Spraying structure and spraying device with the spraying structure

A technology of spraying device and mixed structure, applied in spraying device, liquid spraying device, building structure and other directions, can solve the problems of low construction efficiency, inability to spray paint, long spraying construction time, etc., to improve efficiency, reduce workload and effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

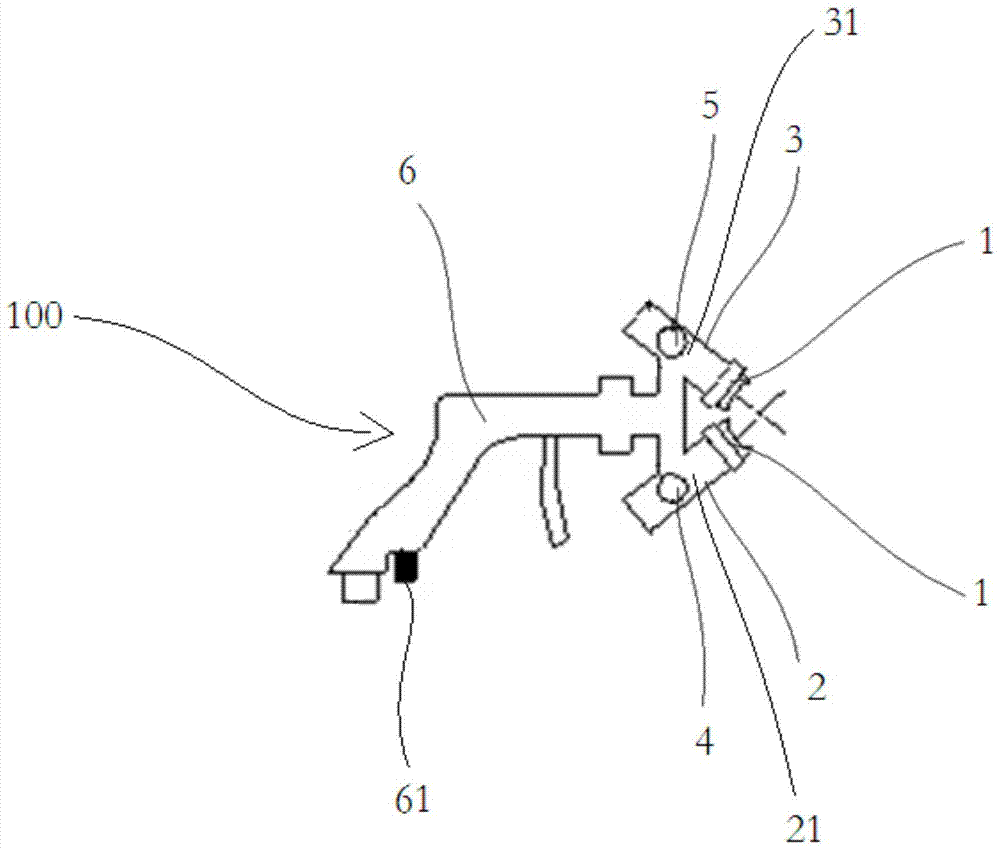

[0049] refer to figure 1 , an injection structure 100 of the present invention, comprising

[0050] Nozzle 1,

[0051] a mixing structure, connected to the nozzle 1, for mixing at least the first material and the second material before and after the nozzle 1; and

[0052] The conveying structure transports each material to the mixing structure respectively.

[0053] The spraying structure of the present invention is applied to the spraying of buildings, and the first material and the second material are respectively transported to the mixing structure through the conveying structure, and the first material and the second material are mixed by the mixing structure and passed through the mixing structure. The nozzle 1 is used to spray the mixture of the first material and the second material onto the surface of the object to be sprayed. It realizes the mixing of the first material and the second material after entering the spraying structure, avoiding the need to use other de...

Embodiment 2

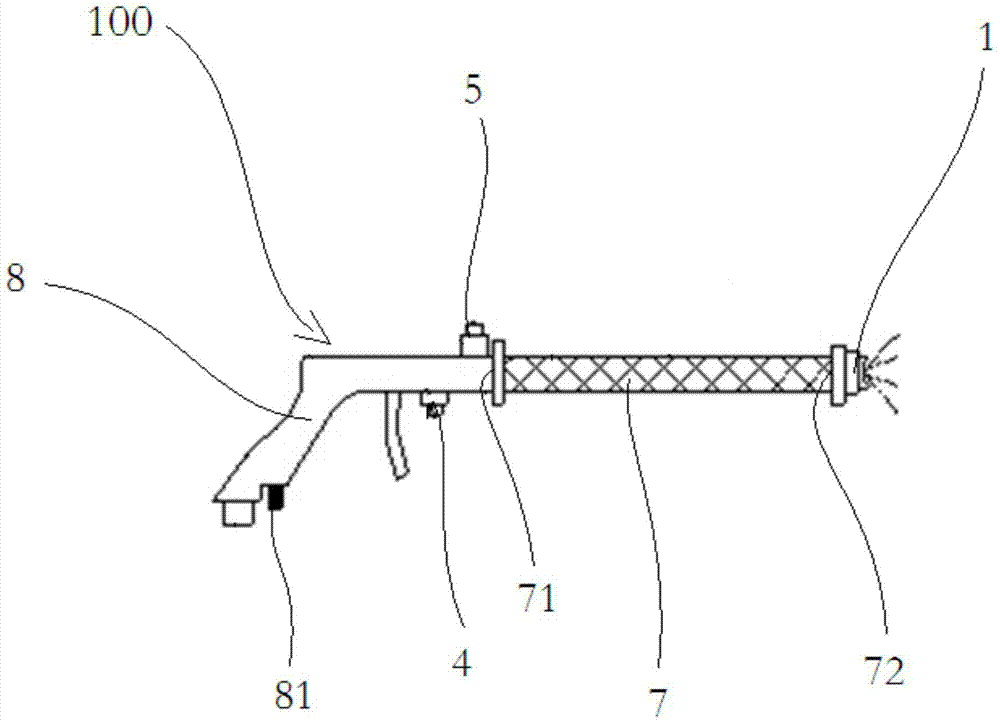

[0066] refer to figure 2 , the injection structure of this embodiment is substantially the same as the injection structure of Embodiment 1, the difference is that the specific form of the mixing structure and the atomization device is different, in this embodiment:

[0067] The mixing structure includes a mixing chamber 7, the inlet port 71 of the mixing chamber 7 communicates with the powder delivery pipe 4 for delivering the powder in the delivery structure and the liquid delivery pipe 5 for delivering the liquid, the mixing The outlet port 72 of the chamber 7 communicates with said nozzle 1 .

[0068] The paint powder and water enter into the mixing chamber 7 through the powder conveying pipe 4 and the liquid conveying pipe 5 respectively through the inlet port 71 of the mixing chamber 7, and the mixing chamber 7 feeds the paint powder The paint powder is mixed with water, and the mixed paint powder and water are atomized by the compressed gas and sprayed from the nozzle ...

Embodiment 3

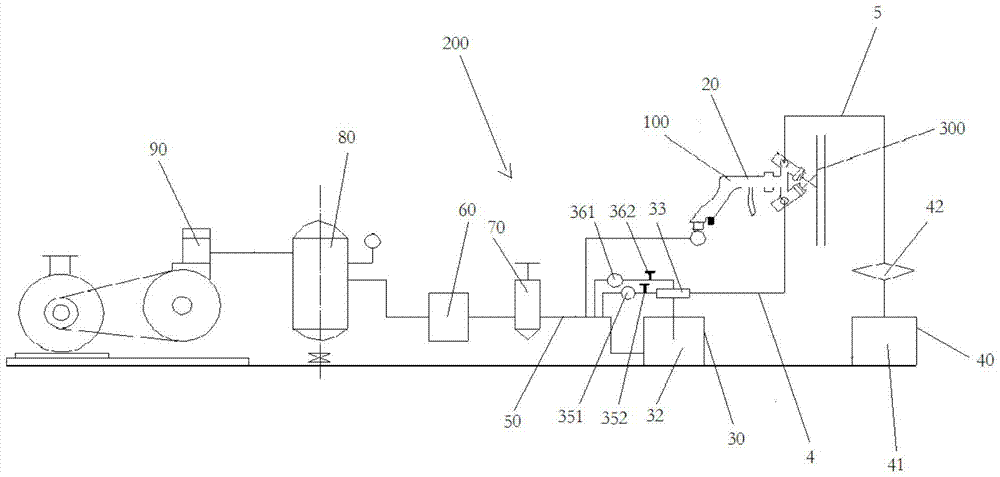

[0073] refer to image 3 , a spraying device 200 of the present invention, comprising

[0074] spray gun 20;

[0075] A material supply device for supplying materials to the spray gun 100;

[0076] The spray gun 20 includes the spray structure 100 described in Embodiment 1, and the material supply device is connected with the conveying structure.

[0077] The spraying device of the present invention is applied to the spraying of buildings, and the first material and the second material are respectively transported to the mixing structure through the conveying structure, and the first material and the second material are mixed by the mixing structure and passed through the mixing structure The nozzle 1 is used to spray the mixture of the first material and the second material onto the surface of the object to be sprayed. It realizes the mixing of the first material and the second material after entering the spraying structure, avoiding the need to use other devices to mix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com