Stress monitoring-based fiber/polymer interfacial shear crystallization on-line detector

A polymer and detector technology, applied in the field of detectors, can solve the problems that the fiber pulling speed cannot be precisely controlled, does not conform to isothermal crystallization, and is incapable of power, and achieves the effects of compact structure, accurate and stable control, and rapid conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

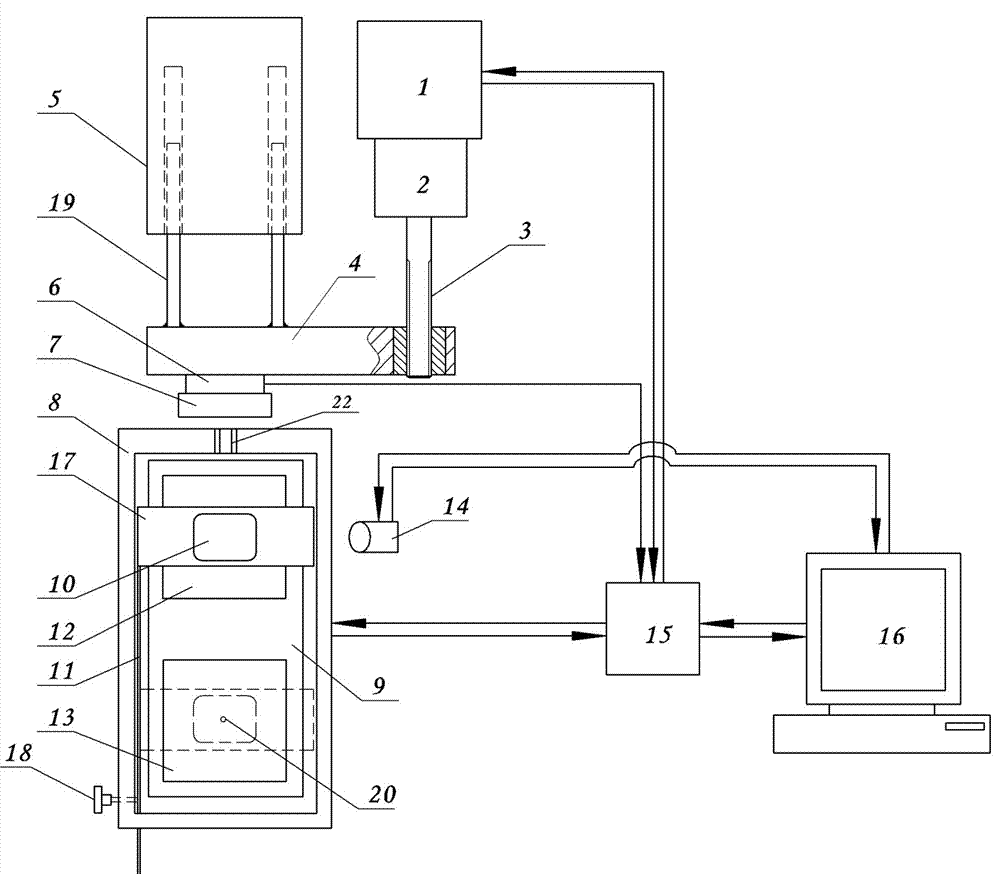

[0028] Embodiment 1: An on-line detector for shear-induced crystallization at the interface of fiber / polymer composite materials, including a double-heating stage, a controllable traction mechanism, a force sensor, a polarizing microscope, a control box, a computer, and the like. The temperature of the sample is controlled by the double heating stage, the controllable traction mechanism pulls the fiber to apply shearing action, the force sensor detects the interaction force between the fiber and the polymer melt during the traction process, and transmits it to the control box and processed by the computer, polarizing microscope Observe the change of crystal morphology.

[0029] The main components are introduced in detail below.

[0030] see figure 1 , the online detector includes a controllable traction mechanism, a double heating stage 8, a polarizing microscope 14, a control box 15 (integrated control device for the heating stage, stepping motor and sensor), a computer 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com