Anti-corrosion layer spraying device for inner wall of large tank body

A spraying device and technology inside the tank, which is applied in the field of anti-corrosion layer spraying devices on the inner wall of large tanks, can solve the problems of easy peeling off of the anti-corrosion layer and low degree of process automation, and achieve the effects of reducing quantity, realizing intelligent control and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

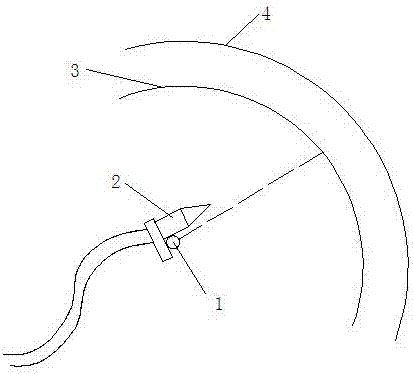

[0030] The embodiments are given below in conjunction with the drawings and the present invention will be described in detail. It is necessary to point out that the following examples are only used to further illustrate the present invention and cannot be understood as limiting the scope of protection of the present invention. Professionals in this field make some non-essential improvements based on the content of the present invention. And adjustments still belong to the protection scope of the present invention.

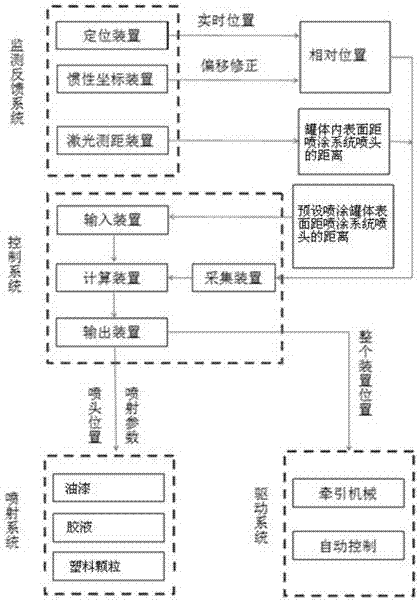

[0031] The invention discloses a spraying device for an anticorrosive coating on the inner wall of a large tank, which comprises a control system, a monitoring feedback system, a spraying system, a liquid supply system and a driving system. Input the preset lining section parameters and spraying material parameters into the control system, and the system can run automatically to form a complete lining through spraying construction.

[0032] The control system includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com