Repair technology and preparation technology of tubular PERC solar cell

A solar cell, tubular technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as long residence time and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

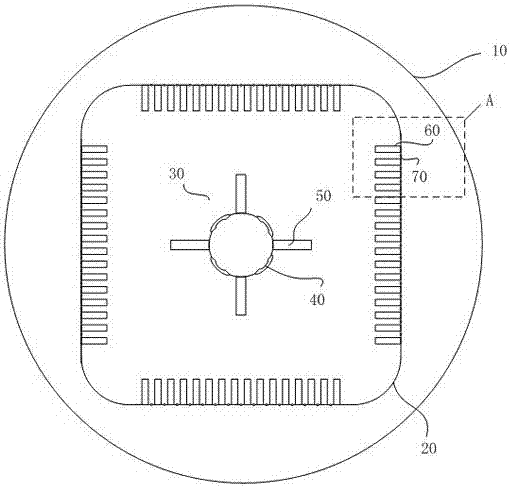

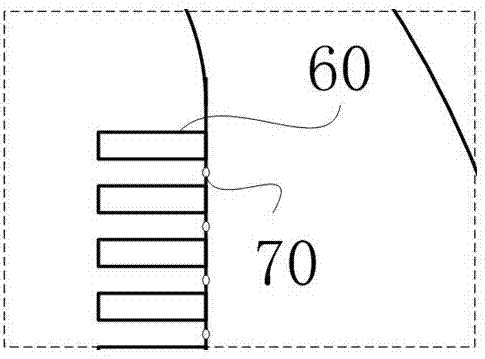

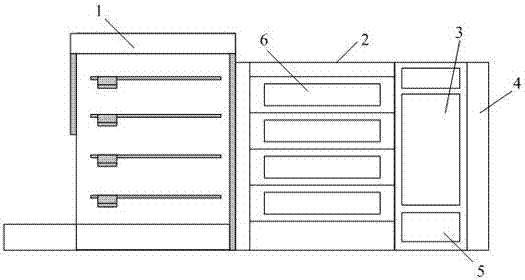

[0076] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0077] The preparation method of existing tubular PERC solar cell comprises the following steps:

[0078] (1) Form a suede surface on the front and back of the silicon wafer, and the silicon wafer is P-type silicon.

[0079] (2) Diffusion is performed on the front side of the silicon wafer to form an N-type emitter.

[0080] (3) Remove the phosphosilicate glass and surrounding PN junctions formed during the diffusion process, and polish the back of the silicon wafer.

[0081] (4) Anneal the silicon wafer.

[0082] (5) Deposit the back composite film on the back of the silicon wafer.

[0083] (6) Depositing a passivation film on the front side of the silicon wafer, the passivation film is preferably a silicon nitride film.

[0084] (7) Laser groove the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Slope angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com