Fire-resistant liner for warm air pipeline and paving method thereof

A technology of hot air duct and refractory lining, which is applied in lighting and heating equipment, lining repair, lining support, etc. It can solve the problems of inability to play a supporting role, many spare parts for maintenance, and easy oxidation, so as to improve the efficiency of spraying construction, Effect of reducing working time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

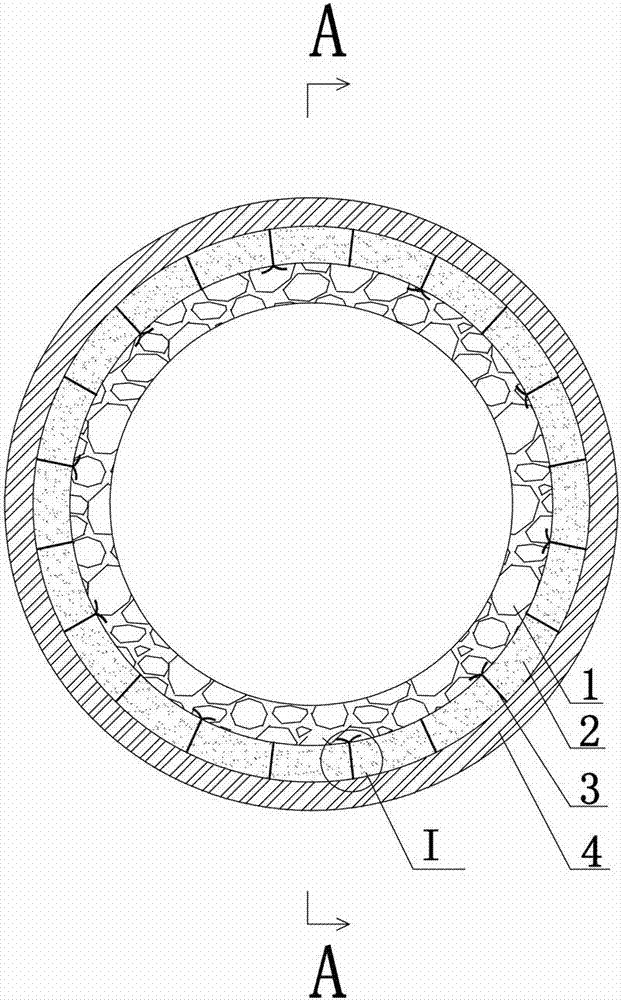

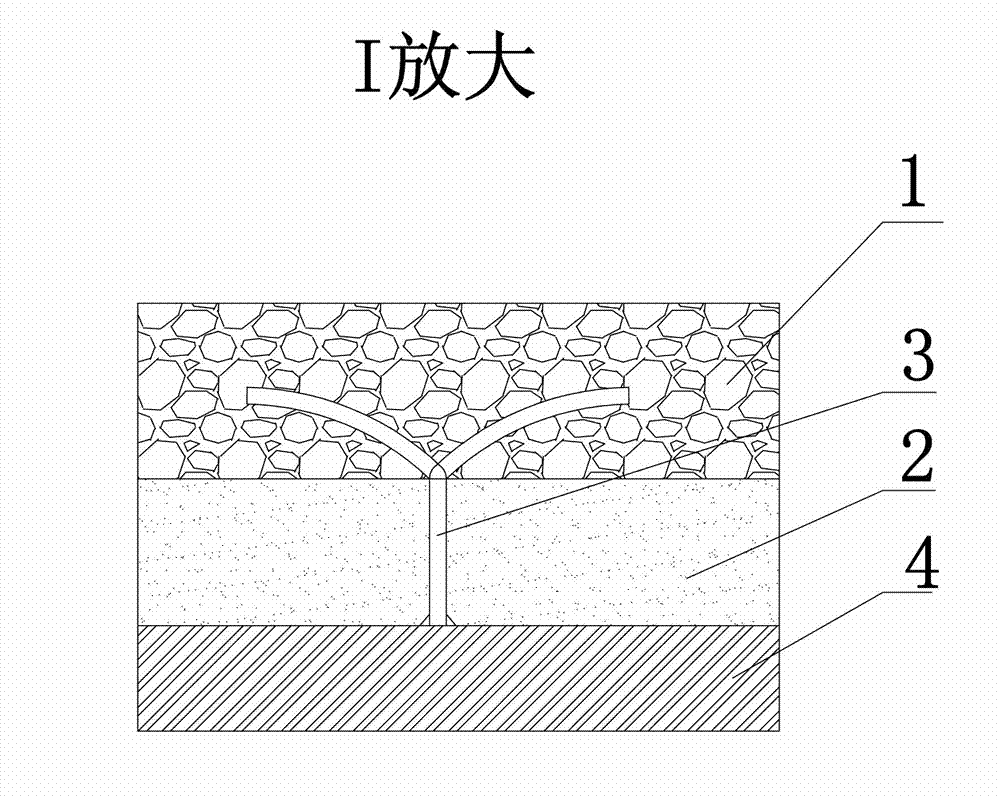

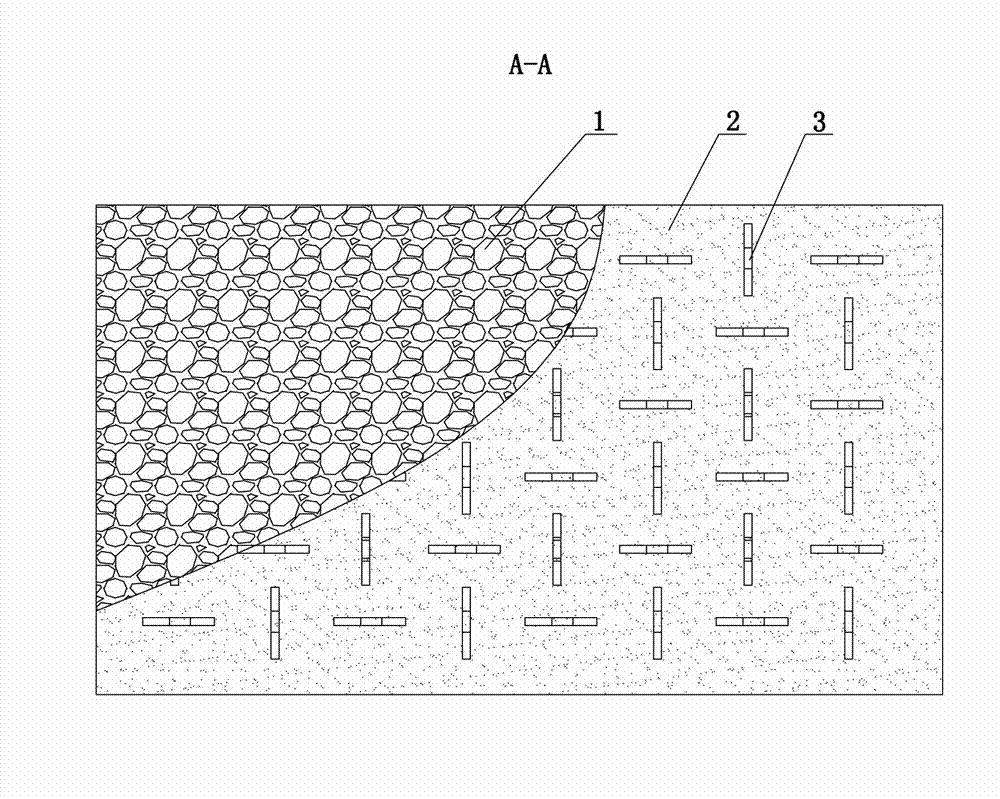

[0018] like figure 1 , 2 and image 3 As shown, a hot blast pipeline refractory lining, including a hot blast pipeline, is characterized in that it includes a set of anchor nails 3 welded on the inner wall 4 of the hot blast pipeline, penetrates this set of anchor nails 3 and abuts on the hot blast pipeline The refractory fiber mat 2 of the inner wall 4 is sprayed on the spray coating 1 on the surface of the refractory fiber mat 2, the upper part of the anchor nail 3 is a double-headed end that abuts against each other, and the lower part is a single-headed end, and the single-headed end is connected to the The inner wall 4 of the hot air duct is welded together, and the double ends of the upper part of the anchor nail 3 are separated and pressed against the surface of the refractory fiber felt 2 .

[0019] The separation direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com