Forming method for anticorrosion layer of inner wall in large tank

A molding method and technology inside the tank, applied to the coating, the device for coating liquid on the surface, the spraying device, etc., can solve the problems of low process automation and easy peeling off of the anti-corrosion layer, and achieve intelligent control and reduce The effect of high quantity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments are given below in conjunction with the accompanying drawings and the present invention is described in detail. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the content of the present invention above And adjustments still belong to the protection scope of the present invention.

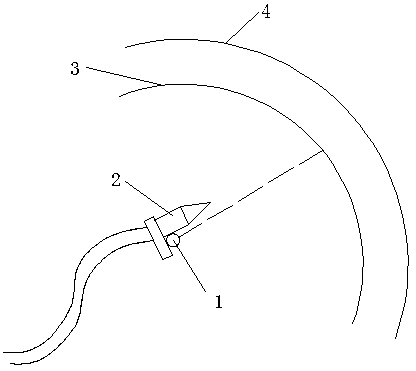

[0033] Drive the anti-corrosion layer spraying device according to the present invention into the axis position in the tank to be constructed, and set up the inertial coordinate device.

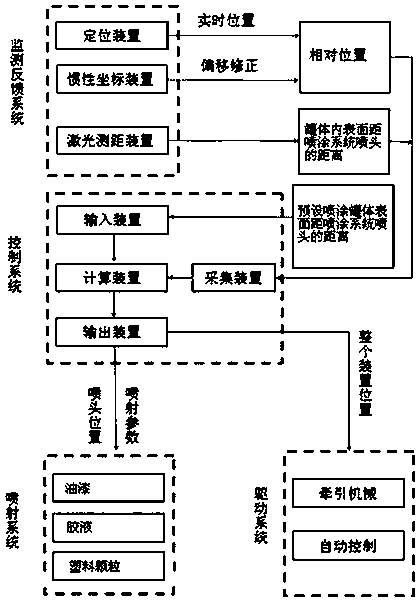

[0034] Such as figure 1 As shown, the first step is to input the parameters of the inner surface of the tank after spraying and the parameters of the spraying material into the control system, for example, the radius of the inner wall of the tank is 8m, the spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com