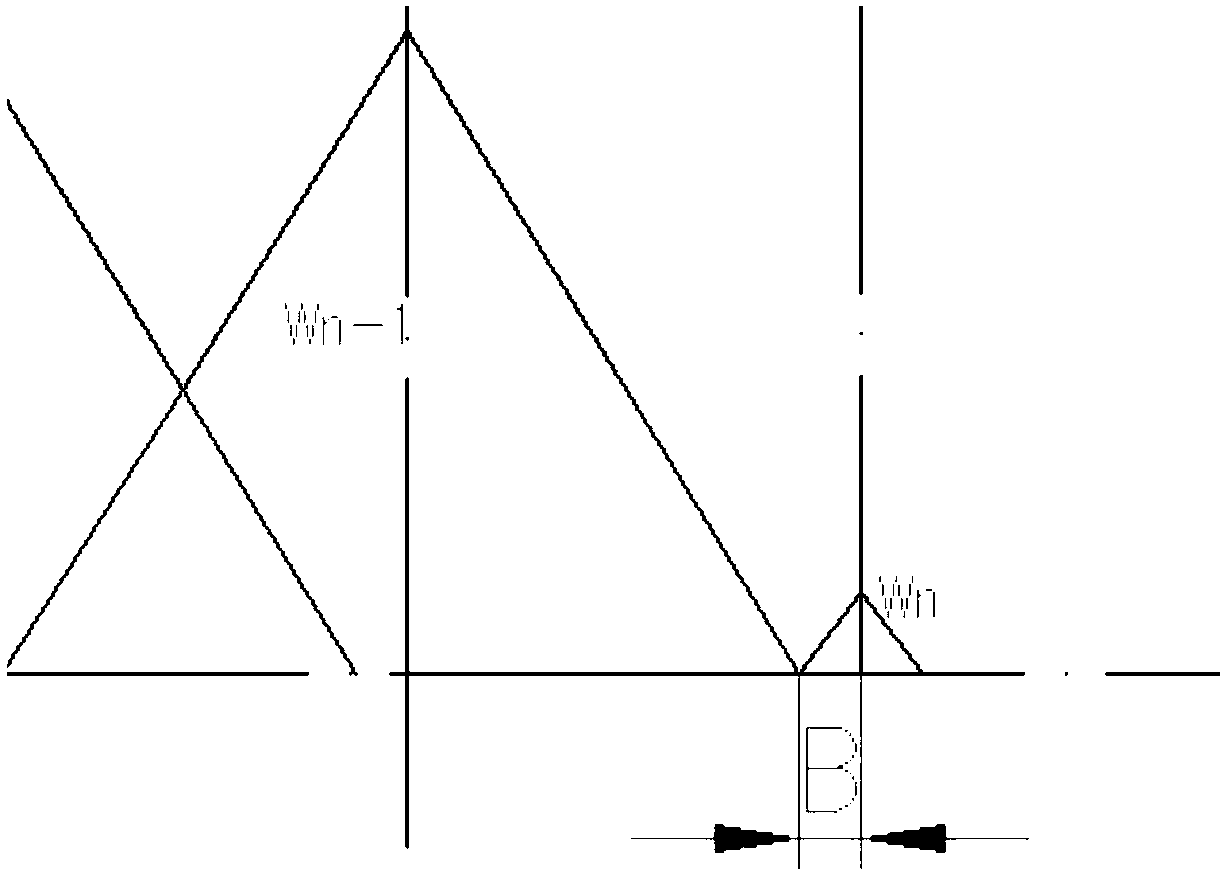

[0037] Step 1. Obtain the angle between the projection line of the material pile surface and the bottom surface of the material pile like figure 2 shown. For a certain bulk material, the shape of the pile formed by the stacker and reclaimer is a cone, such as figure 1 As shown, the test method was used to measure the value, experimentally proven It is a certain value, which is related to the property of the stockpile itself and has nothing to do with the height of the stockpile.

[0038] Step 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com