Board housing case for vehicle-mounted electronic device

A technology for in-vehicle electronics and storage baskets, which is applied to electrical equipment shells/cabinets/drawers, electrical components, electrical equipment structural parts, etc. Divergence and other issues, to achieve the effect of averaging, heat dissipation, and stable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

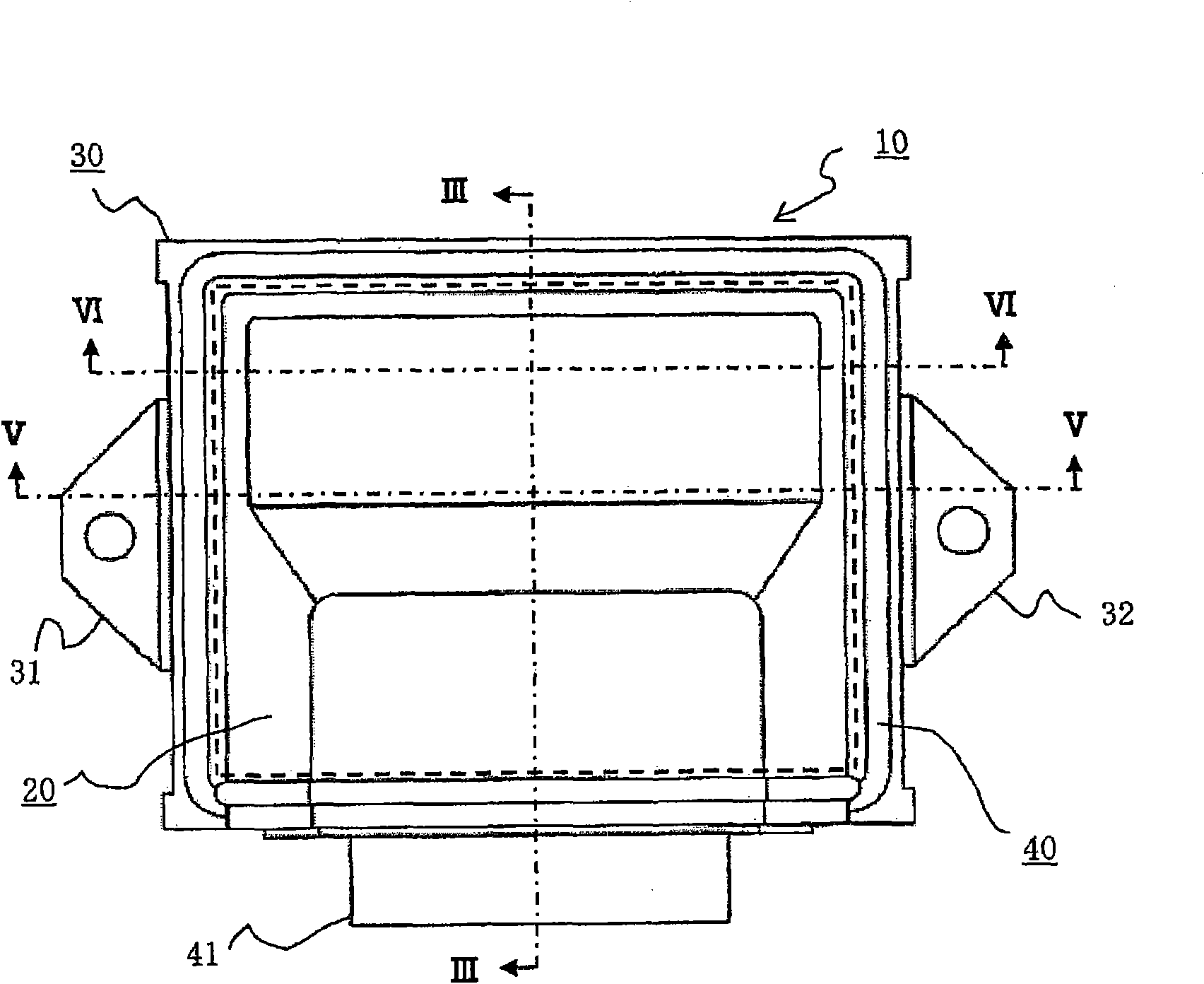

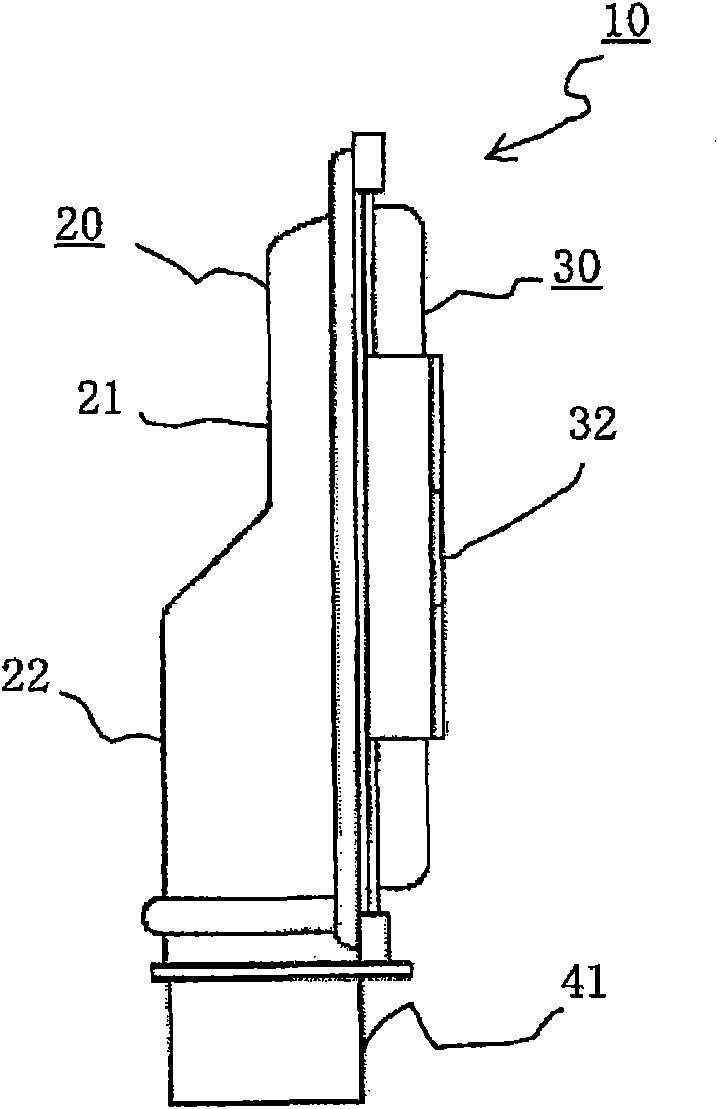

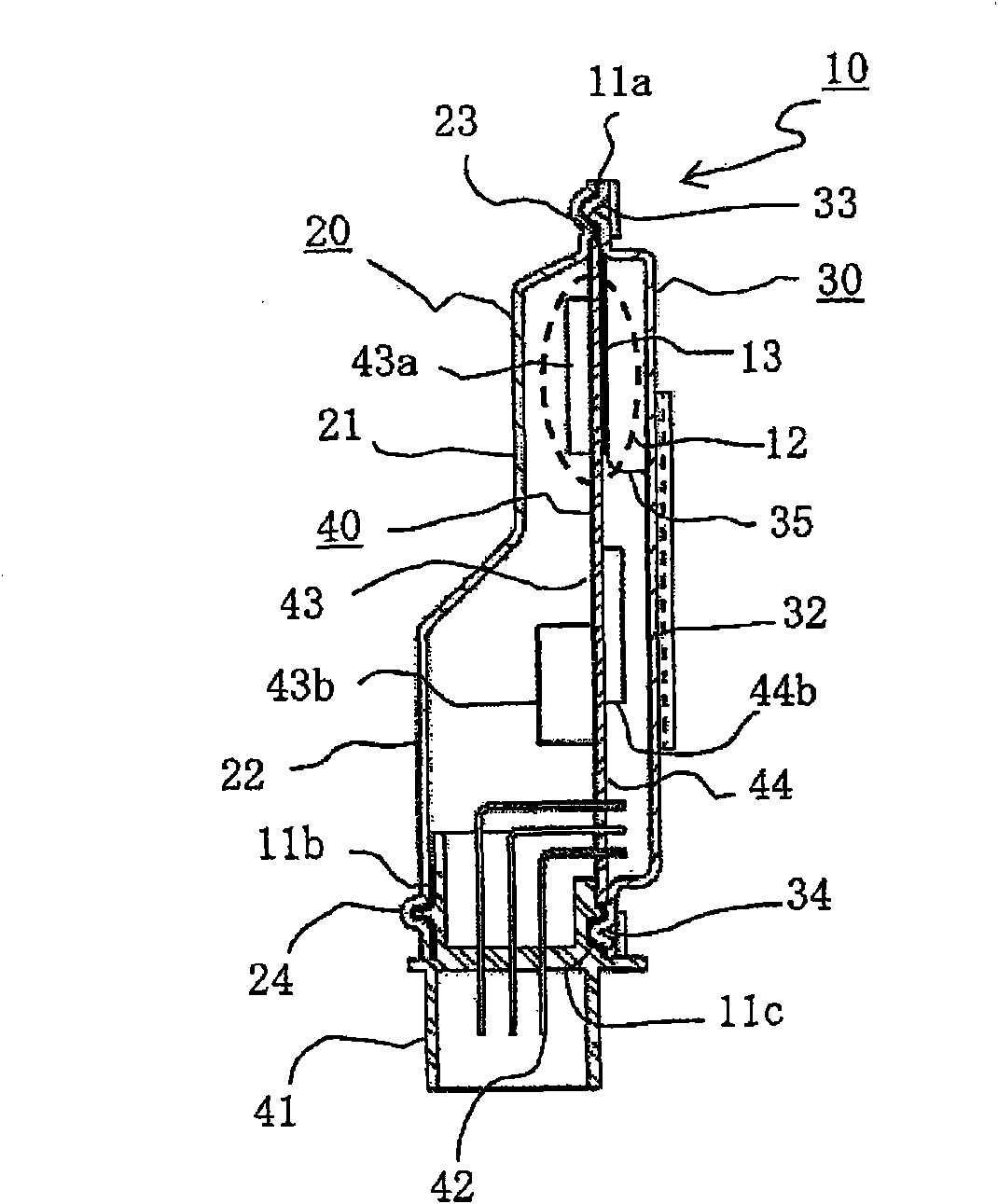

[0096] Hereinafter, the plan view of the substrate housing case of the vehicle-mounted electronic device according to Embodiment 1 of the present invention will be described in order. figure 1 , figure 1 The right side view of the board storage case of the in-vehicle electronic device is figure 2 , figure 1 The sectional view taken along line III-III of the substrate storage case of the vehicle-mounted electronic device is image 3 , figure 1 The bottom view of the substrate storage case of the on-board electronic device is Figure 4 , figure 1 The cross-sectional view of the board storage case of the vehicle-mounted electronic device taken along line V-V is Figure 5 , figure 1 The sectional view of the VI-VI line of the board storage case of the vehicle-mounted electronic device is Figure 6 and figure 1 The external view of a single part of the cover in the substrate storage case of the vehicle-mounted electronic device is Figure 7 Although detailed description w...

Embodiment approach 2

[0154] Hereinafter, a cross-sectional view of the heat transfer mechanism 12A of the substrate housing case of the vehicle-mounted electronic device according to Embodiment 2 of the present invention is Figure 10 and Figure 11 and top view i.e. Figure 12 and Figure 13 Be explained.

[0155] Figure 11 yes Figure 10 The cross-sectional view taken along line XI-XI in , in each figure, the same symbols indicate the same or corresponding parts.

[0156] In addition, this Embodiment 2 shows the detail of the heat transfer mechanism 12 of Embodiment 1, and other code|symbols refer to the original code|symbol or the code|symbol A is added and identified.

[0157] exist Figure 10 , Figure 11 Among them, on the heat transfer base portion 35A having a plurality of isolation protrusions 36A, 36A, an electronic substrate 40A is arranged via a slit G1 limited by the height dimension of the isolation protrusion 36A, and on the opposite side of the electronic substrate 40A A h...

Embodiment approach 3

[0180] according to Figure 14 Embodiment 3 of the present invention will be described. Figure 14It is a sectional view showing the heat transfer mechanism in the substrate housing case of the in-vehicle electronic device according to Embodiment 3 of the present invention. This Embodiment 3 shows the details of the heat transfer mechanism 12 in the above-mentioned Embodiment 1, and other symbols are identified by referring to the original symbols or by adding the symbol B. FIG.

[0181] exist Figure 14 Among them, on the first substrate surface 43 of the circuit board 40B, a heating part 43Ba is mounted, and the heating part 43Ba is composed of a heating element 43Bb mounted on a die pad 46B as a heat transfer member and a plurality of surface connection electrodes 45, 45. The connection electrodes 45 and 45 are connected by soldering to the wiring pattern 48c provided on the first substrate surface 43 of the circuit board 40B.

[0182] The circuit board 40B is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com